Laser reflector seat capable of eliminating resonance effect generated by machine motion

A mirror seat and resonance effect technology, applied in optics, instruments, optical components, etc., can solve problems such as optical path offset, optical path focus position, focus point offset, ghosting, vibration, etc., to eliminate optical path swing offset, ensure The effect of focus stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

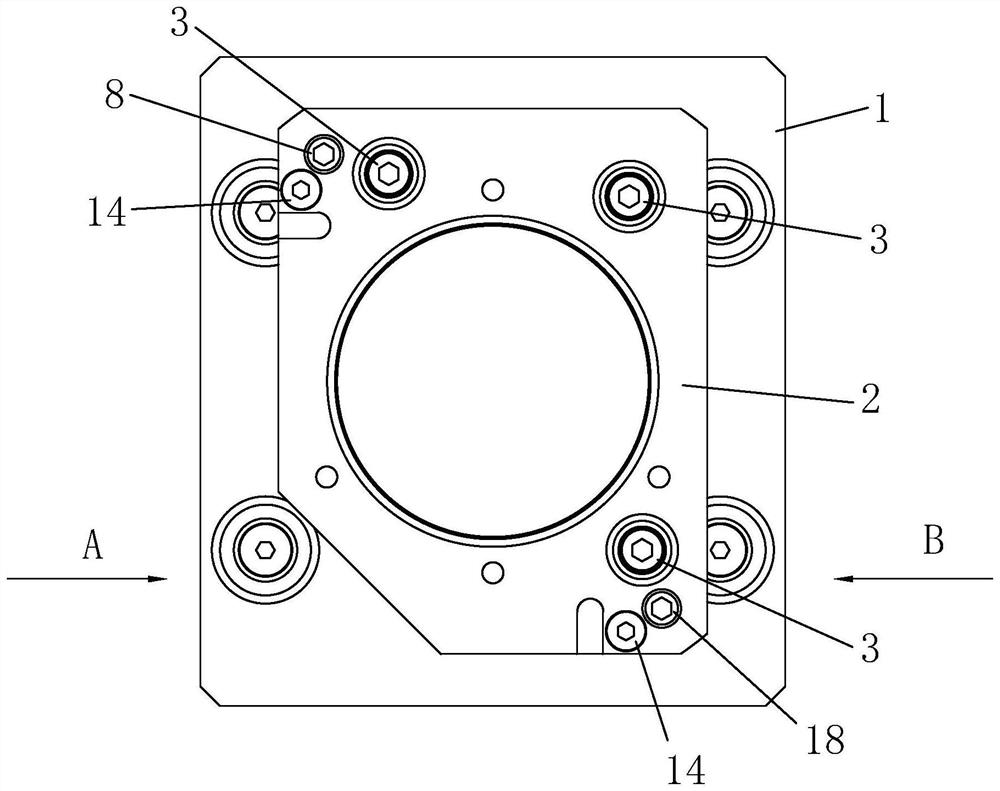

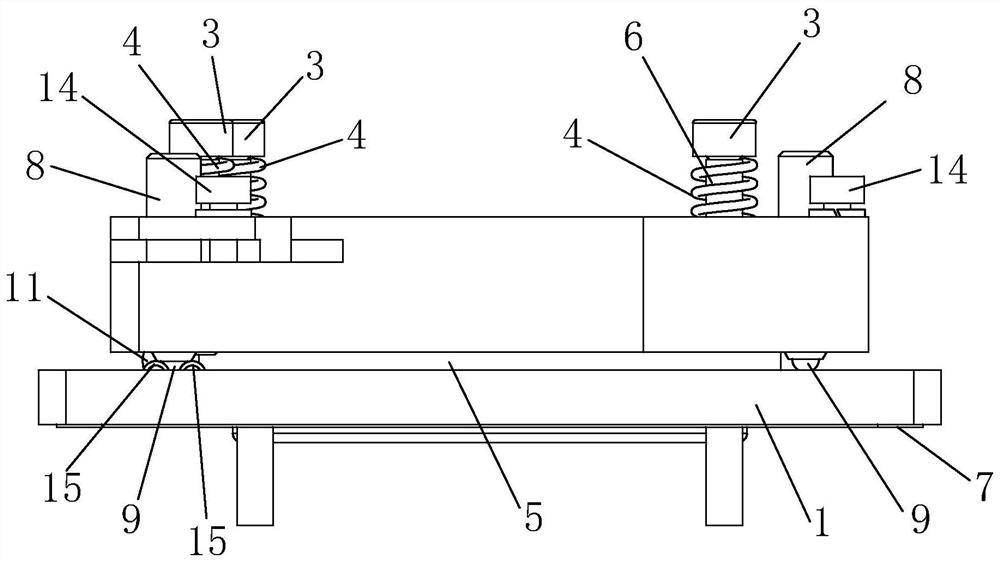

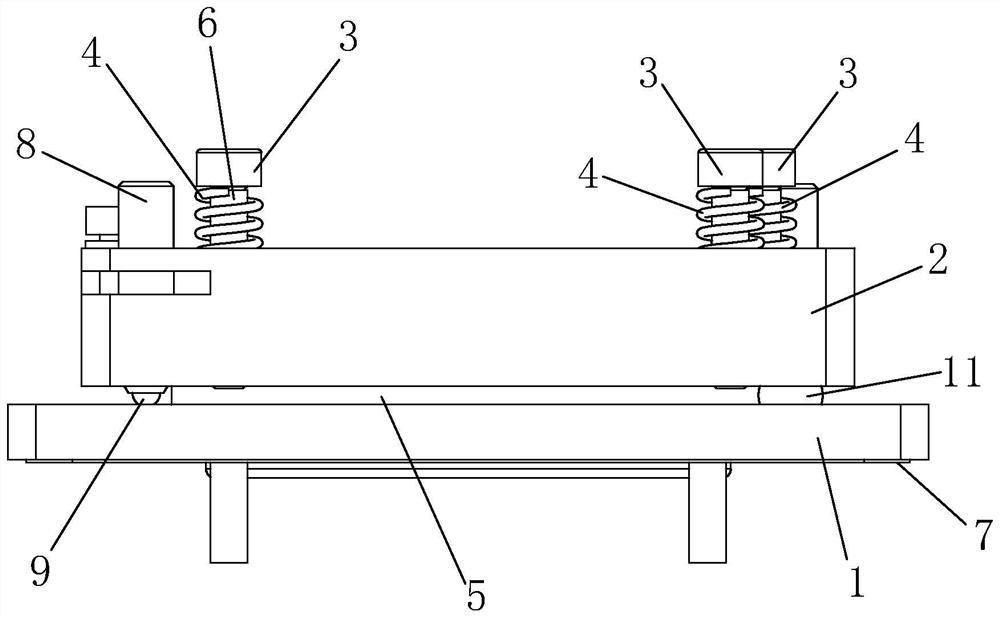

[0023] Such as Figure 1 to Figure 4 Shown, for the present invention can eliminate the laser reflector base of machine movement to produce resonance effect, comprise base plate 1, reflector base 2, fixing bolt 3 and spring 4, the afterbody of fixing bolt 3 passes through reflector base 2 and connects with base plate 1 Threaded connection, the spring 4 is sleeved on the fixing bolt 3, and the spring 4 is arranged between the head of the fixing bolt 3 and the reflector seat 2. Through the setting of the spring 4 and the fixing bolt 3, the connection between the bottom plate 1 and the reflector seat 2 is realized. At the same time, this structure is used to connect, and the elastic force of the compression spring 4 and the reaction of the screw tension can be used to directly eliminate the phenomenon that occurs when the machine is moving. The optical path swing and offset phenomenon caused by the transmission vibration of the advanced mechanism ensures the final focus stability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com