A high-sensitivity impact cap for a fuze

A high-sensitivity, flasher technology, used in fuzes, offensive equipment, weapon accessories, etc., can solve the problems of weak bottom strength, difficulty in improving trigger sensitivity, and inability to meet the requirements of high trigger sensitivity, and achieve the effect of improving structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

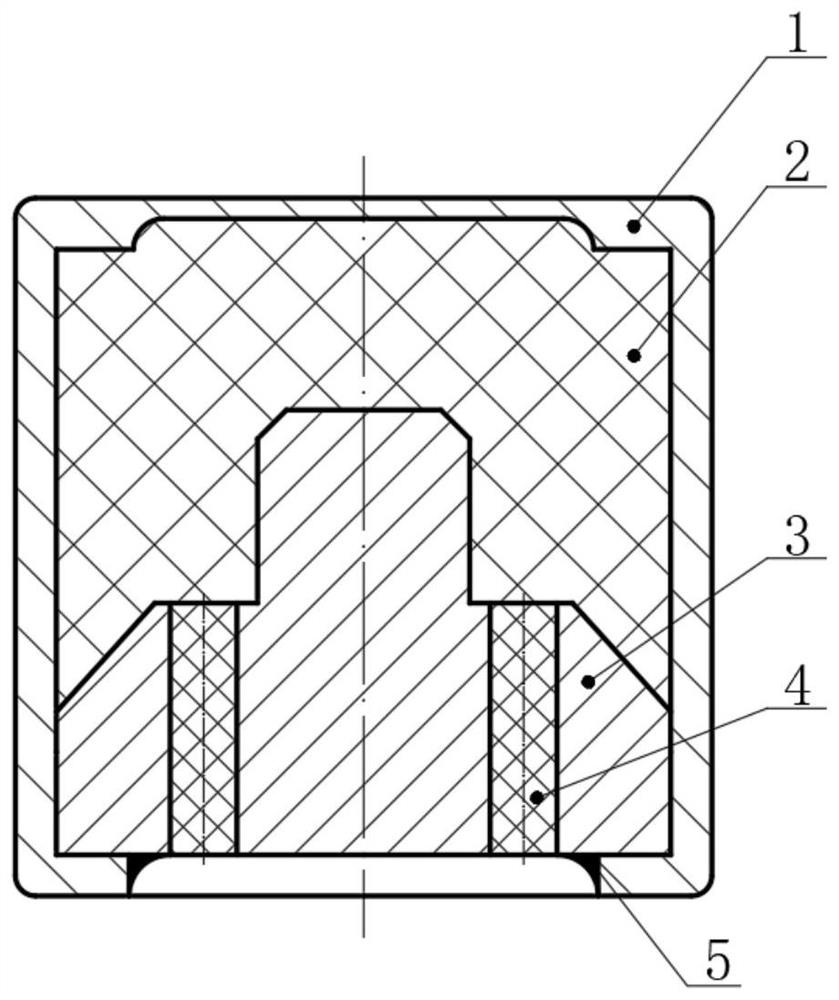

[0016] combine Figure 1 , a kind of induction credit high sensitivity impact fire cap of the present invention, comprising a tube shell 1, a fire cap agent 2 and a pad 3, the tube shell 1 is barrel-shaped, the closed end of the barrel as the input end, the open end as the output end, the input end center to do thinning treatment, easy to excite; the fire cap agent 2 and the pad holder 3 are disposed from top to bottom inside the tube shell 1, the fire cap agent 2 is in contact with the input end, the output end is closed to fix the pad 3, and sealed by sealing paint 5, the pad 3 is composed of several cylinders connected sequentially from top to bottom, The diameter of the cylinder increases from top to bottom, the topmost one is the first order cylinder, sorted downwards sequentially, from the bottom of the base 3 to the top surface of the second order cylinder is opened with N through holes, N = 4 to 8, N through holes about the first order of the cylinder equal spacing is a cir...

