Dendrite-free alloy negative electrode with solid-liquid phase conversion mechanism and preparation method of dendrite-free alloy negative electrode

A technology of alloy negative electrode and liquid phase transformation, applied in the direction of negative electrode, electrode manufacturing, battery electrode, etc., to achieve high safety and long cycle stability, high interface stability, and solve the effect of dendrite growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

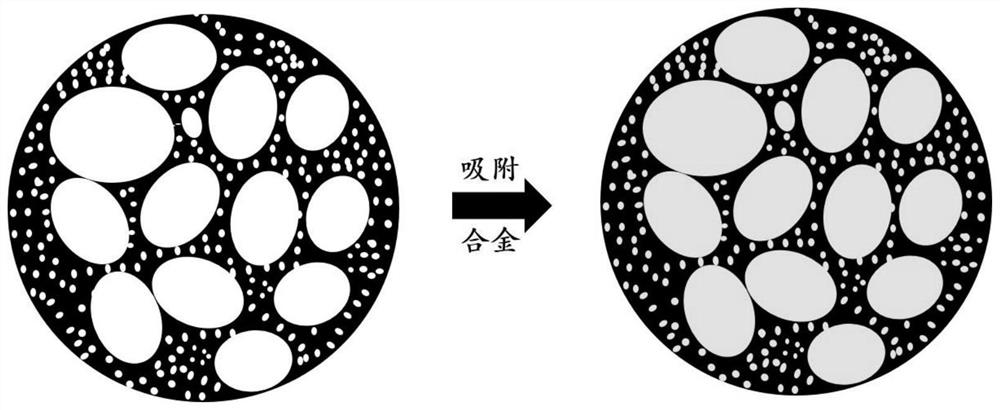

[0030] In this embodiment, the dendrite-free alloy negative electrode with a solid-liquid phase transformation mechanism includes a liquid alloy, a three-dimensional framework compatible with the liquid alloy and having a porous structure. Such as figure 1 As shown, the alloy negative electrode is introduced into the pores of the porous carbon material in the molten state, and the molten liquid phase alloy negative electrode is fixed by relying on the pore size and capillary action. The mass ratio of the alloy to the skeleton can be realized by adjusting the porosity of the skeleton, and can be adjusted between 5-95wt.%.

Embodiment 2

[0032] figure 2 Shown is a schematic diagram of the solid-liquid two-phase transition mechanism of the alloy negative electrode in the charging and discharging process of the battery (taking Na-K two-phase alloy as an example). Both the initial charging state and the discharging cut-off state exist in the form of solid phase (1). During the charging process, sodium ions get electrons on the surface of the alloy negative electrode to precipitate metal sodium, the ratio of phase elements on the surface of the alloy negative electrode changes, and the surface phase of the alloy negative electrode changes from solid phase to molten liquid phase state. With the further increase of sodium in the alloy ratio Large, the alloy phase of the negative electrode gradually changes from the surface to the interior of the bulk phase into a molten liquid phase until the overall phase composition of the sodium alloy negative electrode reaches (2) Charging is terminated. During the entire chargi...

Embodiment 3

[0034] The porous carbon material is used as the matrix, and the graphene surface modification of the porous carbon material is carried out by means of in-situ surface modification, and a three-dimensional skeleton with a porous structure compatible with the liquid alloy is prepared; an appropriate amount of Na and K are placed together, and in Heating to above 70°C in an inert atmosphere, and keeping it warm for 1-10 hours to fully mix the metals, then cooling the alloy to room temperature to obtain the target alloy, and placing a three-dimensional skeleton with a porous structure in the melted alloy at 300-1000°C , make it adsorb the liquid alloy, and after the holes are completely filled with the alloy, take it out from the liquid alloy, cool to room temperature, and obtain the alloy negative electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com