Overhanging type cable winding mechanism and method applied to reciprocating type rotary table

A reciprocating and hanging technology, which is applied to the arrangement of reels/photosensitive drums, the transportation of filamentous materials, and the handling of thin materials. It can solve the needs of unsuitable cable winding protection and the inconvenience of cable installation and maintenance. , Occupying large axial dimensions and other issues, to achieve good practicability, simple structure, and reduce torsional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

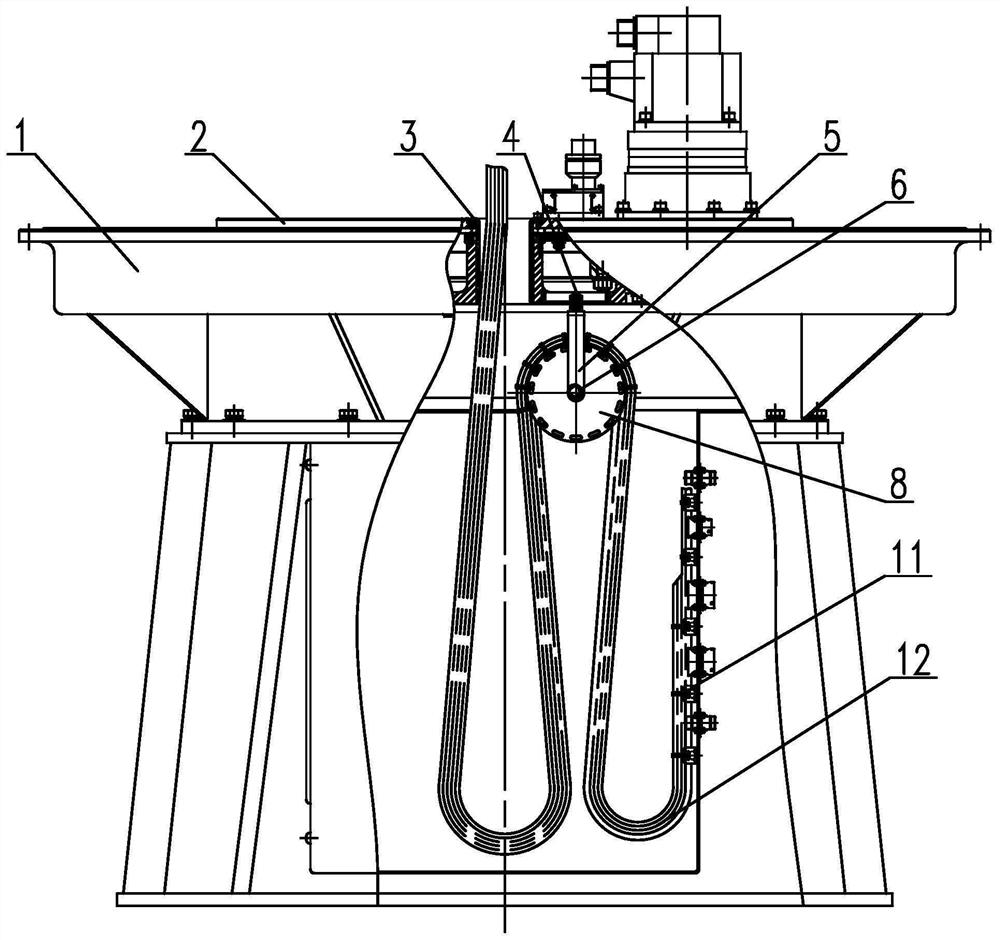

[0047] In this embodiment, a suspension-type cable winding mechanism applied to a reciprocating turntable is specifically provided to solve the application requirements of the turntable while reducing the torsional deformation of the cable 12 itself, so that the limit rotation angle range is not less than ±360° cable 12 coiling and protection functions. The suspension cable winding mechanism is mainly used in reciprocating turntables, such as figure 1 As shown, the reciprocating turntable includes a turntable fixed part 1 and a turntable rotating part 2, the turntable rotating part 2 is arranged coaxially with the turntable fixed part 1, and the turntable rotating part 2 performs rotational movement relative to the turntable fixed part 1 to realize The application function requirements of the corresponding equipment on the rotating part 2 of the turntable.

