Automatic vehicle body measuring device based on visual tracking and measuring method thereof

A technology of visual tracking and measuring devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high cost, low efficiency, poor measurement accuracy, etc., to avoid the influence of measurement accuracy, low cost, low automation and precision measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

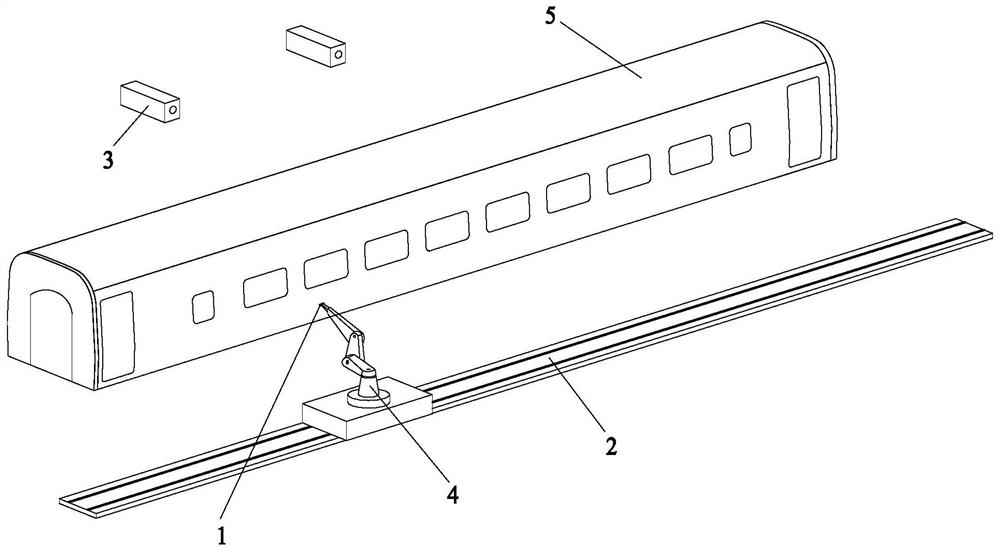

[0018] Such as figure 1 As shown, the vehicle body automatic measurement device based on vision tracking of the present invention includes: a high-precision binocular vision measurement system 1, a guide rail movement control system 2, a photogrammetric camera tracking system 3 and a robot 4, and the robot 4 can use an ABB robot IRB 6700- 150 / 3.2; the high-precision binocular vision measurement system is used to collect high-precision point clouds and high-resolution image data within the range of 600mm×800mm on the car body 5; the guide rail movement control system 2 is located on the side of the car body 5 , which is used to accurately control the stroke of the robot 4 along the longitudinal direction of the car body 5; the robot 4 is installed on the guide rail of the guide rail movement control system 2, and the robot 4 is used to clamp th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com