Motor and rotor core thereof

A rotor core and stator core technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of air resistance, oily aluminum slag, and oxidation slag that cannot be discharged, so as to achieve increased tightness, stable performance, and improved The effect of motor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

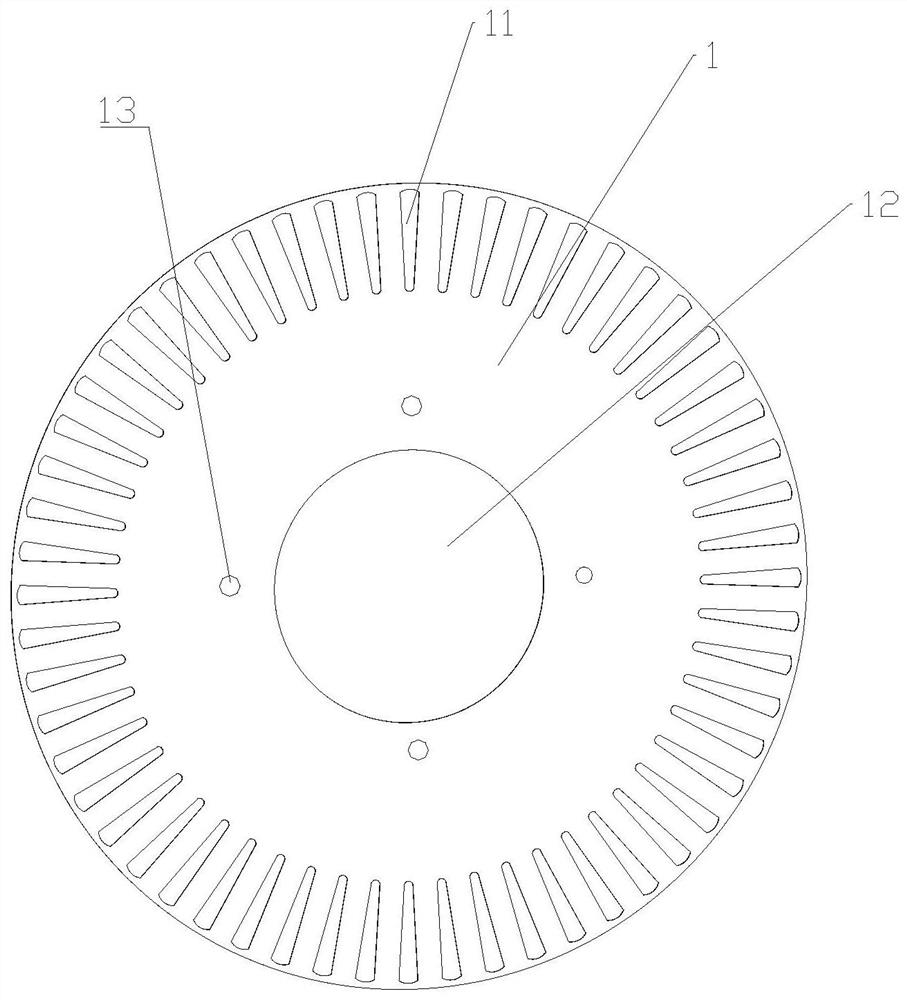

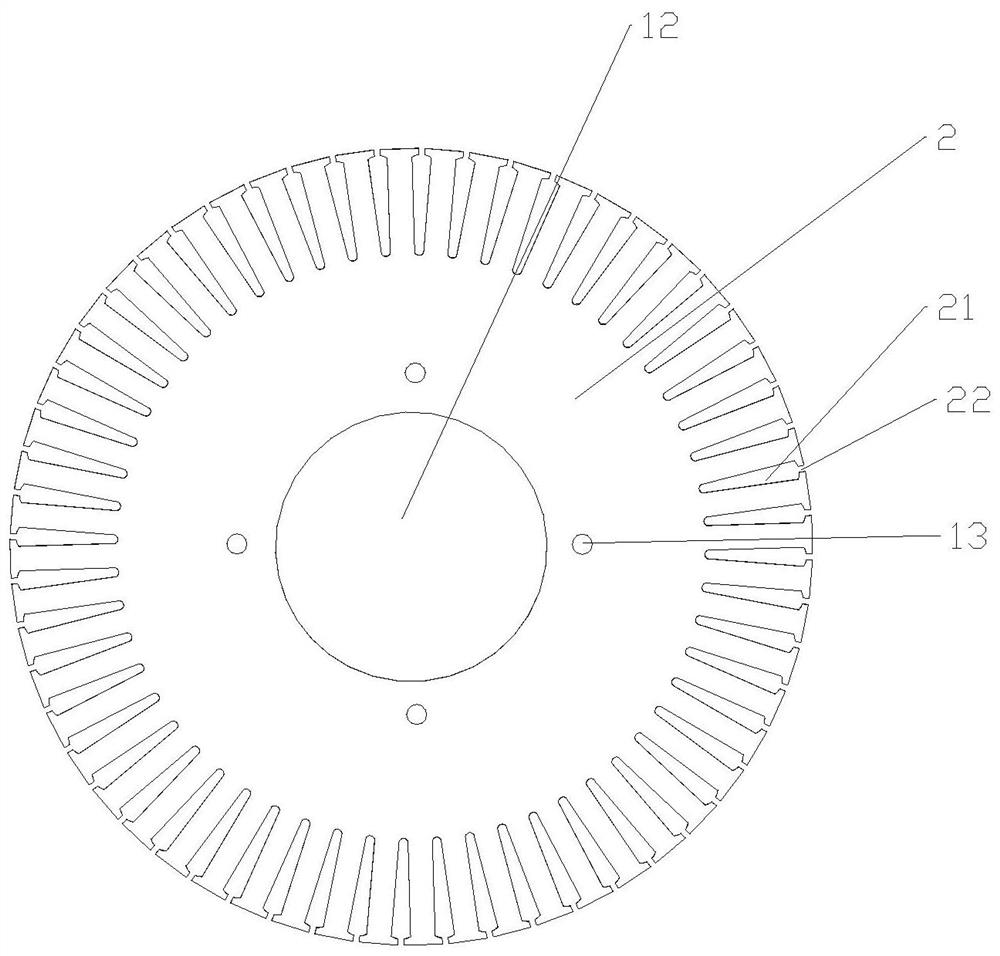

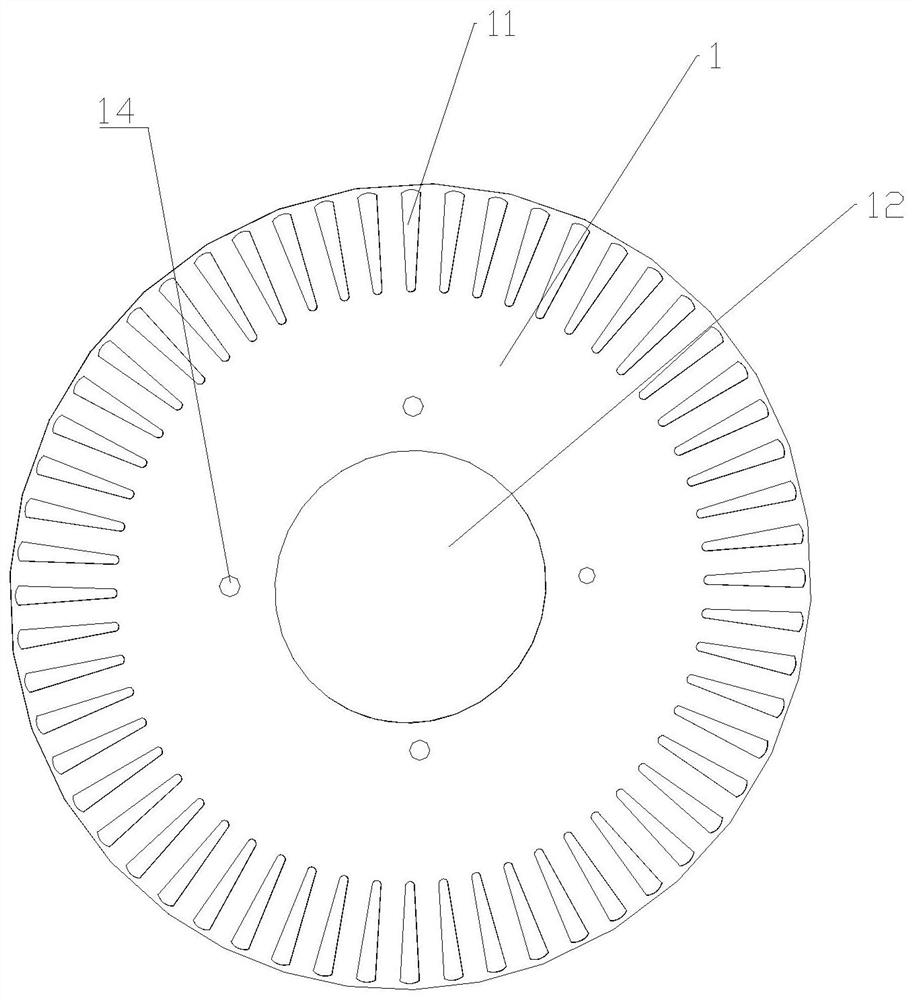

[0031] combined with Figure 1-6 , the rotor core of this embodiment includes a plurality of stacked first chips 1 and second chips 2, the first chips 1 and the second chips 2 are alternately arranged, and the first chips 1 have a plurality of First guide grooves 11 distributed in the circumferential direction, the second chip 2 has a plurality of second guide grooves 21 distributed along its circumference, the outer wall of the second chip 2 has an opening 22 extending to the second guide grooves 21 . The setting of the opening 22 enables the gas inside the rotor core, as well as impurities such as aluminum slag and oxide slag to be discharged in time, so that the performance of the rotor core is stable, not easily deformed, and the performance of the motor is improved.

Embodiment 2

[0033] combined with Figure 1-6 , Compared with the technical solution of Embodiment 1, the rotor core of this embodiment can be improved as follows: the number of the first chips 1 is greater than the number of the second chips 2 . The number of the first chips 1 is greater than the number of the second chips 2 to ensure the electromagnetic performance of the motor.

Embodiment 3

[0035] combined with Figure 1-6 , Compared with the technical solution of Embodiment 1 or 2, the rotor core of this embodiment can be improved as follows: the materials of the first chip 1 and the second chip 2 are silicon steel sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com