Device for preparing impregnated paper of decorative plate with imitation metal surface

A technology for surface decoration and preparation device, which is applied to the device for coating liquid on the surface, the spray device, the pretreatment surface, etc. Improves aesthetics and usability, and achieves a uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

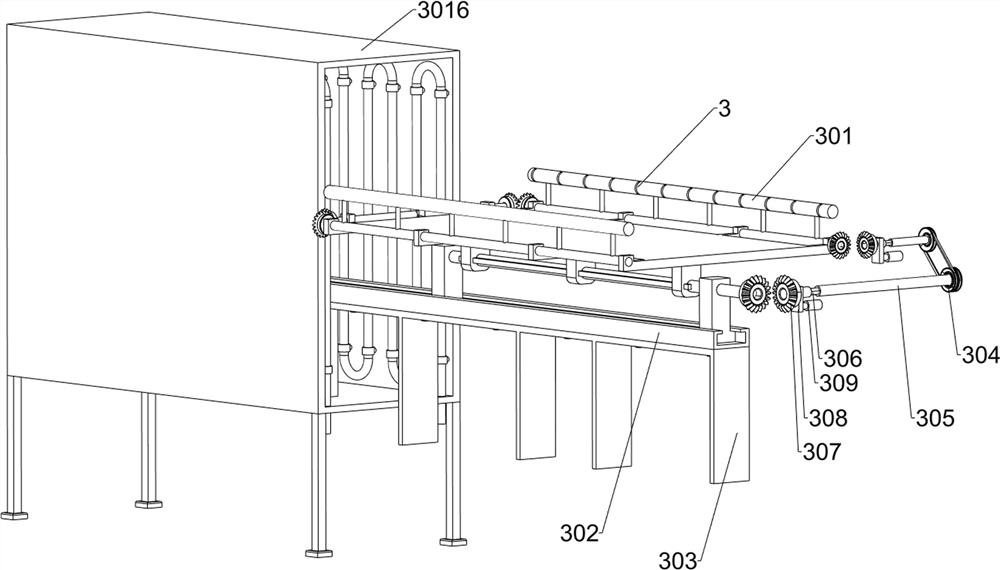

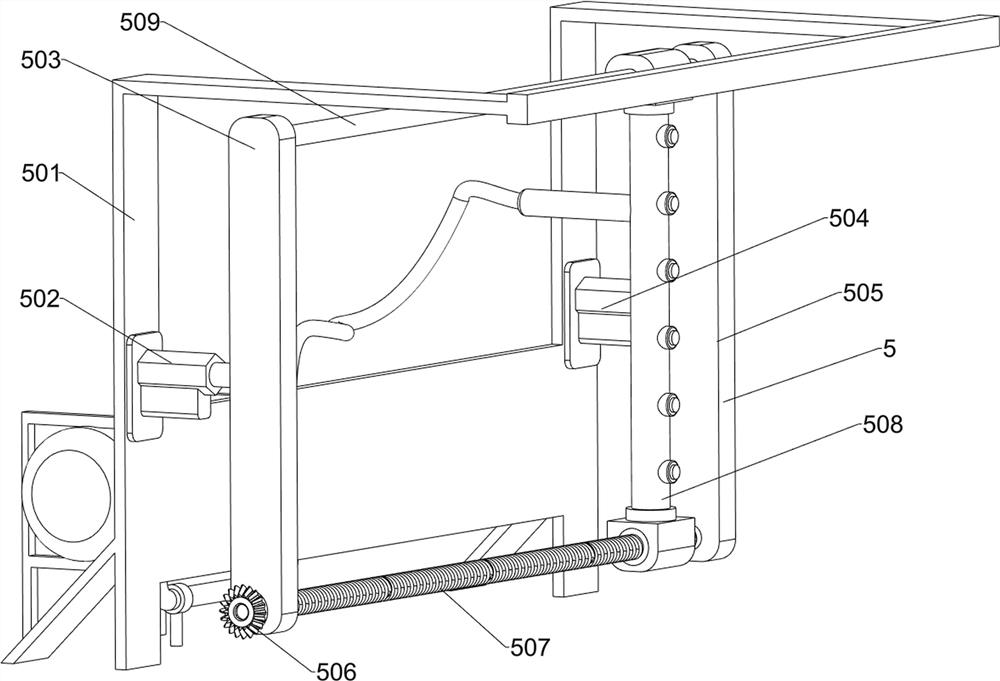

[0034] An immersion paper preparation device for imitation metal surface decorative panels, such as Figure 1-12 As shown, including the support bottom plate 1, the control screen 2, the transfer drying system 3, the upper glue system 4, and the spraying system 5; the support bottom plate 1 is in turn connected to the transfer drying system 3 and the upper glue system 4; control screen 2 and transport dry The system 3 is connected; the transport drying system 3 is connected to the upper gelatin system 4; the upper glue system 4 is connected to the spray system 5.

[0035] Working process: Before running, install the support bottom plate 1 in the apparatus in a smooth working place, an external power source, and the staff manually operate the control screen 2 startup device, check the operational transmission between each system, and confirm that no operation occurs. After the problem, the device is closed; the external decorative paper conveying device, the operation of the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com