Spring marking method and system

A target and workpiece technology, applied in the field of marking, can solve the problems of large occupied space, etc., and achieve the effect of realizing space, reducing the horizontal area of the factory building, and rationally using it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

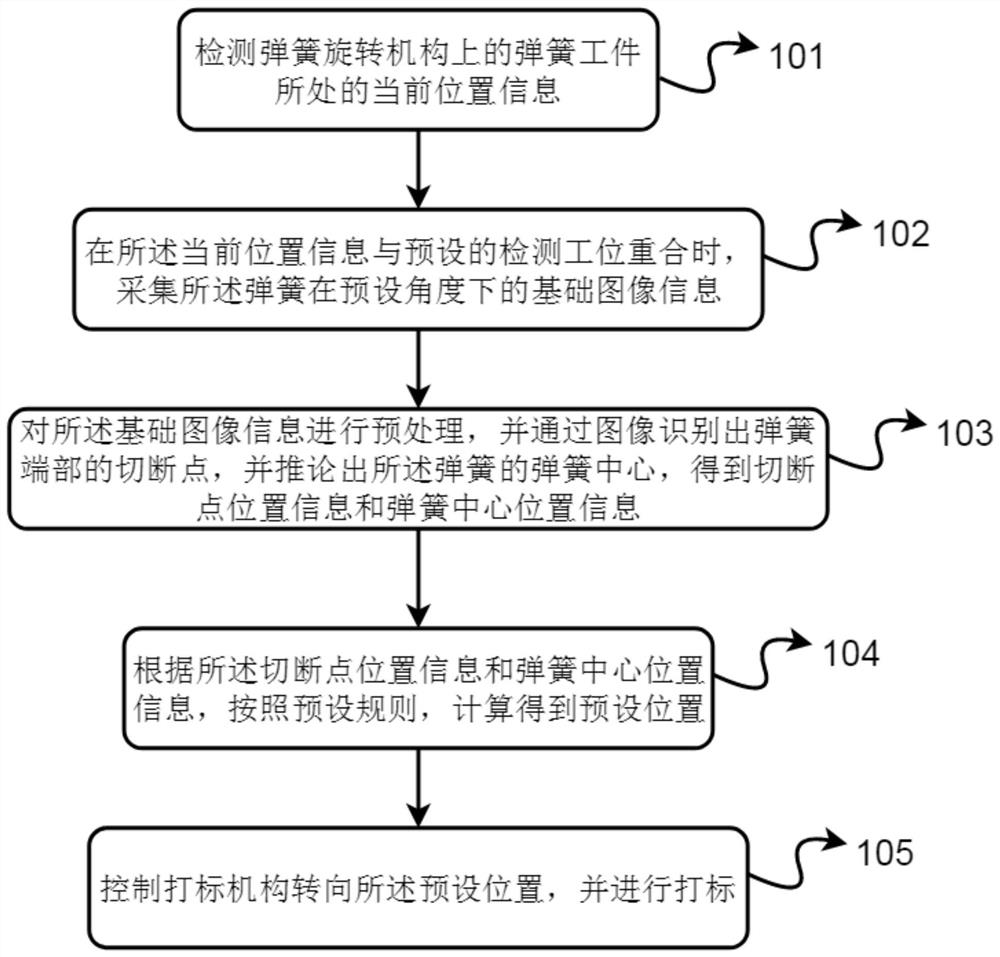

[0043] The first embodiment of the present invention relates to a spring marking method, including: detecting the current position information of the spring workpiece on the spring rotating mechanism; when the current position information coincides with the preset detection station, collecting the The basic image information of the spring workpiece at a preset angle; the basic image information is preprocessed, and the cut-off point at the end of the spring workpiece is recognized through the image, and the spring center of the spring workpiece is calculated to obtain the cut-off point Position information and spring center position information; according to the cut-off point position information and spring center position information, calculate a preset position according to preset rules; control the marking mechanism to turn to the preset position, and perform marking.