Embodiment 2

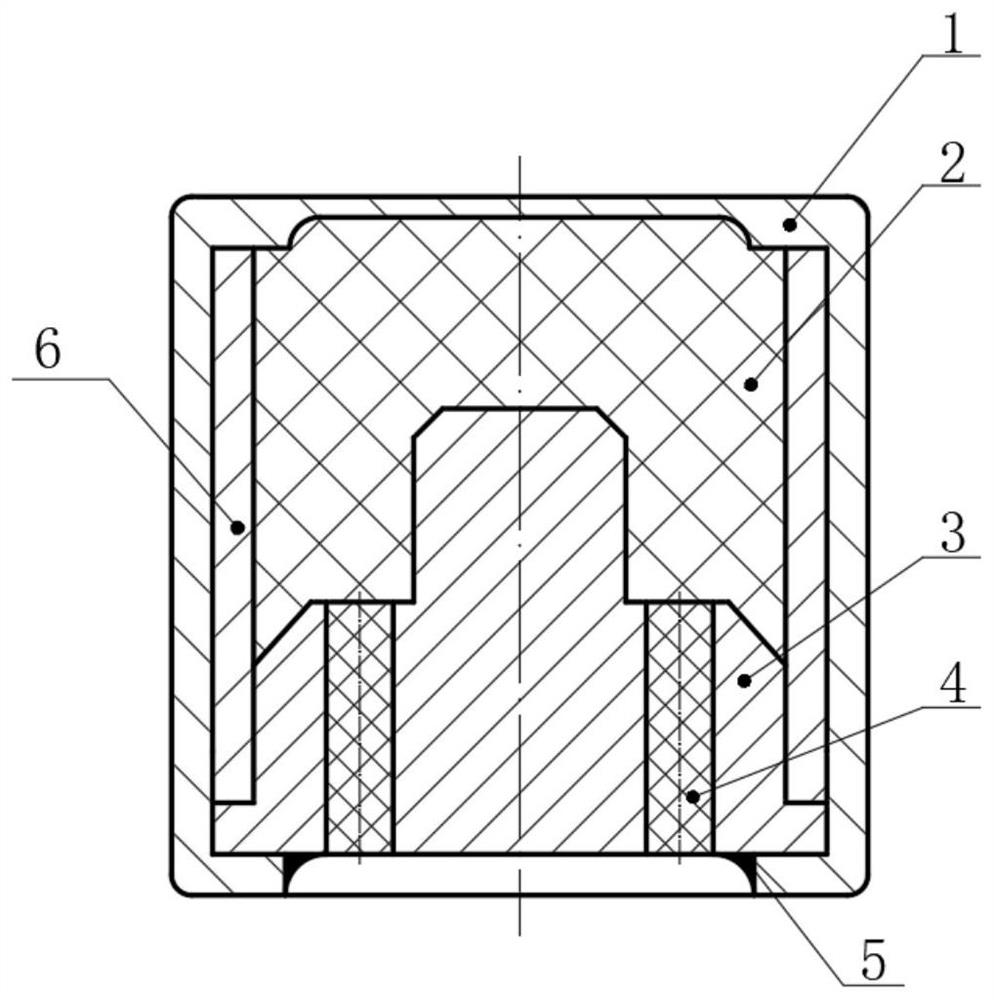

[0019] combine Figure 2 , a kind of induction credit high sensitivity bumper fire cap of the present invention, comprising a tube shell 1, a fire cap agent 2, a gasket 3 and a support cylinder 6, the tube shell 1 is barrel-shaped, the closed end of the barrel is used as the input end, the open end is used as the output end, the input end center is thinned, which is convenient for excitation; the fire cap agent 2 and the pad 3 are disposed from top to bottom within the tube shell 1, the fire cap agent 2 is in contact with the input end, the output end is closed to fix the pad 3, and sealed by sealing paint 5, the pad 3 is composed of a number of cylinders connected sequentially from top to bottom, The diameter of the cylinder increases from top to bottom, the topmost one is the first order cylinder, sorted downwards sequentially, from the bottom of the base 3 to the top surface of the second order cylinder is opened with N through holes, N = 4 to 8, N through holes about the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com