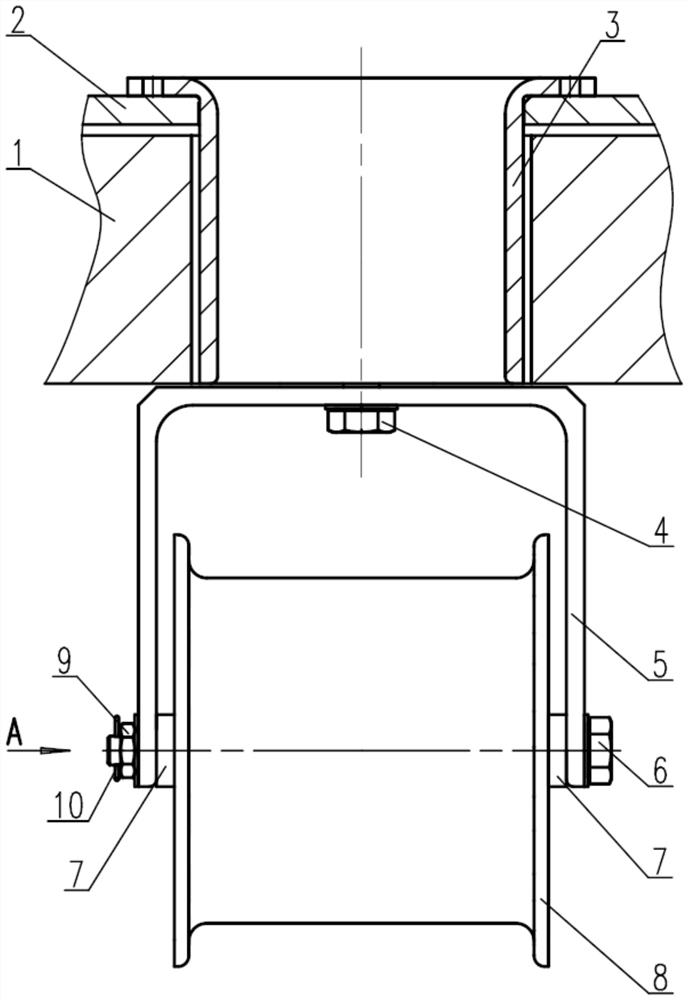

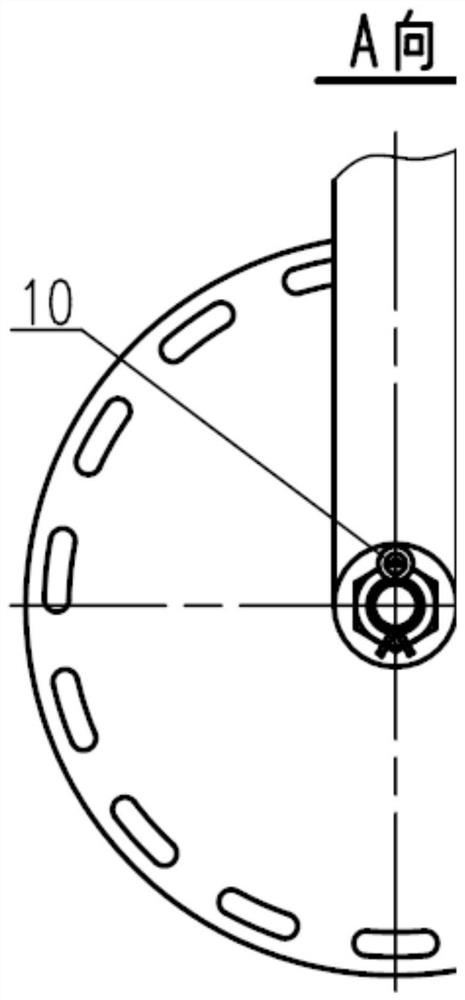

[0048] The winding mechanism mainly includes three parts: a central sleeve 3, a suspension frame and a winding wheel 8,...

Embodiment 2

[0064] Based on the suspension cable winding mechanism applied to the reciprocating turntable provided in Embodiment 1, on the basis of the winding mechanism, this embodiment also provides a suspension cable winding mechanism applied to the reciprocating turntable A winding method, the winding method comprising:

[0065] S1: Pass the cable 12 downward through the cable hole 34 of the center sleeve 3 located in the middle of the rotating part 2 of the turntable;

[0066] S2: Keep the cable 12 hanging naturally. The natural hanging length of the cable 12 can be specifically determined according to the allowable torsional deformation angle of the cable 12 and the limit angle range of the reciprocating turntable. In this embodiment, the hanging is 400mm-500mm, and the curvature is selected. A reel with a radius not lower than the minimum safe bending radius of the cable being wound, and passing the end of the cable 12 upward through the reel 8;

[0067] S3: Pass the binding hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com