Wood waste solid-wood-imitated processing and forming device

A technology of processing and shaping and imitating solid wood, which is applied in the field of imitating solid wood flooring, can solve the problems of time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

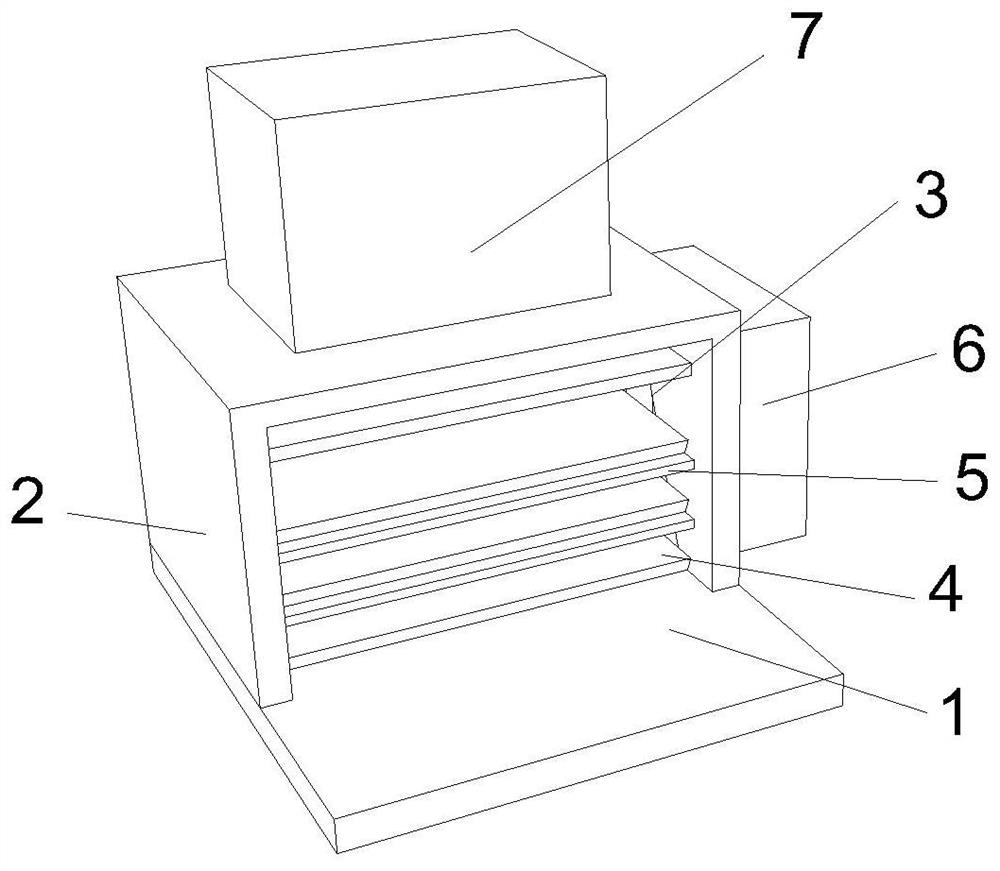

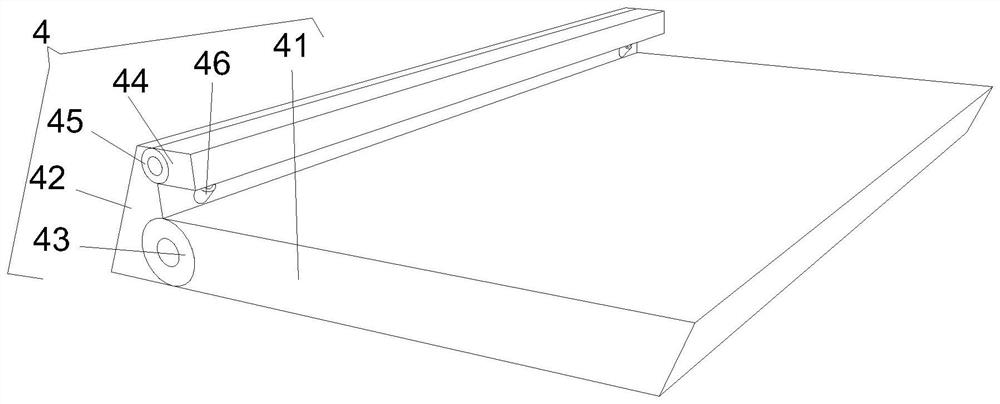

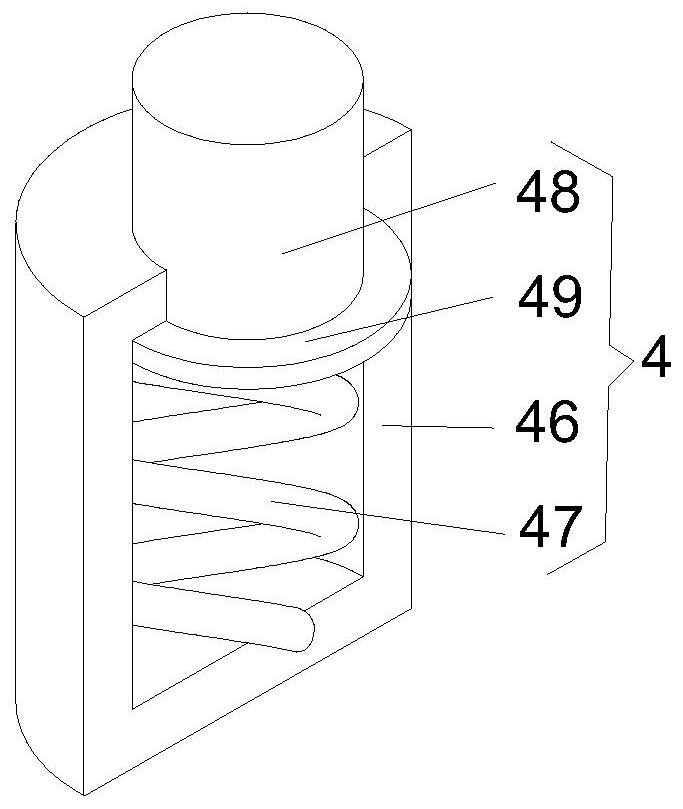

[0034] Example 1: Please refer to Figure 1-Figure 9, a wooden waste imitation solid wood processing and forming device, including a base 1, characterized in that: the top wall of the base 1 is fixed with an outer frame 2, the side wall of the outer frame 2 is hollowed out, and the inner side wall of the outer frame 2 There are ventilation holes 3 on the top, and an extruding device 4 is arranged inside the outer frame 2. The extruding device 4 includes an extruding plate 41. The side wall of the extruding plate 41 is closely attached to the inner side wall of the outer frame 2. The side wall close to the outside of the outer frame 2 on 41 is inclined, and an extrusion block 42 is fixedly installed on the side wall of the extrusion plate 41. The extrusion block 42 is a trapezoidal block, and the exterior of the extrusion plate 41 is provided with a first hinge. 43, the extrusion block 42 is flexibly connected with the extrusion plate 41 through the first hinge 43, the top of t...

Embodiment 2

[0039] Embodiment 2: On the basis of Embodiment 1, please refer to Figure 1-Figure 9 1, the base 1 is provided with a heating device 6 outside, the heating device 6 includes a hot air boiler 61, the hot air boiler 61 is fixedly installed on the outer wall of the outer frame 2, and the output end of the hot air boiler 