Damping device for sediment stirring equipment for concrete production

A technology of mixing equipment and shock absorbing device, which is applied in the direction of cement mixing device, clay preparation device, mechanical equipment, etc. It can solve the problems that the shock absorbing device cannot dissipate the vibration energy, and the shock absorbing device cannot play the role of shock absorption and compression resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

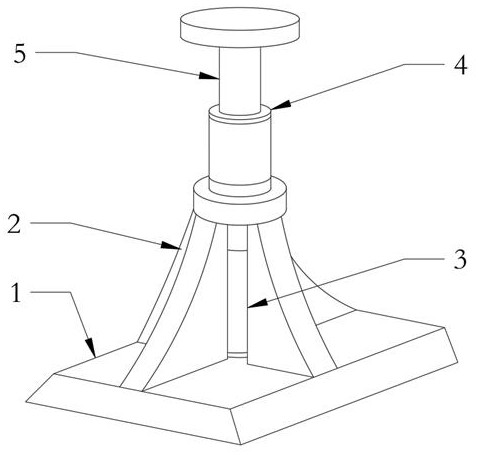

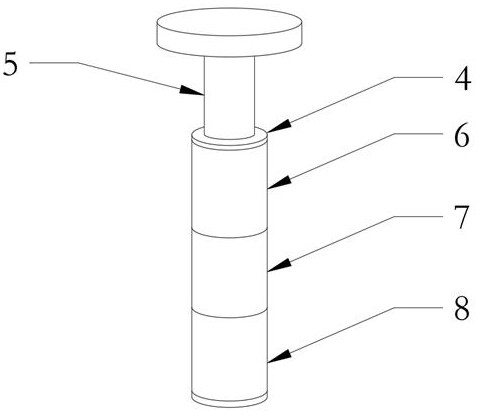

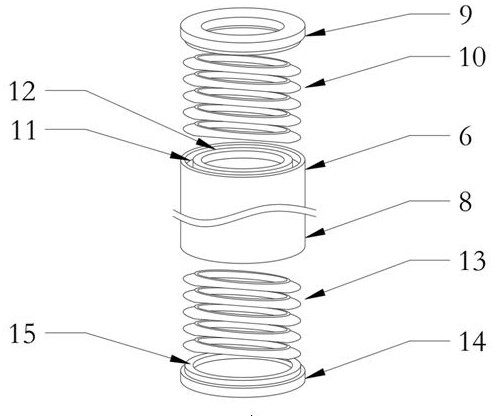

[0022] see Figure 1-5 , the present invention provides a technical solution: a shock absorbing device for sand mixing equipment used in concrete production, including a foot plate 1, a prism plate 2 is fixed in the middle of the upper surface of the foot plate 1, and the middle of the prism plate 2 is There is a rod cavity 3 in the position, and a spring column 4 is inserted in the middle position of the prism plate 2. The spring column 4 is inserted and installed with the foot plate 1 through the prism plate 2 and the rod cavity 3. The overall shape of the foot plate 1 is Ladder type. The inner middle position of the spring column 4 is equipped with a top plate rod 5, the outer surface of the spring column 4 is provided with a first-order bullet column 6 near the upper part, and the middle part of the spring column 4 is provided with a second-order bullet column 7, and the outer surface of the spring column 4 is close to the bottom. A third-stage bullet 8 is provided, and t...

Embodiment 2

[0027] Such as Figure 4-5 As shown, the present invention provides a technical solution: a shock-absorbing device for sand mixing equipment used in concrete production, the inner side of the second-stage bollard 7 and the outer surface of the inner wall rod 12 is sleeved with a second-stage spring 17, The middle position of the left end surface of the top plate rod 5 is fixed with a secondary rod 18, and the lower surface of the secondary rod 18 is fixed with a bottom ring 19, and the inner wall rod 12 is fixedly installed with the second-stage bullet post 7 through the boundary wall 16, and the second-stage spring 17 is positioned and installed by inner wall rod 12 and second-order bullet post 7, and the diameter of secondary rod 18 is less than the diameter of top disc rod 5, and the diameter of bottom ring 19 is equal to the diameter of top disc rod 5. The middle position of the lower surface of the bottom ring 19 is fixed with an inner rod 20, and the outer surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com