Rotary internal combustion engine and operating method thereof

A technology of internal combustion engine and rotor, which is applied to the rotor type internal combustion engine and its working field, can solve the problems of idling possibility and low efficiency, and achieve the effect of simple technical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In the following detailed description of embodiments of the invention, numerous implementation details are set forth in order to provide a thorough understanding of the invention. However, it will be apparent to one skilled in the art that the present invention may be used with or without these implementation details. In other instances, well-known techniques, procedures, and components have not been described in detail so as not to obscure the details of the present invention.

[0065] Furthermore, it is apparent from the foregoing description that the invention is not limited to the described embodiments. Many possible modifications, changes, transformations and substitutions, while remaining true to the essence and form of the invention, will be apparent to those skilled in the art.

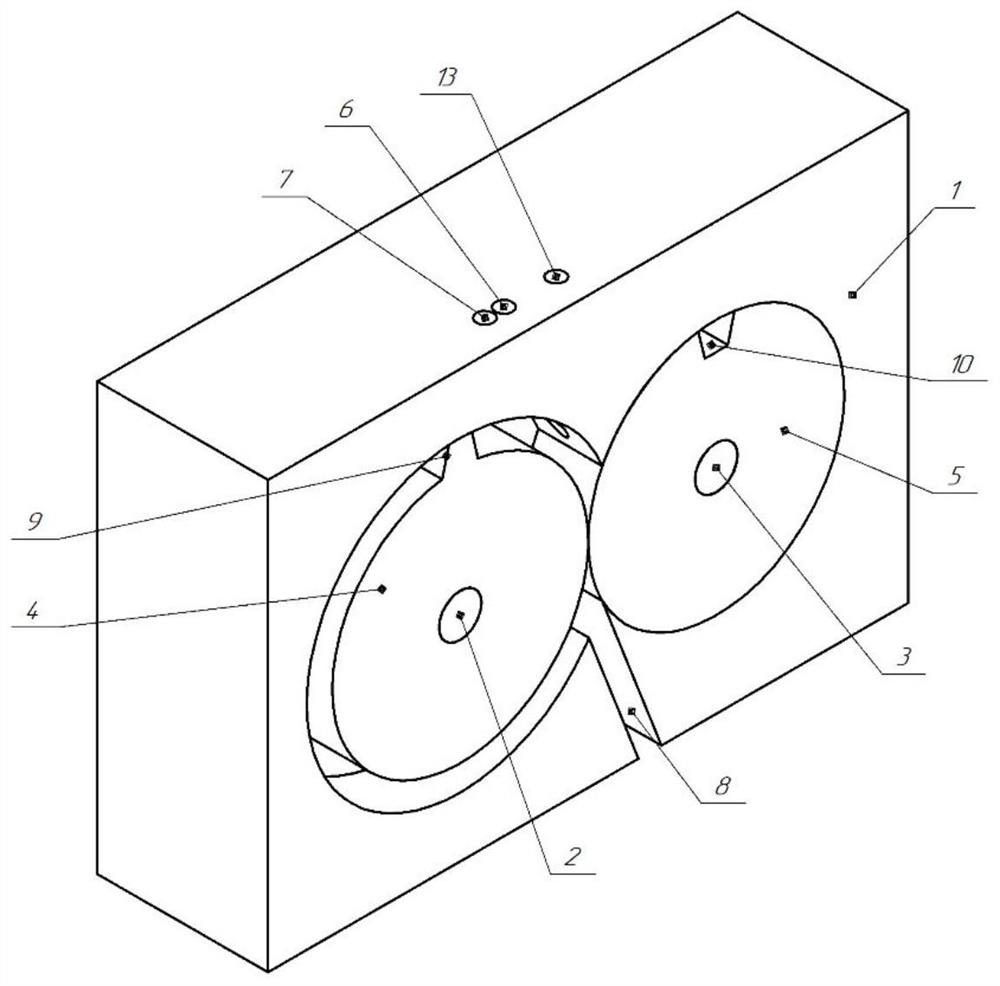

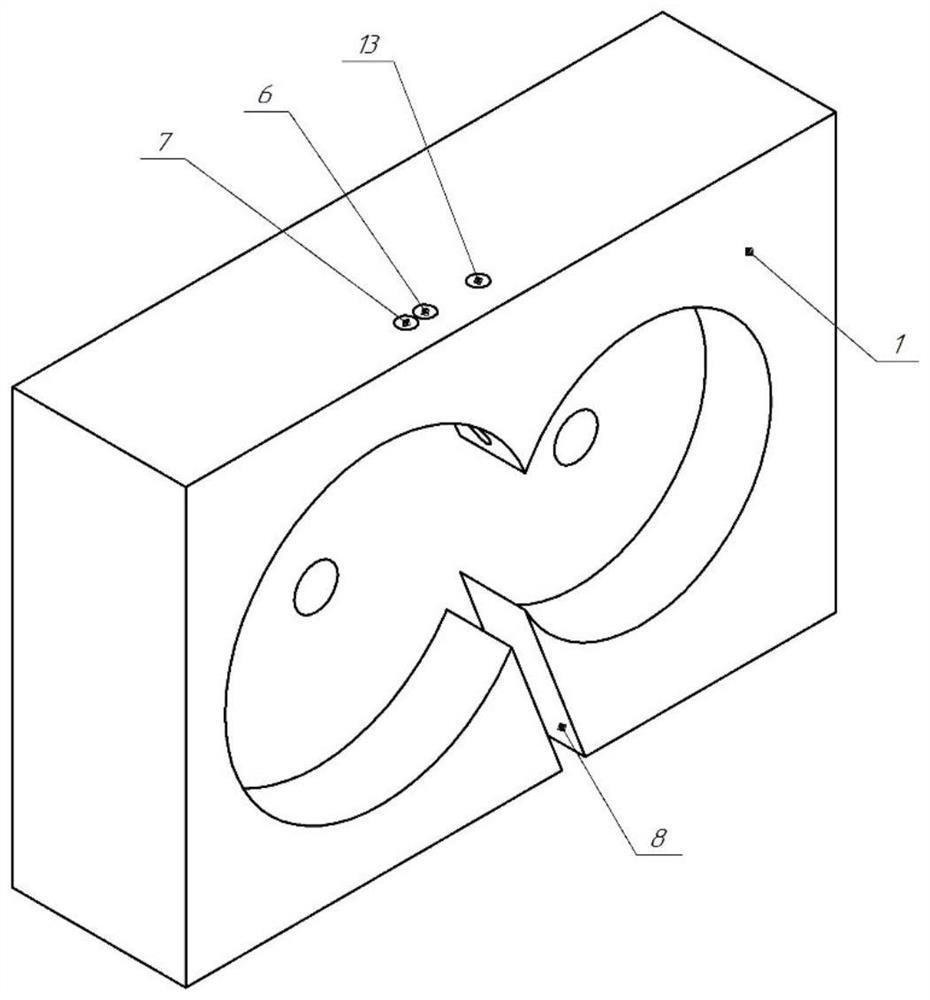

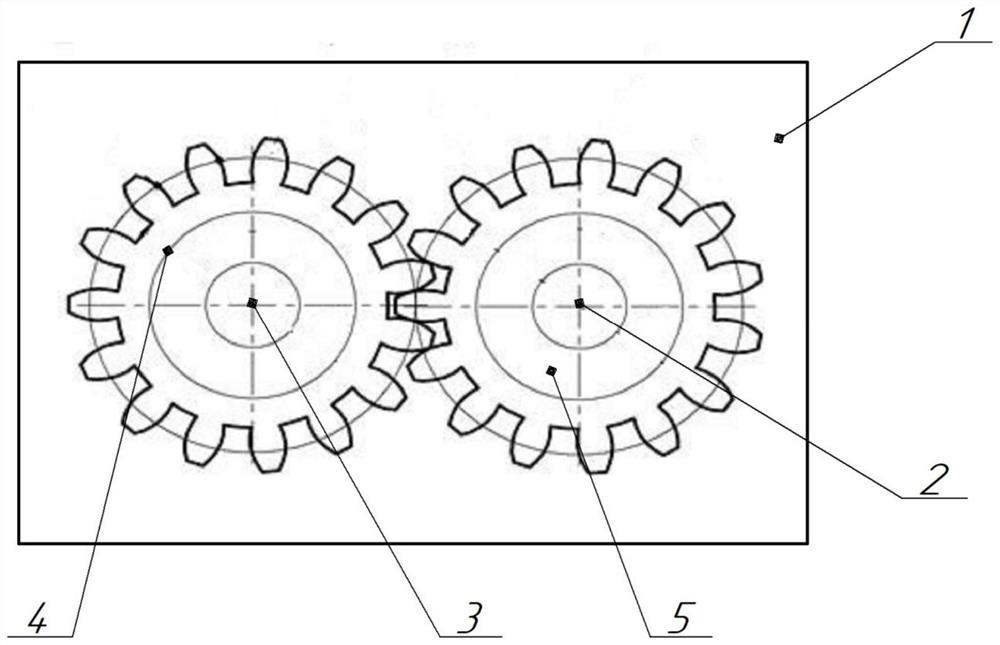

[0066] The casing 1 has a cylindrical cavity for accommodating the active rotor 2 and the passive rotor 3 without gaps.

[0067] The housing 1 can be composed of various structural ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com