A binary nozzle structure for ejecting cold air from the engine compartment

A technology of engine compartment and binary nozzle, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problem of excessive infrared radiation of nozzles, achieve the effects of ensuring stealth characteristics, improving infrared stealth performance, and reducing infrared radiation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

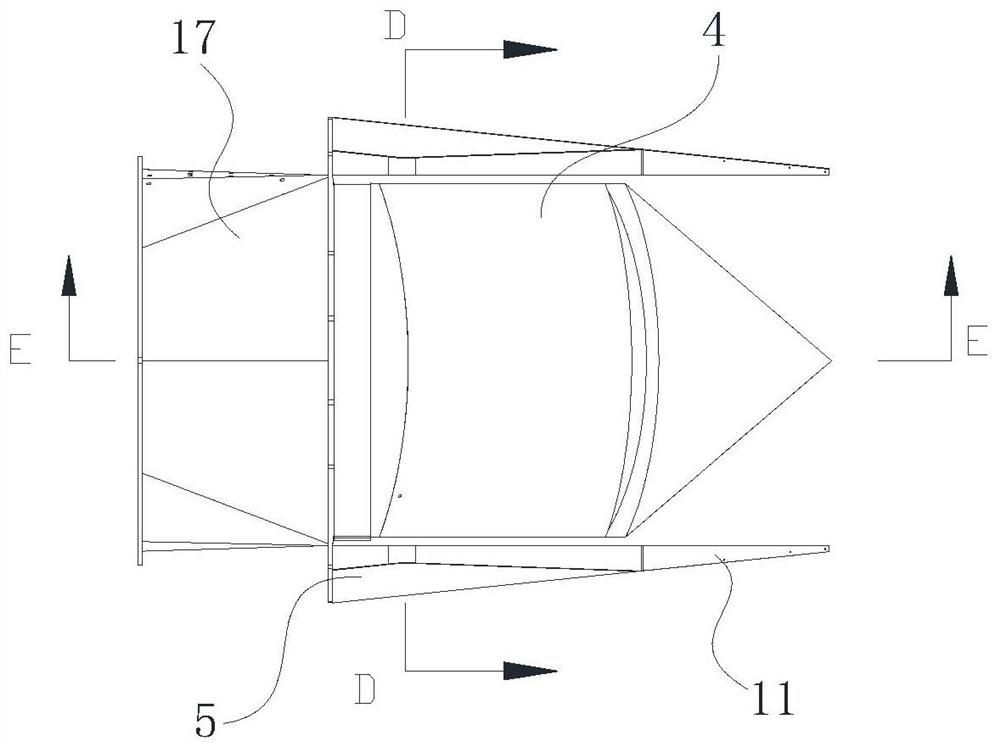

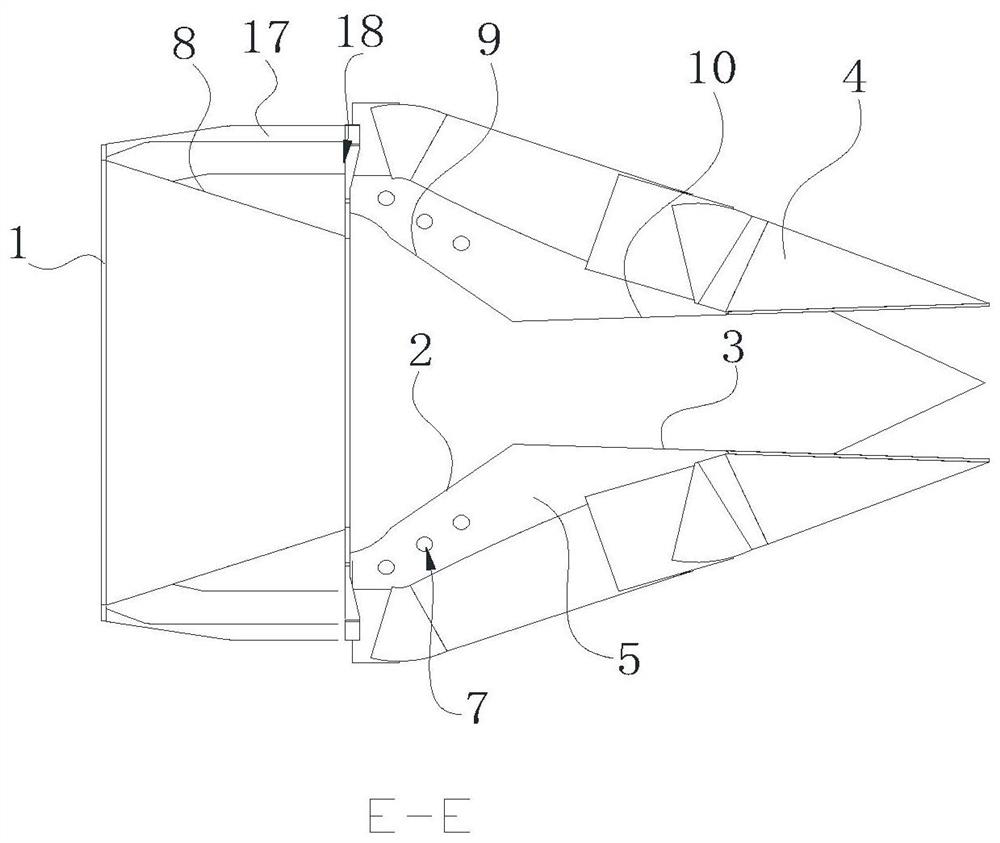

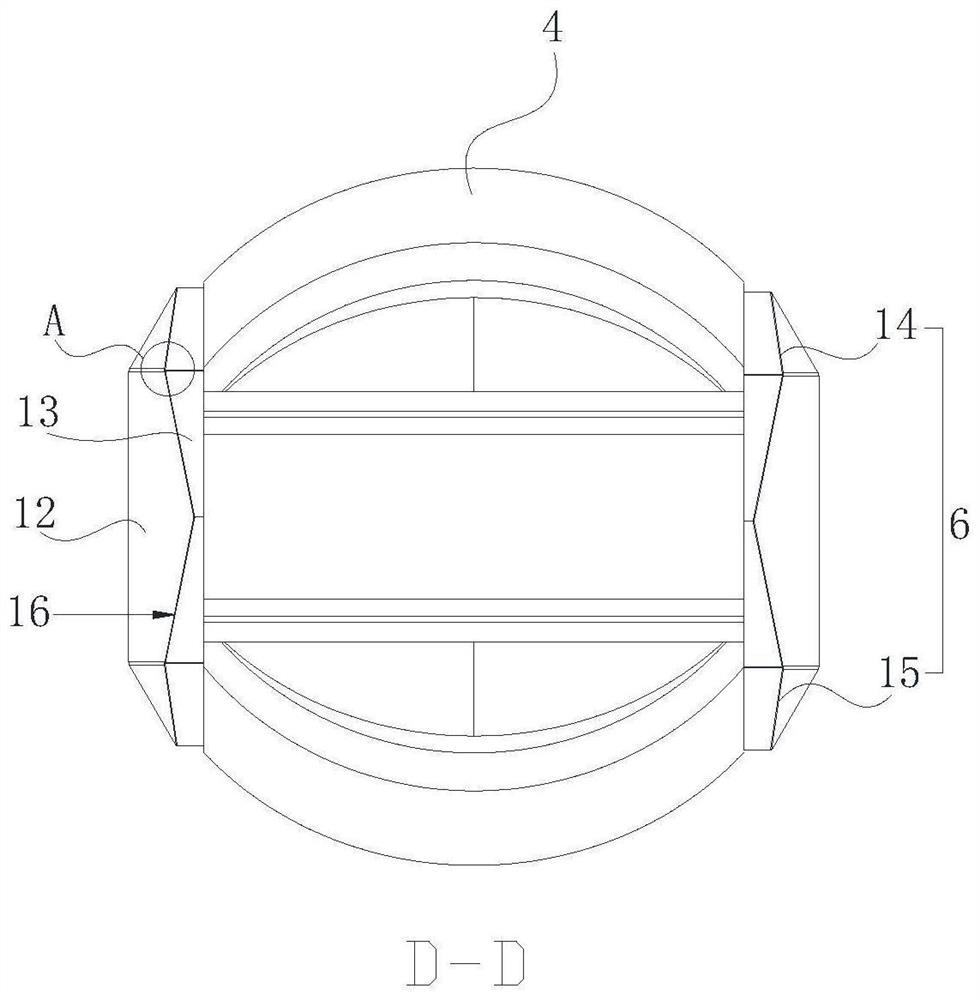

[0026] As a specific implementation manner, a binary nozzle structure for ejecting cold air from an engine compartment includes a circular turning section 1 , a converging section 2 and an expanding section 3 .

[0027] The inlet end of the rounded square section 1 is a circular structure, the outlet end is linearly reduced along the circular structure, and gradually becomes a square structure, and the size of the inlet is larger than that of the outlet end, and the convergent section 2 is linear from the inlet end to the outlet end. It gradually shrinks to form a throat, and the expansion end increases linearly from the inlet end to the outlet end to form a jet pipe. The outlet of the rounded section 1 communicates with the inlet of the converging section 2 , and the outlet of the converging section 2 communicates with the inlet of the expanding section 3 .

[0028] When the static pressure of the airflow expanding to the nozzle outlet is exactly equal to the external atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com