Alignment adjustment method of blocking component, controller and gate equipment

An adjustment method and a technology of blocking parts, which are applied in the direction of electric speed/acceleration control, etc., to achieve the effects of saving hardware costs, simple operation, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

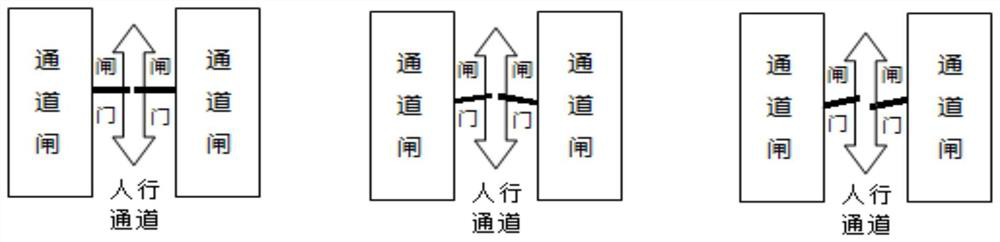

[0057] In order to make the purpose, technical means and advantages of the present application, the present application will be further described below with reference to the accompanying drawings.

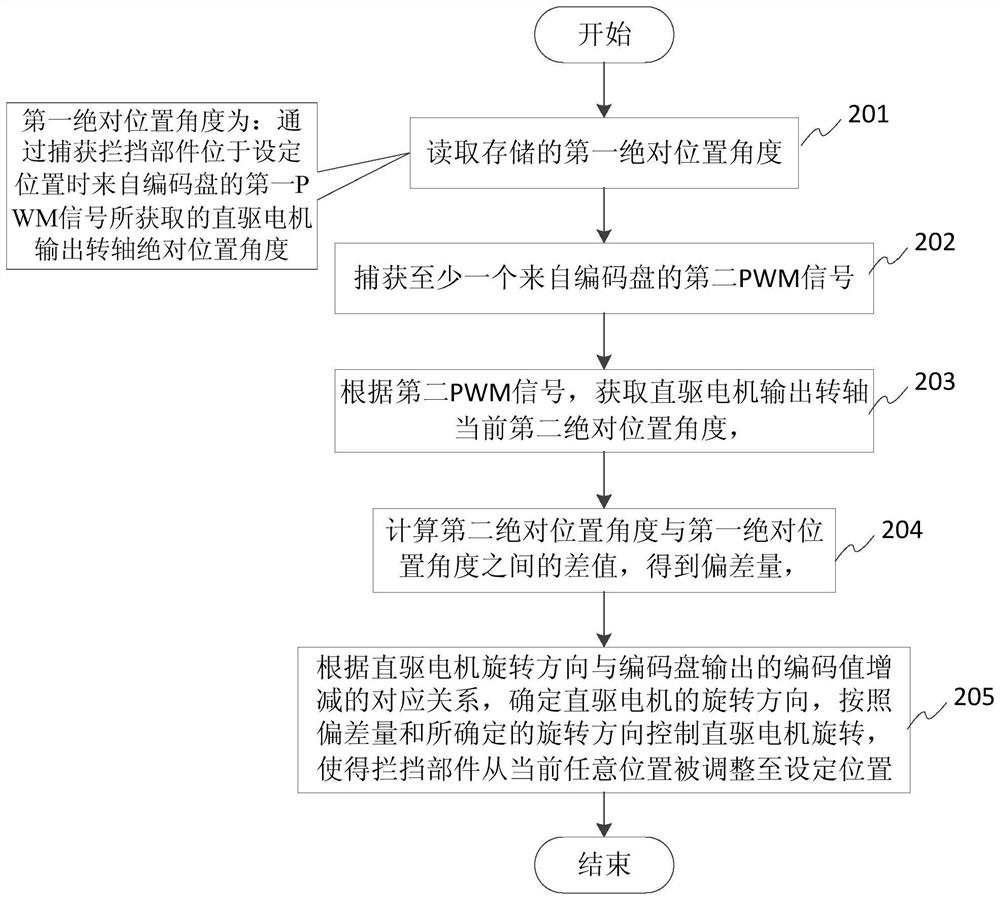

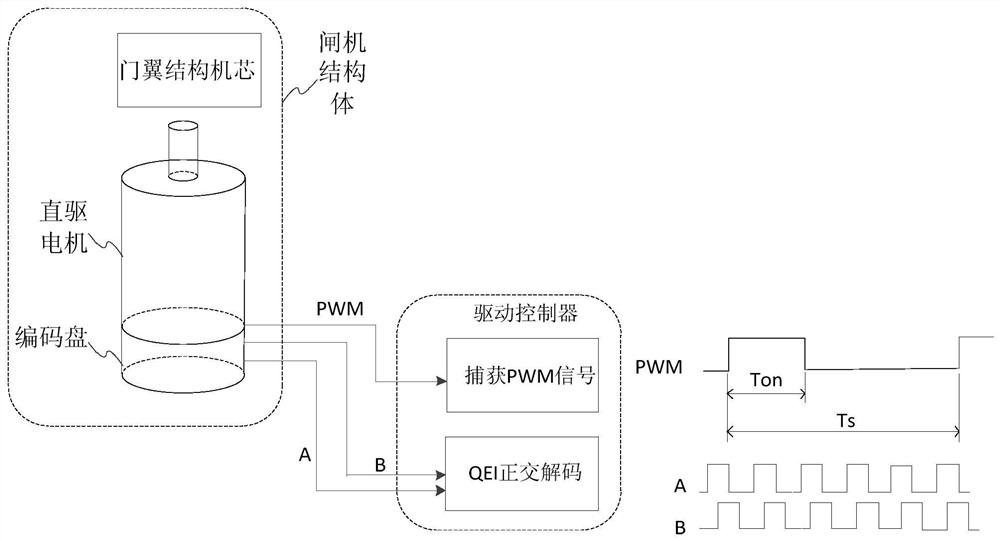

[0058] The present application is recorded by the first absolute position angle of the direct drive motor output rotating shaft when the shutter member is located in the set position, and then the second absolute position angle of the direct-drive motor output rotation axis is in the current arbitrary position. The difference between the absolute position angle, controls the direct drive motor rotation, so that the shuttle member is adjusted from the current any position to the set position, wherein the first absolute position angle, the second absolute position angle is attached to the direct drive motor output by capturing The PWM signal output from the shaft is determined.

[0059] See figure 2 Distance figure 2 A flow diagram of an alignment adjustment method of an intercepting mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com