Water-saving demister flushing device based on slurry separation and working method thereof

A slurry separation and flushing device technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of scaling, clogging, difficulty in water balance control, large water consumption for demister flushing, etc. The effect of energy consumption, reduction of flushing water consumption, and saving of flushing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

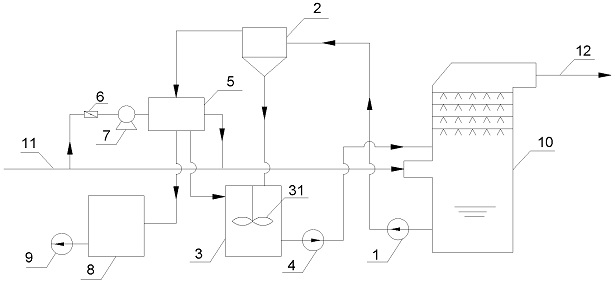

[0030] see figure 1 , in this embodiment, a water-saving demister flushing device based on slurry separation, including a slurry separation pump 1, a slurry separator 2, a thick slurry tank 3, a slurry return pump 4, a flash separation device 5, and a suction fan 7. Flushing water tank 8, flushing water pump 9, desulfurization tower 10 and other equipment.

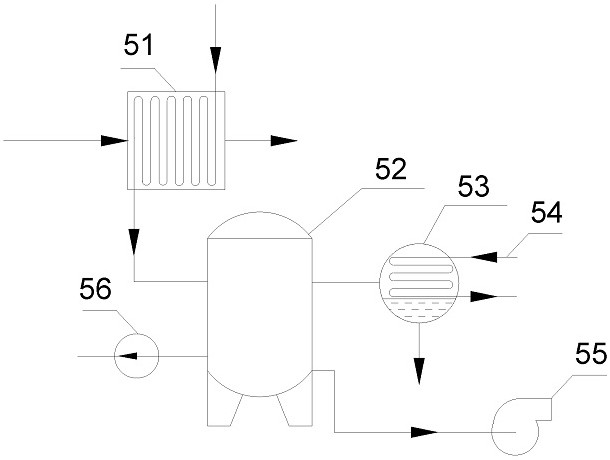

[0031] see figure 2 , The flash separation device 5 includes a flue gas-slurry heat exchanger 51 , a vapor-liquid separator 52 , a condenser 53 , a vacuum pump 55 and a dope pump 56 and other equipment.

[0032] Specifically, the inlet of the slurry separation pump 1 is connected to the slurry outlet of the desulfurization tower 10 , and the desulfurization tower 10 is also connected to a desulfurization inlet flue 11 and a desulfurization outlet flue 12 .

[0033] Specifically, the inlet of the slurry separator 2 is connected to the outlet of the slurry separation pump 1, the top outlet of the slurry separator 2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com