A layered liquid pipetting device and method of use thereof

A liquid pipetting device and liquid pipetting technology, applied in chemical instruments and methods, measuring tubes/pipettes, laboratory containers, etc., can solve the problems of reducing the accuracy of pipetting, reducing the purity of pipetting liquids, etc., and achieve improved The effect of pipetting accuracy, reducing the requirements for experience and quality, and reducing the risk of absorbing the lower layer of liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

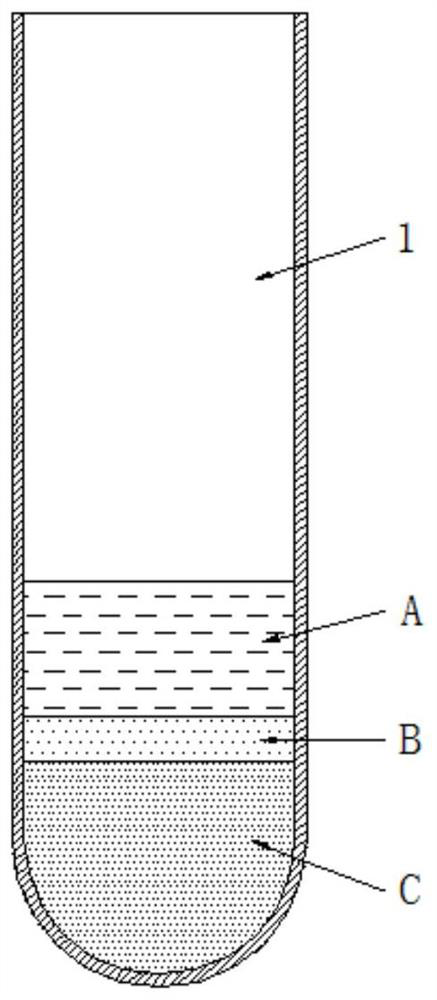

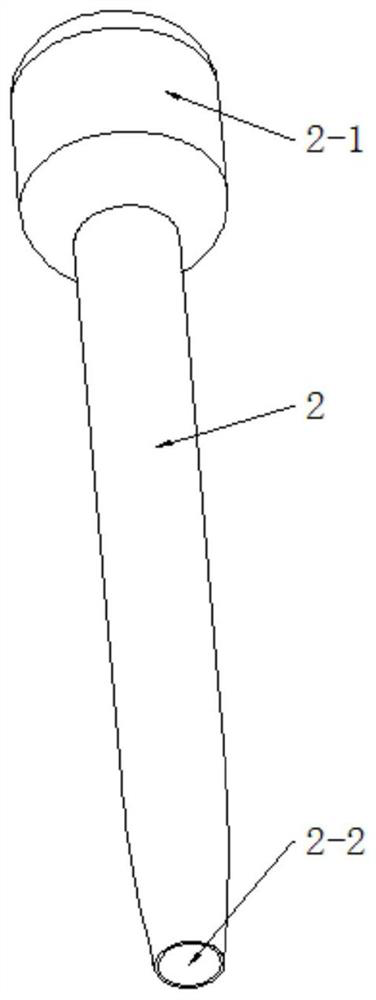

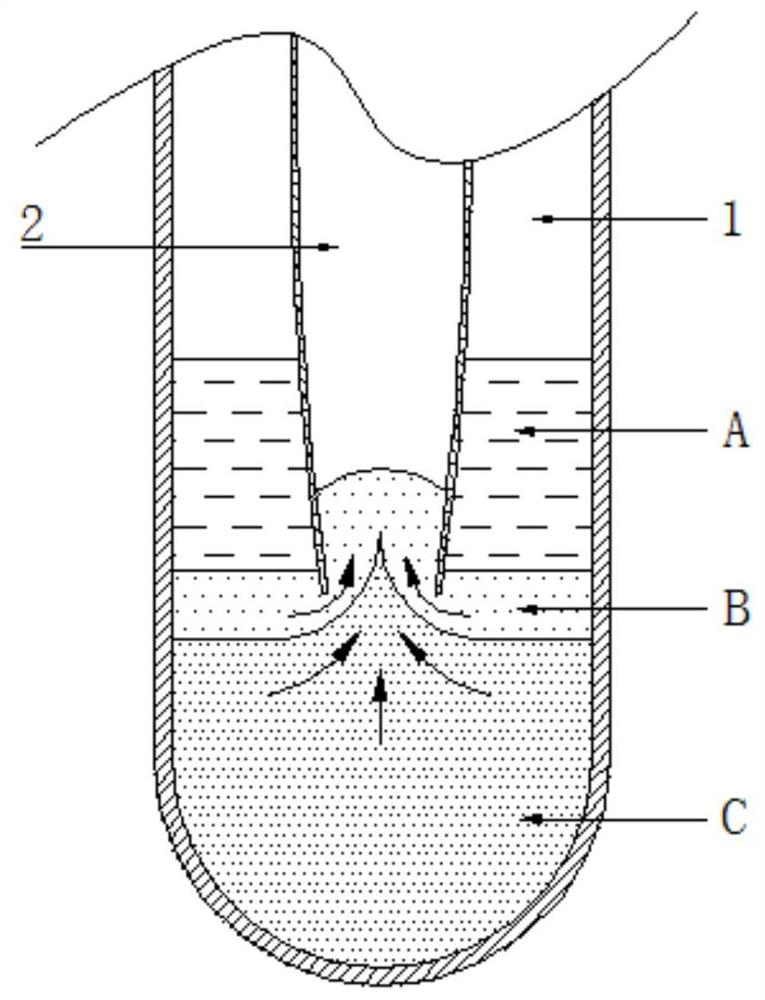

[0070] A layered liquid pipetting device consisting of pipette 2 and pipette holder.

[0071] as Figure 4 As shown, the upper end of the pipette 2 is provided with a squeeze pack 2-1, and the lower end side wall of the pipette 2 is provided with a suction port 2-2. as Figure 5 As shown, when using a pipette 2 to aspirate liquid, first squeeze squeeze pack 2-1, so that the air inside the pipette 2 is discharged from the suction port 2-2; and then release the squeeze of the squeeze pack 2-1, in the process of loosening the squeeze package 2-1, the inner cavity of pipette 2 can be sucked into the pipette 2 from the suction port 2-2 because it is a negative pressure state.

[0072] as Figure 6-8 As shown, the pipette includes a pipette 3, a pipetting clip 5, a pipetting drive, a lift, a container disc 6, a container holder 7, a container drive.

[0073] as Figure 9 As shown, pipette 3 is provided with pipette placement wells 3-1 and pipette placement wells 3-1 for placing pipettes 2. ...

Embodiment 2

[0093] Example 2 is based on Example 1, the structure of the pipette 2 is improved.

