An automatic paper cartoning machine

A technology of cartoning machine and paper sheet, which is applied in the direction of packaging, etc., can solve the problems of affecting the adhesive force between the glue-coated area and the adhesive, affecting the adhesion effect of the paper sheet, and reducing the bonding strength, so as to improve the stability of placement , Improving the effect of sticking and improving the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

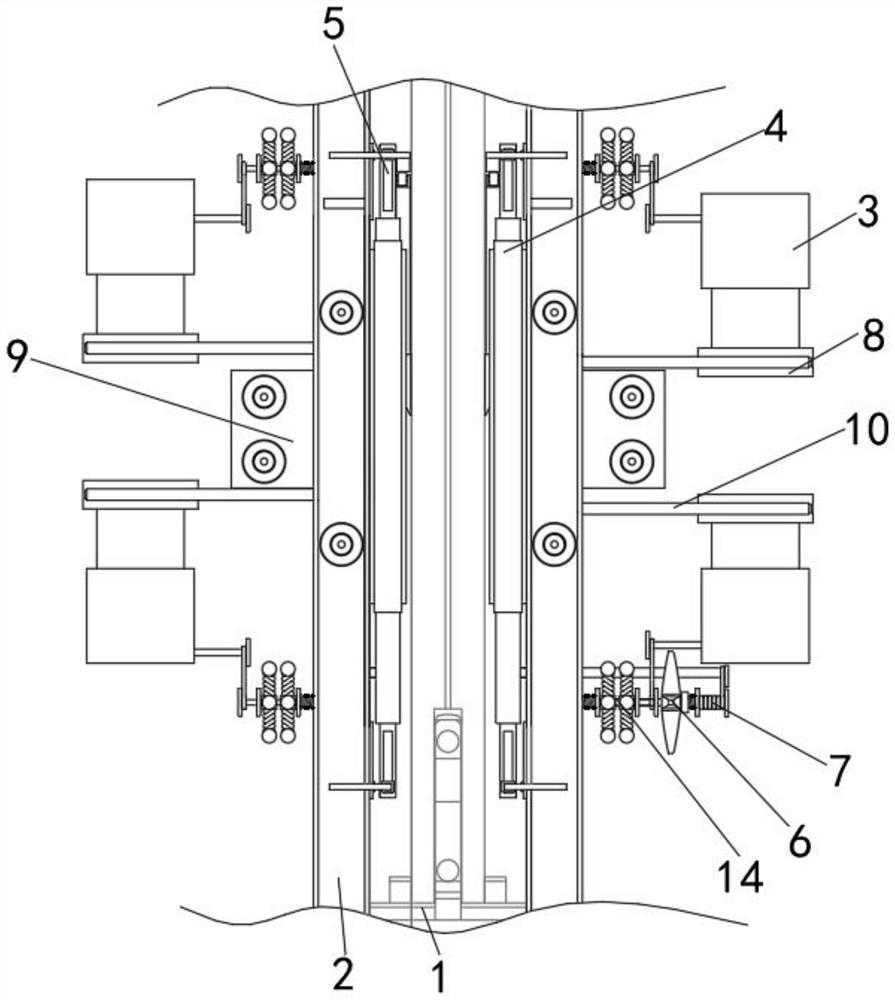

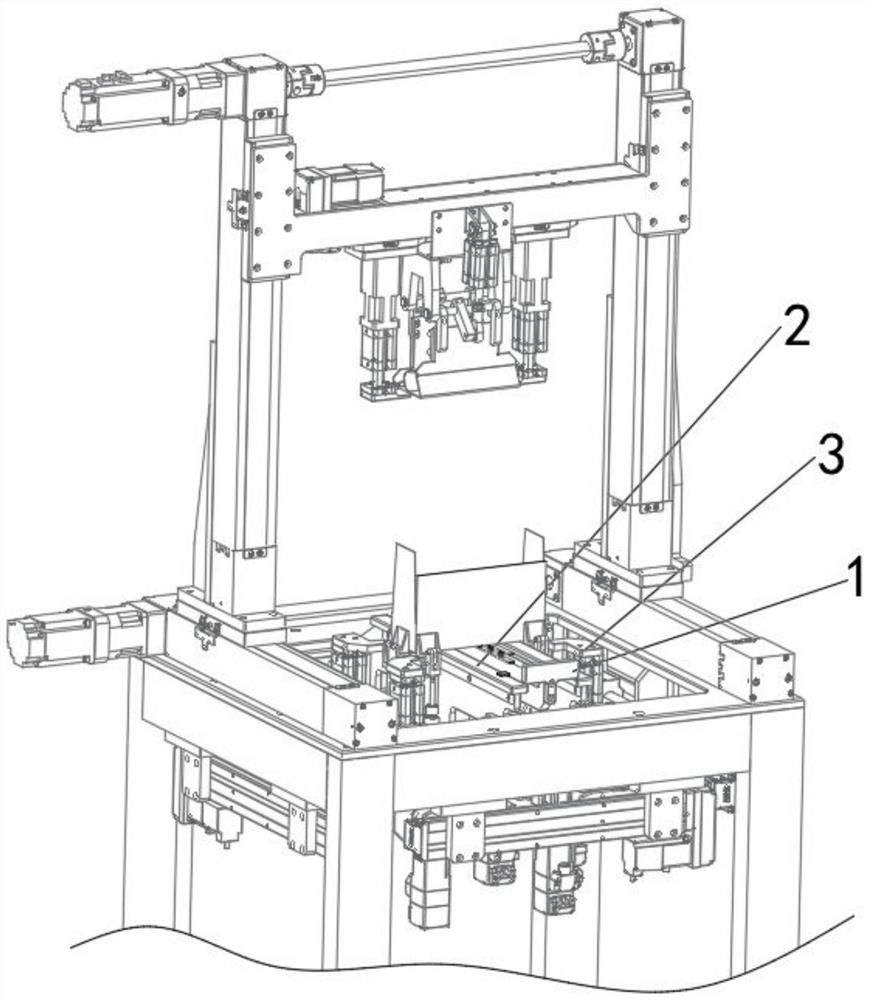

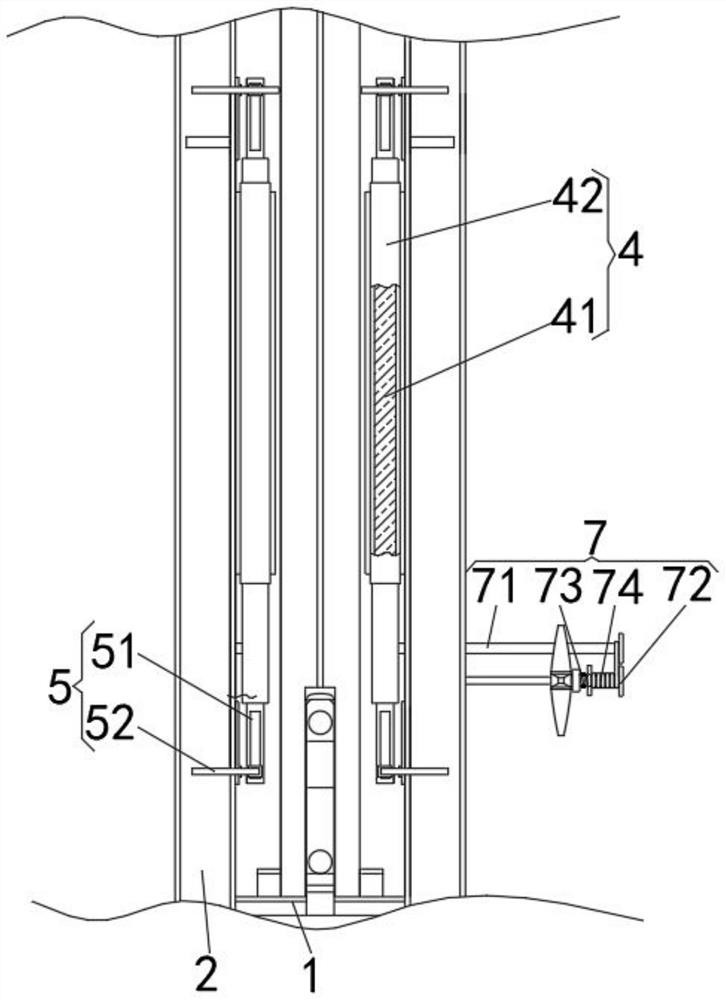

[0032] The box folding equipment in the traditional automatic paper cartoning machine also includes a folding box front and rear mechanism, a folding box side mechanism, a folding box upper tongue mechanism, a folding box cover mechanism, and a pressing mechanism;

[0033] The cartoning steps in the traditional cartoning machine are as follows: Robot 1 sucks the blank plane of the carton to the work surface; Robot 2 puts the packaging material in the center of the bottom of the box, and Robot 1 applies glue on the designated position of the upper box cover; and then folds Box side ears (4 places), front and back of the folded box and the sides of the box at both ends of the folded box, the upper tongue of the folded box (2 places), folded the inner cover, folded the upper cover and the upper inner cover after bonding and then pressed to form, finally The finished packaging box is transported by the air cylinder to the output track to the next station of the production line.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com