Assembly process of oil-free vacuum pump

An oil-free vacuum pump and assembly process technology, which is applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the installation efficiency of oil-free vacuum pumps, the fixed structure of the cylinder end surface and the fixed deviation of the cylinder, and the easy installation position of the rotor. Problems such as offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

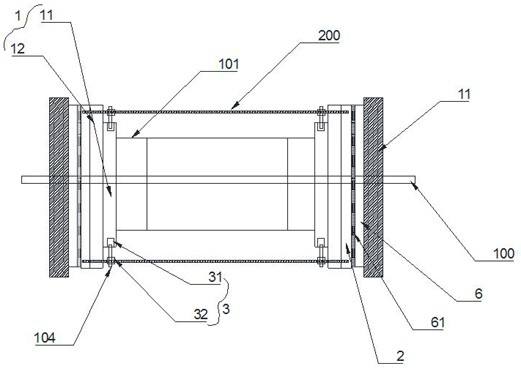

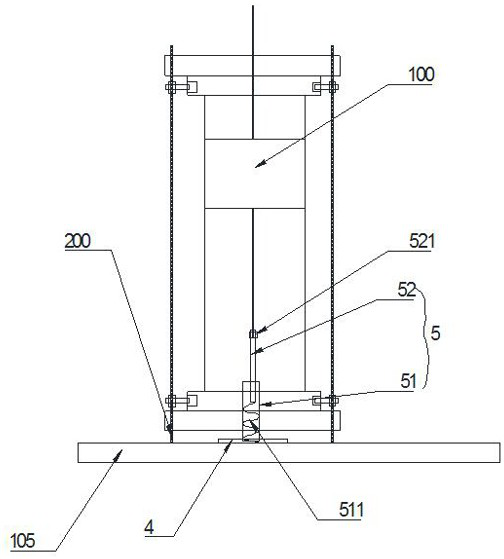

[0027] Such as Figure 1 to Figure 2 A specific embodiment of the present invention specifically includes the following steps:

[0028] S1. The openings at both ends of the cylinder body 101 are fitted with outwardly protruding annular step surfaces 1, and several clamping rods 200 are connected to the two annular step surfaces 1, and several clamping rods 200 surround the outside of the cylinder body 101 in a circular shape. And it is arranged coaxially with the cylinder body 101, and the locking rods 200 all extend outside the annular stepped surface 1;

[0029] S2. Using several clamping rods 200 as suspended force points, knock the rotor 100 evenly inside the cylinder body 101;

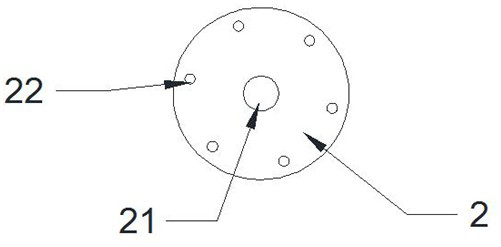

[0030] S3, passing the sulfuric acid paper 2 through the rotor 100 and the clamping rod 200 in sequence and attaching them to the openings at both ends of the cylinder body 101;

[0031] S4. The front cover 102 and the rear cover 103 are pre-positioned against the sulfuric acid paper 2 and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com