Mask convenient to quickly produce and production method thereof

A mask and rapid technology, applied in the field of medical and sanitary products, can solve the problems of unfavorable continuous and rapid production, long time consumption, etc., and achieve the effect of facilitating continuous and rapid production, avoiding safety risks, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

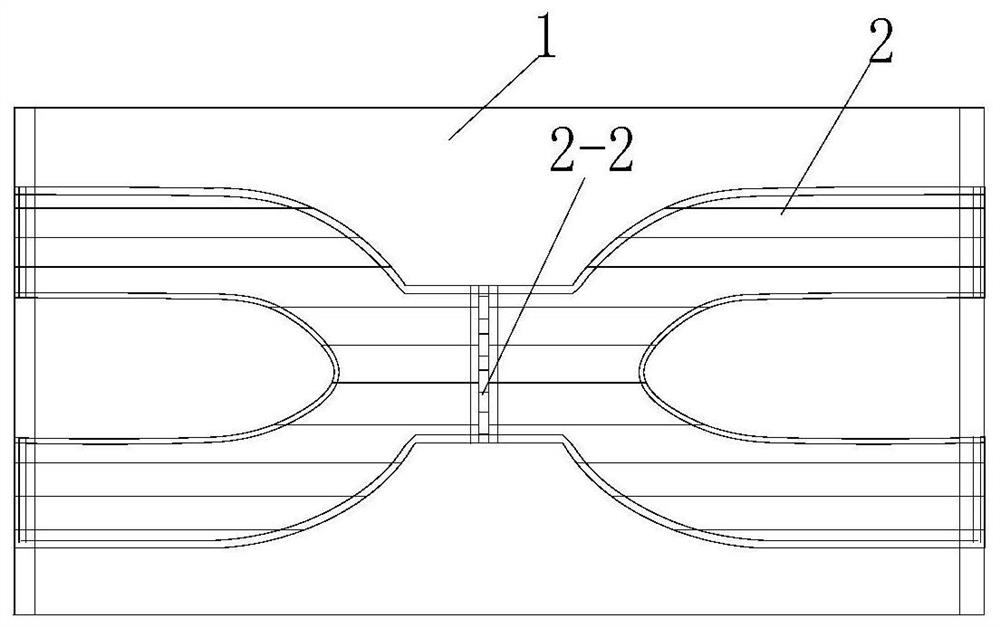

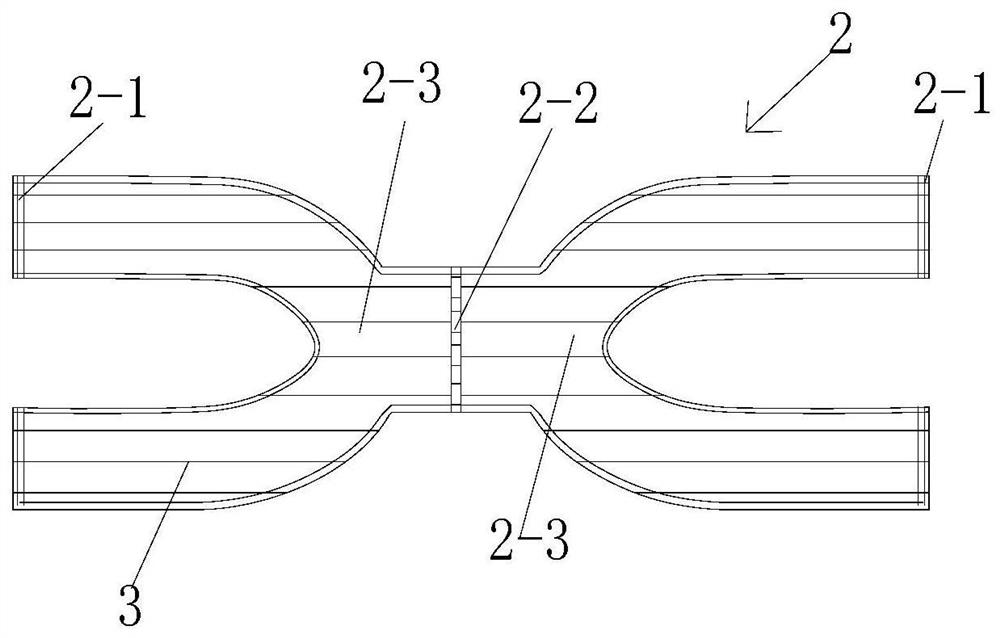

[0030] Such as Figures 2 to 5 Shown, the disposable protective mask of the present embodiment comprises: mask body 1 and the elastic band layer 2 that is located on the inner side of mask body 1, elastic band layer 2 comprises a pair of symmetrical, horizontally tiled U-shaped bodies, each U-shaped body The openings 2-1 are distributed outward and connected to the adjacent edges of the mask body 1, the bottoms 2-3 of the pair of U-shaped bodies are connected to each other, and the joints of the pair of U-shaped bodies are provided with longitudinally distributed tear lines 2 -2; When in use, the user only needs to tear off the two U-shaped bodies along the tear line 2-2, and then the bottoms 2-3 of the pair of U-shaped bodies can be placed on the two ears of the user respectively.

[0031] The elastic belt layer 2 includes: a pair of bonded and laminated non-woven fabrics, a plurality of elastic or elastic spandex filaments or shrinkable films 3 distributed in the pair of non...

Embodiment 2

[0042] On the basis of Embodiment 1, there are the following modifications in this embodiment:

[0043] The elastic belt layer 2 is elastic non-woven fabric.

[0044] The production method of described mask comprises:

[0045] a. Carry out continuous punching one by one according to the length extension direction of the elastic non-woven fabric to obtain a plurality of the above-mentioned elastic belt layers 2 which are continuously connected;

[0046] B, a plurality of above-mentioned elastic belt layers 2 that are connected continuously are delivered to the inner surface of a plurality of mouth mask bodies 1 that are connected continuously and aligned, and the openings 2-1 of a pair of U-shaped bodies in each elastic belt layer 2 are passed through ultrasonic waves. Welding is connected on the corresponding edge of corresponding mask body 1, obtains a plurality of masks that are connected continuously;

[0047] c. Cut off and pack the continuous connected masks respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com