Self-adaptive track for inspection robot of fully mechanized coal mining face

A technology for inspection robots and fully mechanized mining faces, applied in the direction of supporting machines, manipulators, mechanical equipment, etc., can solve problems such as manual inspection safety hazards, improve accuracy, improve automation level, and realize fewer or no people The effect of homework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

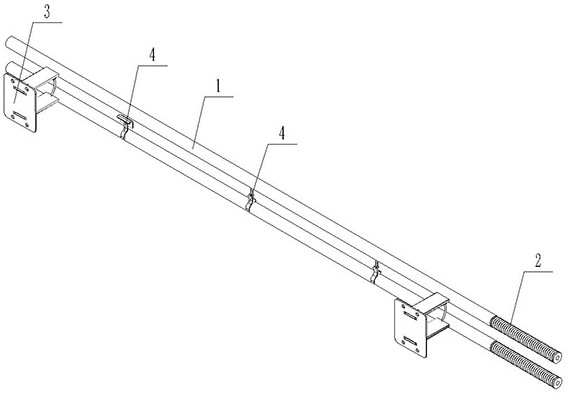

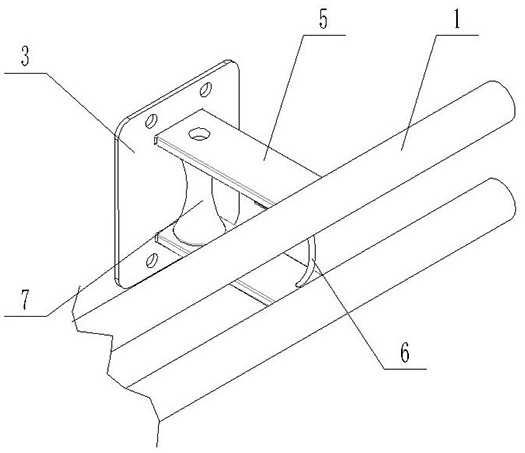

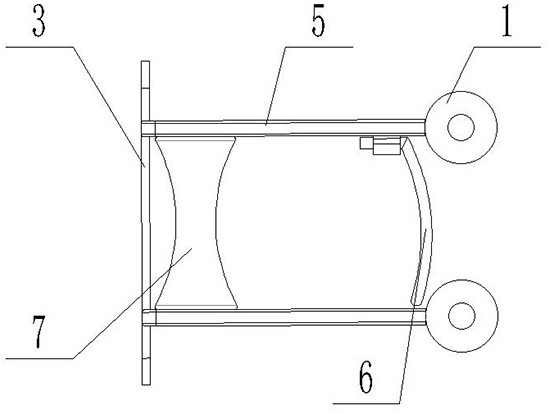

[0018] Such as Figure 1 to Figure 6 As shown, the present invention is an adaptive track for a fully mechanized mining face inspection robot, including a plurality of track bodies 1, elastic connectors 2, support frames 3 and limit blocks 4, one side of the support frame 3 For fixing on the scraper machine, the other side of the support frame 3 is provided with two vertically parallel baffles 5, one end of the two baffles 5 is fixedly arranged on the support frame 3, and the two baffles The other end of the plate 5 is provided with a track body 1, the two track bodies 1 are arranged in parallel up and down, and an arc-shaped gap is movably arranged between the two baffle plates 5 at the end on one side of the track body 1. One-way bar 6, between the two baffle plates 5, at the end on one side of the support frame 3, a rotary body roller 7 with a concave waist is movably provided, and the rotary body roller 7, the two baffle plates 5 and The channel formed by the cooperation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com