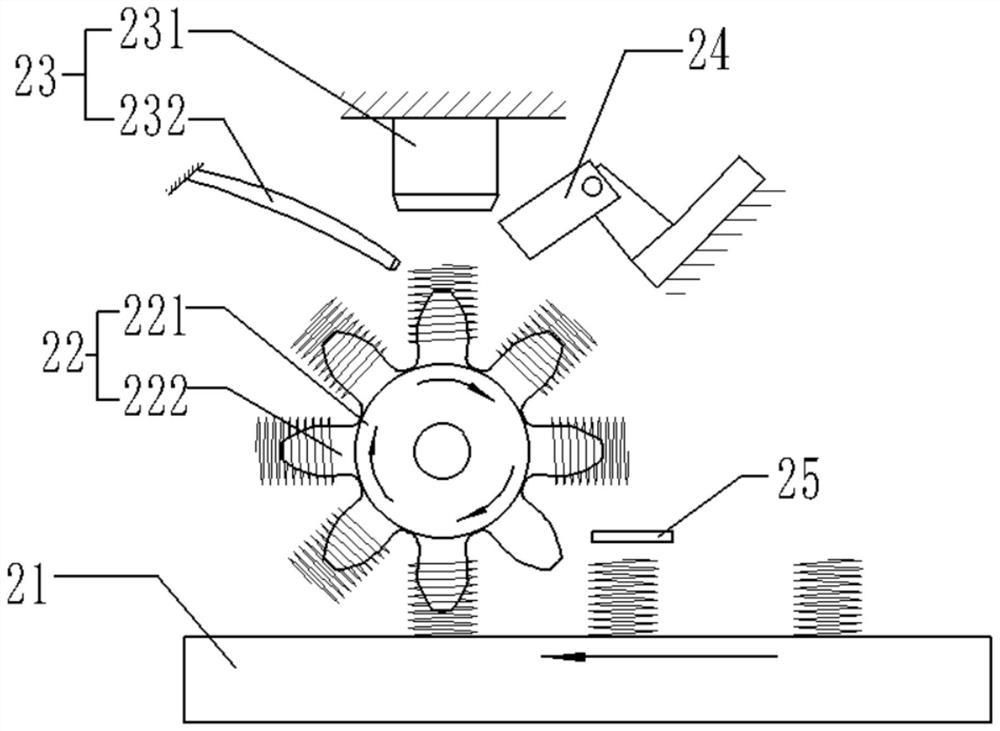

[0044] The spring rotating mechanism is provided with a plurality of fixing parts for clamping the spring ...

no. 2 approach

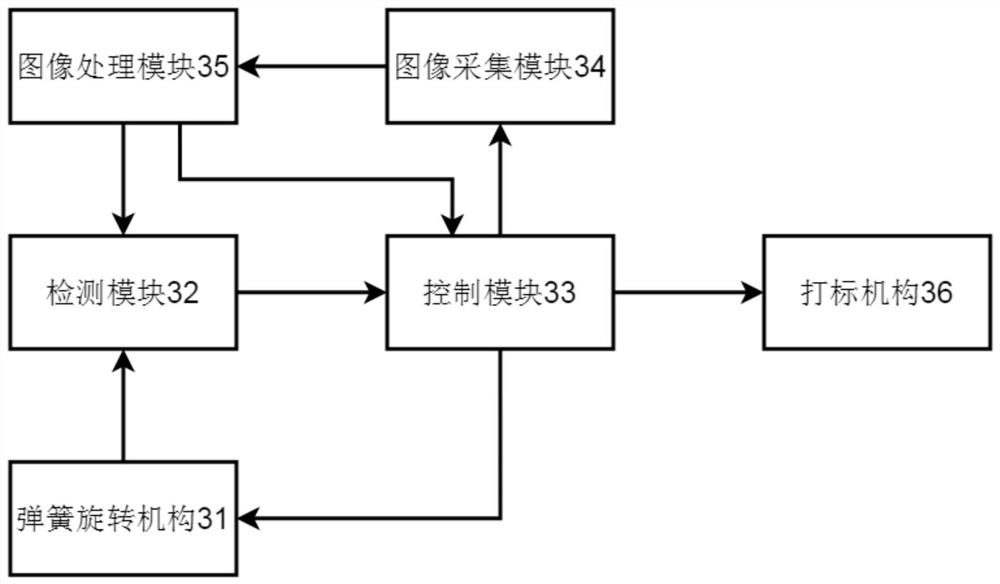

[0079] The second embodiment of the present invention provides a spring marking system, such as image 3 shown, including:

[0080] The spring rotation mechanism 31 is used to limit the spring workpiece and rotate the spring workpiece;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com