61 is fixedly installed with Folding tube 62, the folded tube 62 extends to the inside of the outer frame 2 through the air hole 3, the end of the folded tube 62 away from the hot air boiler 61 is fixedly installed with a magnetic tube 63, and the outside of the hot air boiler 61 is provided with a guide block 64. The deflector block 64 is laid on the inner bottom wall of the extruded plate 41. The deflector block 64 is a hexagonal block. The interior of the extruded plate 41 is separated by the deflector block 64 to form multiple channels. The hot air The outside of the boiler 61 is provided with an air inlet 65, and the air inlet 65 is opened on the side wall s...

Embodiment 3

[0041] Embodiment 3: On the basis of Embodiment 1, please refer to Figure 1-Figure 9 1, the top of the base 1 is provided with a processing device 7, the processing device 7 includes a processing frame 71, the inside of the processing frame 71 is provided with a lifting device 72, the lifting device 72 is a disclosed technology, and will not be repeated here. Lifting device 72 is fixedly installed on the inner top wall surface of processing frame 71, and the output end of lifting device 72 is fixedly installed with reinforcing plate 73, and reinforcing plate 73 is the rod of circular truncated shape, and the bottom wall surface of reinforcing plate 73 is fixedly installed with extension bar 74, extends The rod 74 runs through the top wall of the outer frame 2 and extends to the inside of the outer frame 2. A fixing ring 75 is fixedly installed on the side wall of the extension rod 74, and a processing plate 76 is fixedly installed on the bottom wall of the fixing ring 75. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com