[0094] asFigure 10-12 As shown, in the present embodiment, the lower end of the pipette 2 employs a flat tube 2-3, the flat tube 2-3 has two side walls, respectively, denoted as side wall a and side wall b, at least one side wall is provided with the aspiration port 2-2. as Figure 10 As shown, only the side wall a is provided with a suction port 2-2; as shown Figure 11 and Figure 12 As shown, when both sidewall a and sidewall b are provided with aspiration ports 2-2, the aspirate ports 2-2 on sidewall a are disposed on the posterior side of sidewall a, and the aspiration port 2-2 on sidewall b is disposed in front of side wall b, so that the aspiration port 2-2 on side wall a and the suction port 2-2 on side wall b are set away from each other.

[0095] When only the side wall a is provided with a suction port 2-2, the container needs to be rotated 360° to complete the pipetting.

[0096] When bo...

Embodiment 3

[0100] Example 3 of the present embodiment provides another pipette structure based on Example 2.

[0101] as Figure 13 or Figure 14 As shown, in the present embodiment, the lower end of the flat tube 2-3 is open 2-3-1, the open 2-3-1 is communicated with the aspiration port 2-2.

[0102] By opening the lower end of the flat tube 2-3 to 2-3-1, it is convenient to open the suction port 2-2, making the processing simple and conducive to improving the processing efficiency.

[0103] In the present embodiment, although the lower end of the flat tube 2-3 is open 2-3-1, but because it is a flat tube 2-3, so the lower end of the flat tube 2-3 open 2-3-1 is narrow, when removing the B layer liquid, can reduce the removal of the C layer liquid, compared with the background technique, or can reduce the removal of the C layer liquid, is conducive to improving the removal accuracy, and then conducive to improving the experimental accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com