Conveyor transfer unit based on core press

A press and magnetic core technology, applied in the field of conveying and transferring units, can solve problems such as poor production effects, achieve better use effects, reduce labor costs, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

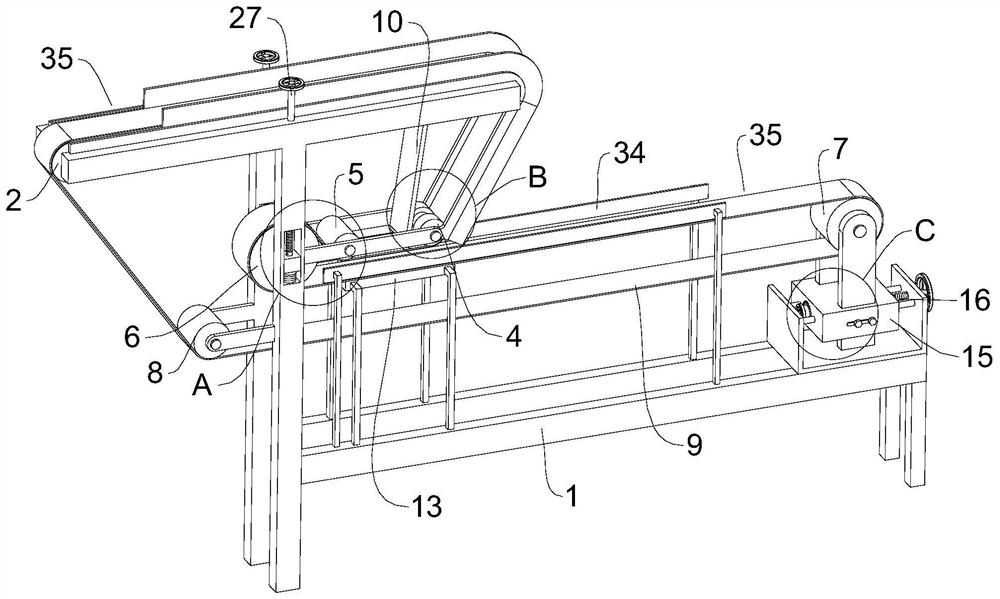

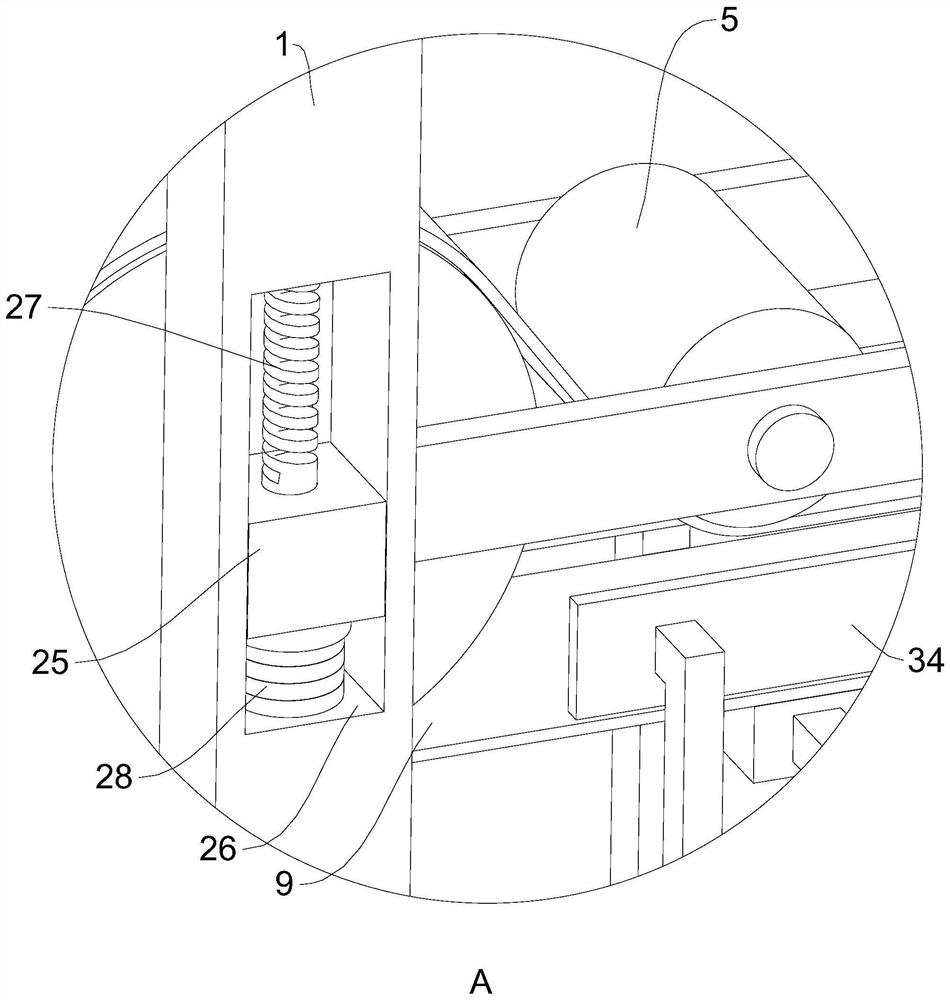

[0046] A conveying transfer unit based on a magnetic core press, such as Figure 1 to Figure 12 shown, including bracket 1 as well as,

