Cabin structure of deep-sea culture ship

A cabin and deep-sea technology, applied in the field of deep-sea aquaculture vessels, can solve the problems of not specifically considering the breeding of fish, the difficulty of forming a flow field in aquaculture water, and being unsuitable for fish growth, achieving weight reduction, low cost, and convenient layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

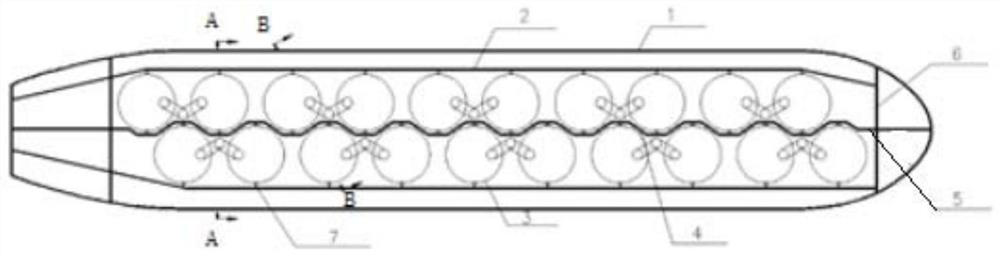

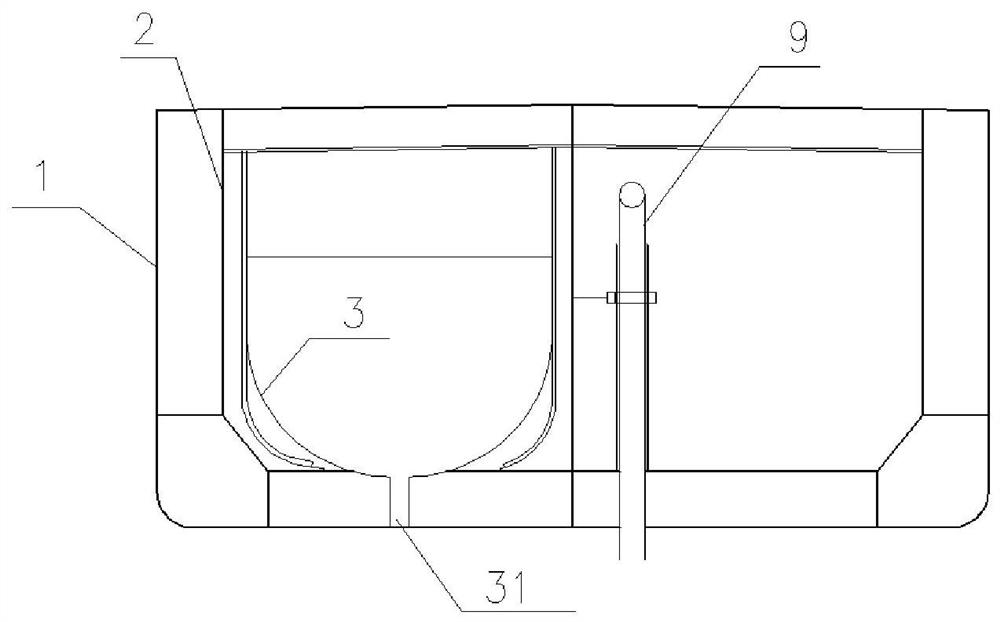

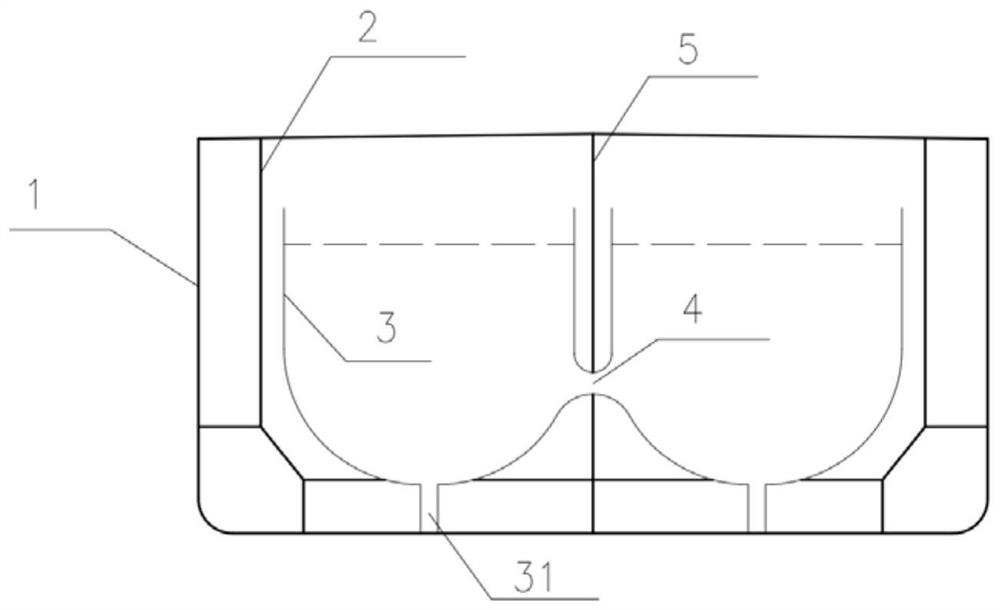

[0030] The cabin structure of the deep-sea breeding ship proposed by the present invention adopts a longitudinal skeleton type and a double shell structure, wherein the longitudinal bulkhead in the ship is a trough bulkhead 5 adapted to the breeding cabin, and the layout of the breeding ship is as follows: figure 1 shown. The cabin structure includes an outer shell 1 of a breeding ship, an inner shell 2 of the breeding ship, a breeding cabin 3 , a channel 4 , a grooved bulkhead 5 , a transverse bulkhead 6 , and bulkhead reinforcement ribs 7 . The two ends of the inner hull 2 of the breeding ship are welded with transverse bulkheads 6 and longitudinal bulkheads, and there is a channel 4 in the middle. There are multiple groups of breeding cabins 3 arranged on both sides of the channel 4, and bulkheads are connected between the breeding cabins 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com