Device and method for detecting seed metering performance of air suction seed metering device

A detection device and detection method technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as operational performance degradation, errors, and difficulty in satisfying the detection of seed metering devices, so as to improve detection accuracy and improve seeding The effect of level and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

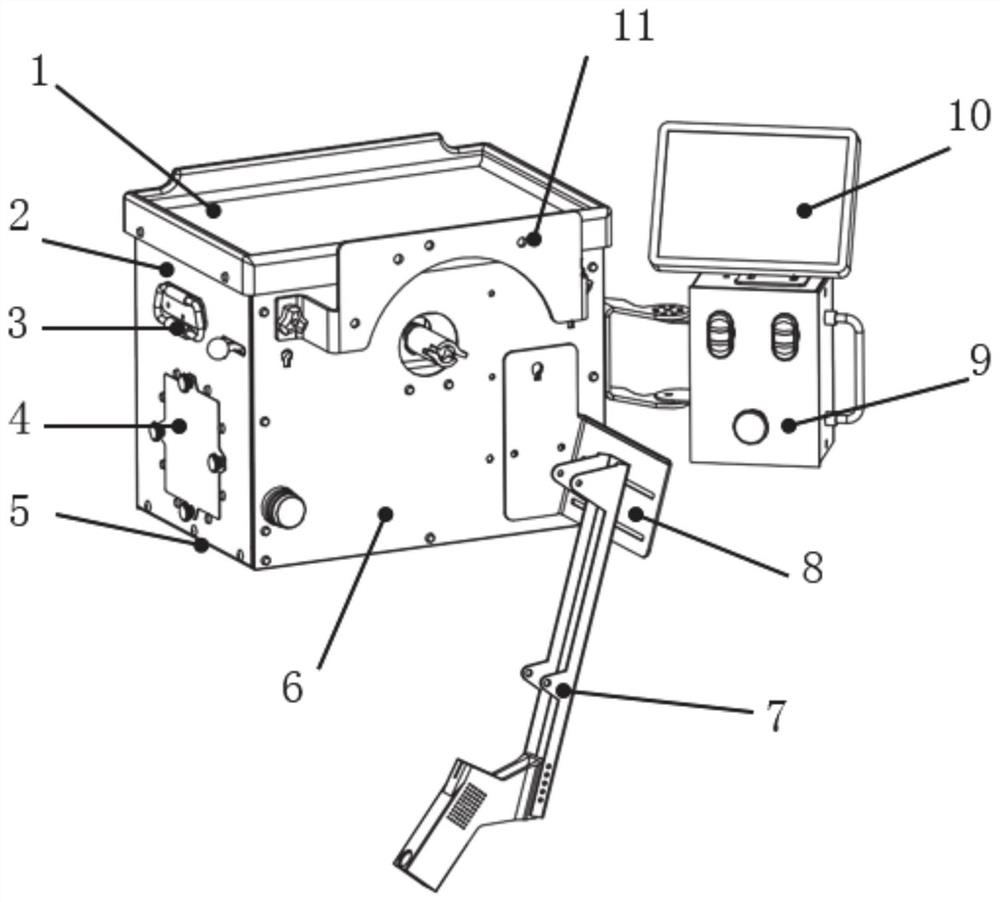

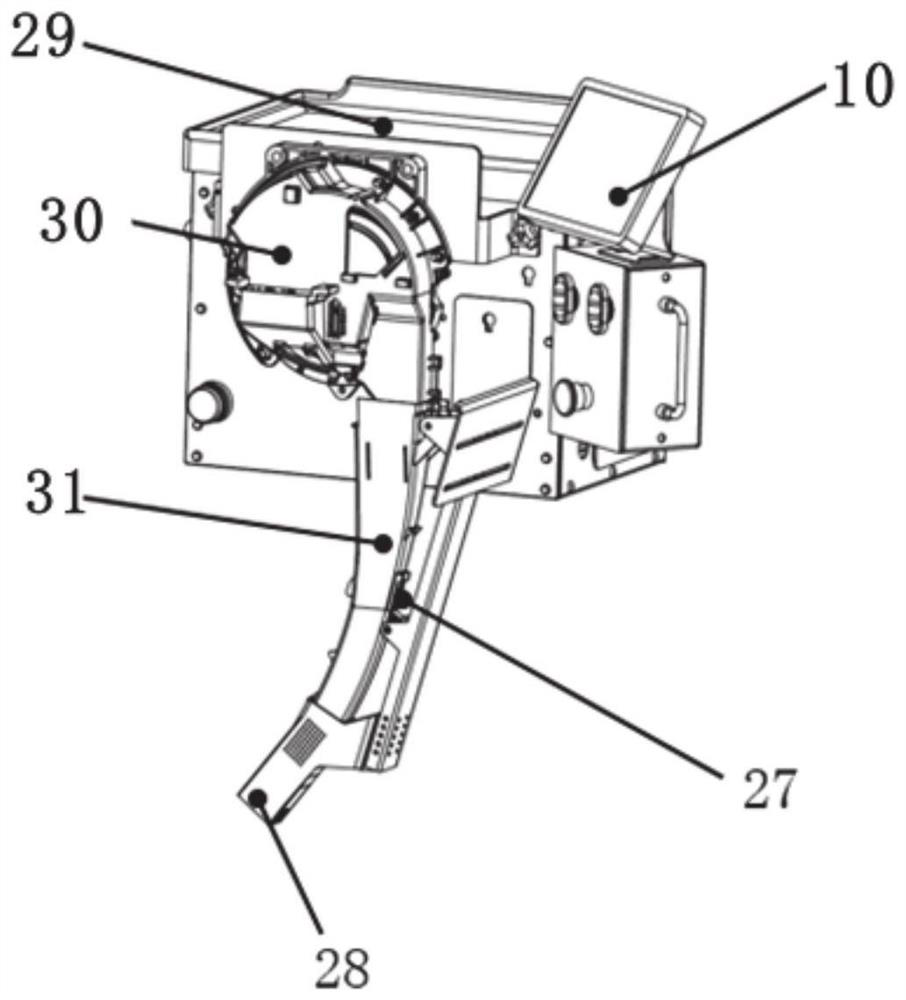

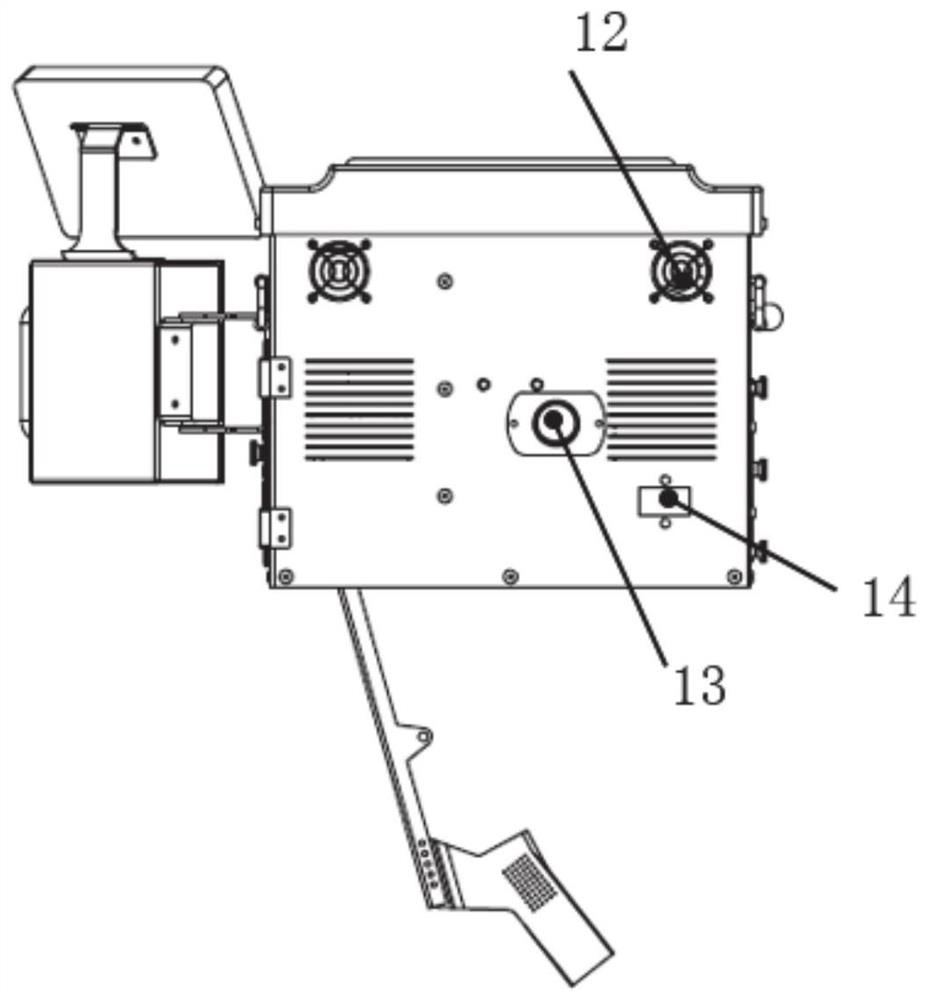

[0037] In a typical implementation of the present disclosure, such as Figure 1-Figure 10 As shown, a device for testing the seeding performance of an air suction seed metering device is proposed.

[0038] It mainly includes a housing, a driving mechanism installed on the housing, a sensor detection unit, a controller and a touch screen display module.

[0039] Wherein the housing includes an upper housing 1, an outer housing 2, and a bottom housing which are sequentially connected. The tooling frame of the seed meter 30 is the first bracket, and the tooling frame of the seed introduction tube 31 is the second bracket. Both are installed on the housing. The seed metering device 30 to be detected is fixed by connecting the seed metering device 30 tooling frame, and the seed introducing pipe 31 matched with the seed metering device 30 to be detected is fixed by connecting the seed metering device 31 tooling frame;

[0040] The sensor detection unit includes a first sensor 27, a...

Embodiment 2

[0063] In another typical implementation of the present disclosure, such as Figure 1-Figure 10 As shown, a method for detecting the seeding performance of an air suction seed metering device is proposed, using the device for detecting the seeding performance of an air suction seed metering device as described in Example 1.

[0064] Install the seed guide pipe 31 at the outlet of the seed meter 30, adjust the parameters of the seed meter 30 and drive the seed meter 30 to run;

[0065] Use the sensor to detect the seed falling at the outlet of the seed meter 30 and the outlet of the seed guide tube 31, and obtain the seeding interval and number respectively and send them to the controller;

[0066] The controller calculates the distribution of seeds output by the seed metering device 30 and the distribution of seeds output by the seed guide tube 31 according to the acquired data, and compares them with the set indicators to analyze the performance of the seed metering device 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com