Mechanism for synchronously supplying shots to double pipelines

A dual-pipeline technology, applied in ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of low frequency of ammunition supply, complex mechanism, space occupation, etc., and achieve low jamming rate, small size, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

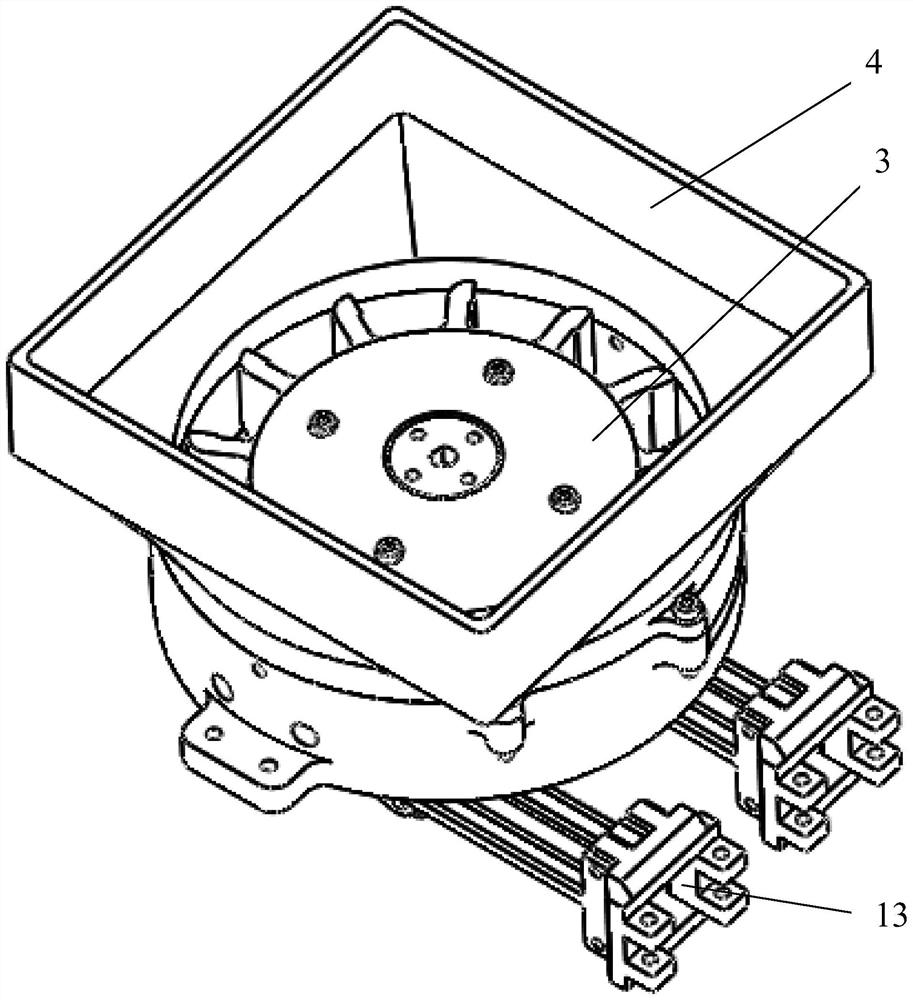

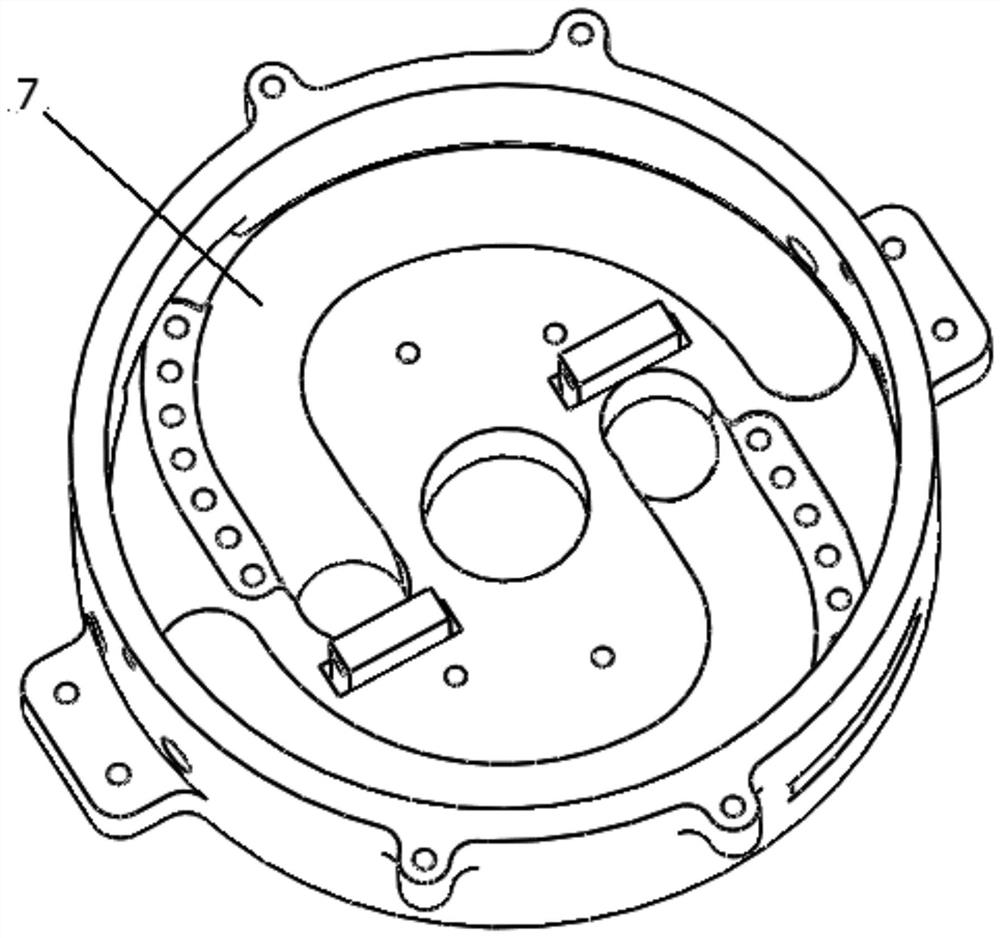

[0029] In this embodiment, a mechanism for synchronously supplying pellets with double pipelines, such as Figure 1-2 As shown, it includes a magazine, a plucking device, a cartridge and two pipelines arranged in sequence from top to bottom. The structure of the two pipelines is the same, and both pipelines are connected with the cartridge. The magazine falls onto the bullet tray, and the bullet in the bullet tray is dialed to two pipelines by the said picking device and then sent out.

[0030] Such as figure 2 As shown, the picking device includes a driving rod 1, a driving motor 9 and a flange 2, the driving motor is connected to the driving rod through the flange, and the driving motor drives the driving rod to rotate.

[0031] The driving lever includes a dial 3 and a dial arm, a plurality of radial dial arms are arranged on the outer periphery of the dial, and a slope that is high in the middle and low in the periphery is set on the upper surface of the dial.

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com