Tool unclamping device using ball screw for transmission

A technology of ball screw and screw rod, which is applied in the field of knife cutter, and can solve the problems of crawling, large exhaust sound of solenoid valve, noise pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in combination with specific embodiments.

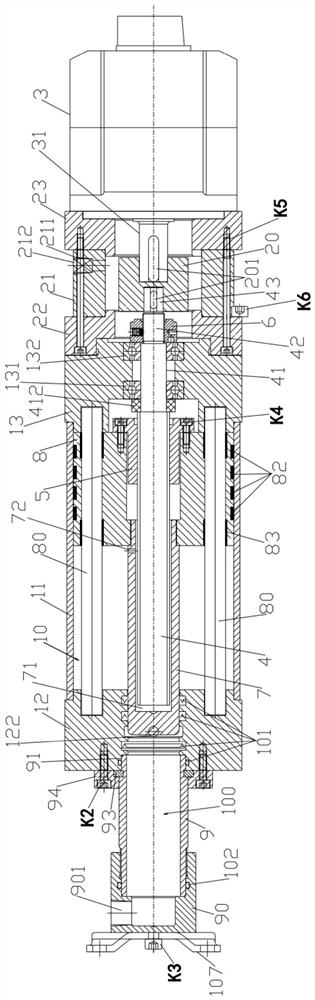

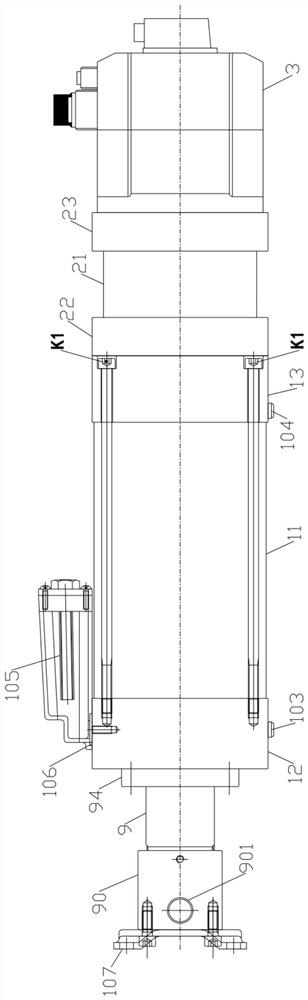

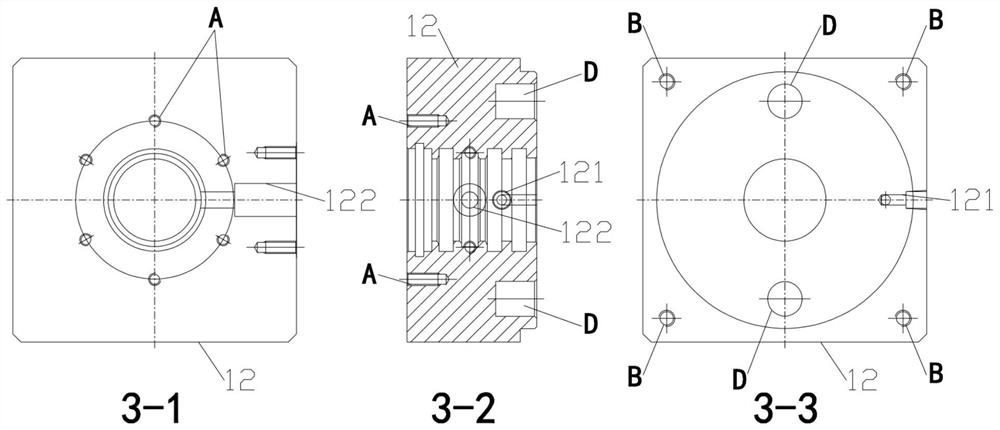

[0034] Such as figure 1 and 2As shown, a knife driver using a ball screw for transmission according to an embodiment of the present invention includes a cylinder body 11 and a piston rod 7, and the two ends of the cylinder body 11 are respectively fixed with a front cover 12 and a rear cover 13 To form cavity 10, screw mandrel 4 is installed in cylinder block 11, and the processing of screw mandrel 4 has the helix that has continuous and same pitch, and screw mandrel nut 5 is provided with internal thread and is sleeved on the screw mandrel 4, and screw mandrel 4 One end of the piston rod 7 is connected with a driving mechanism 3 that drives the screw rod 4 to rotate. When the screw rod 4 rotates, the screw nut 5 moves back and forth relative to the screw rod 4, and the right end of the piston rod 7 is provided with a housing chamber for receiving the other end of the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com