Coal crushing and screening machine for coal preparation

A screening machine and crushing mechanism technology, applied in grain processing, etc., can solve problems such as single crushing specifications and incomplete coal screening specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is further detailed in detail by specific embodiments:

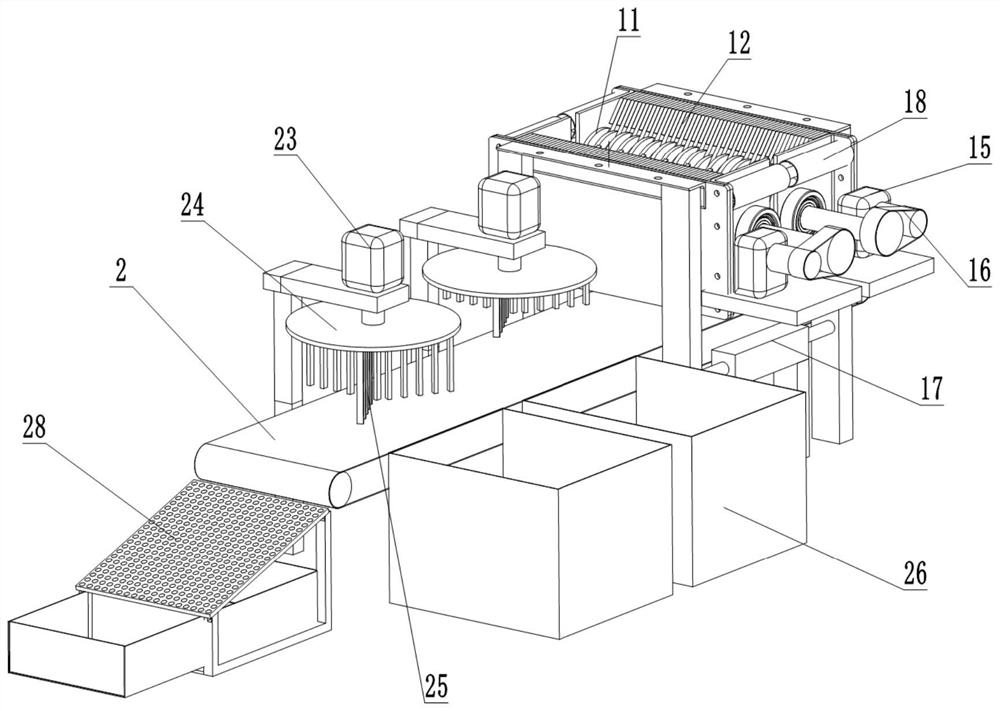

[0034] as Figure 1 As shown, a kind of coal separator for coal block crushing and screening, including coal block crushing mechanism, coal block screening mechanism and control system, coal block crushing mechanism is used to crush coal blocks, and coal block screening mechanism is used to screen the size of the crushed coal blocks.

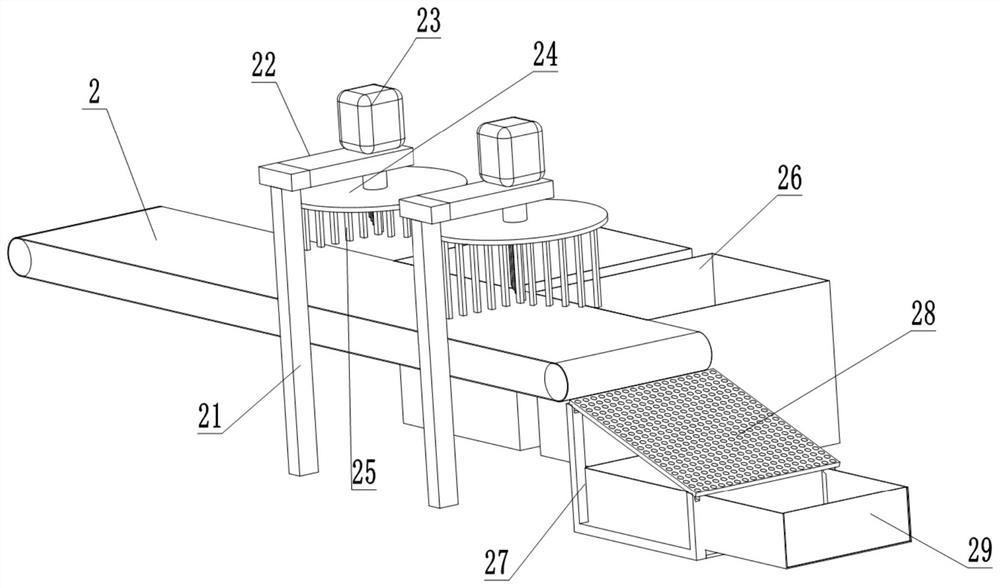

[0035] as Figure 5 、 Figure 6 and Figure 7 As shown, the coal block crushing mechanism includes a mirror set up a first crushing mechanism and a second crushing mechanism, the first crushing mechanism and the upper mirror of the second crushing mechanism are provided with a connection to connect the two, the first crushing mechanism and the lower mirror of the second crushing mechanism are provided with a regulating part 17 to adjust the spacing between the first crushing mechanism and the second shredding mechanism, and the first crushing mechanism and the second shredding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com