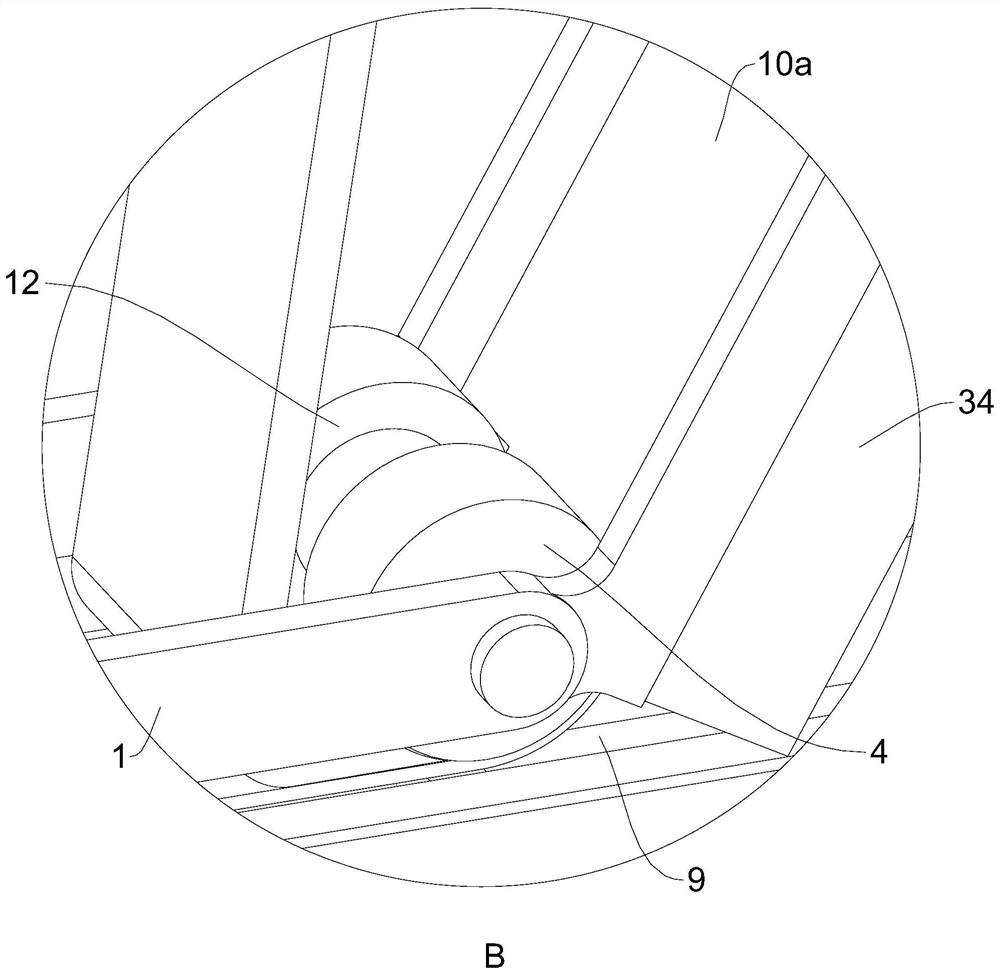

[0047] The first turning roller 2, the second turning roller 3, the third turning roller 4, the fourth turning roller 5, the fifth turning roller 6, the sixth turning roller 7 and the seventh turning roller 8 which are rotatably connected to the support 1 , wherein the top of the first turning roller 2 is at the same height as the top of the second turning roller 3, the bottom of the third turning roller 4 is at the same height as the bottom of the fourth turning roller 5, and the fifth The top of turning roller 6 is higher than the top of described fourth turning roller 5, the bottom of described fifth turning roller 6 is equal to the top of described sixth turning roller 7, the top of described first turning roller 2, all The heights of the bottom of the third turning roller 4 and the top of the sixth turning roller 7 decrease successively...

Embodiment 2

[0084] A conveying and transferring unit based on a magnetic core press, the difference from Embodiment 1 is that both the second turning roller 3 and the third turning roller 4 are made of magnetic materials.

[0085] In this way, first of all, the second turning roller 3 and the third turning roller 4 can better support the conveyor belt 9, which prevents or reduces wear between the conveyor belt 9 and the positioning magnet 10, and can also fully absorb the green body, The position stability and transfer stability of the green body are guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com