High-precision motor core

A high-precision, movement technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as poor matching accuracy and mechanical damage, and achieve the effect of ensuring high-precision matching, reducing impact, and avoiding abnormal contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

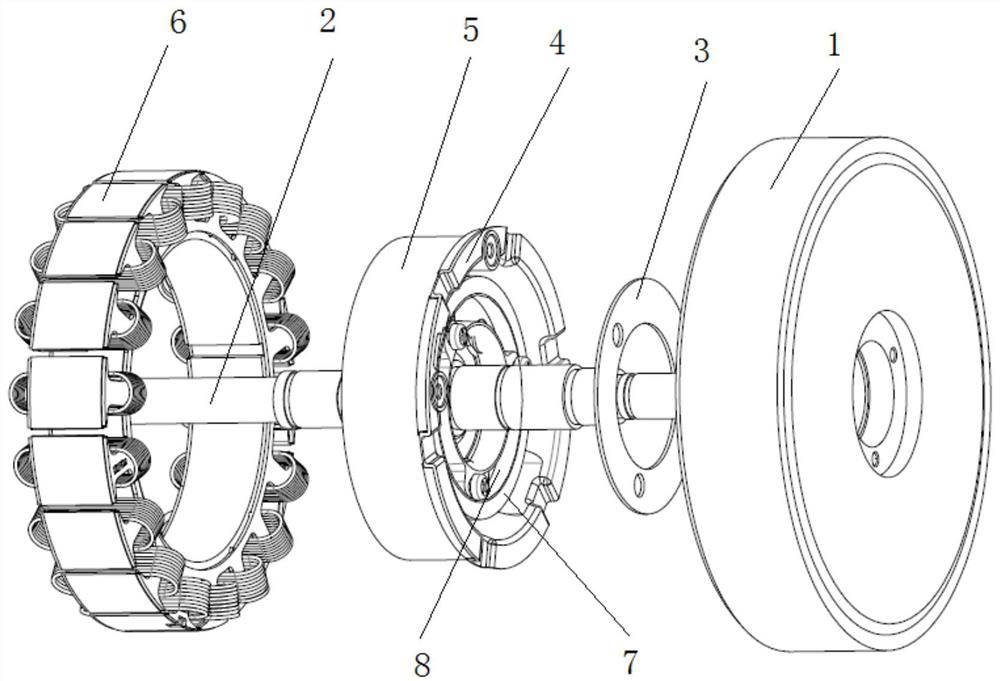

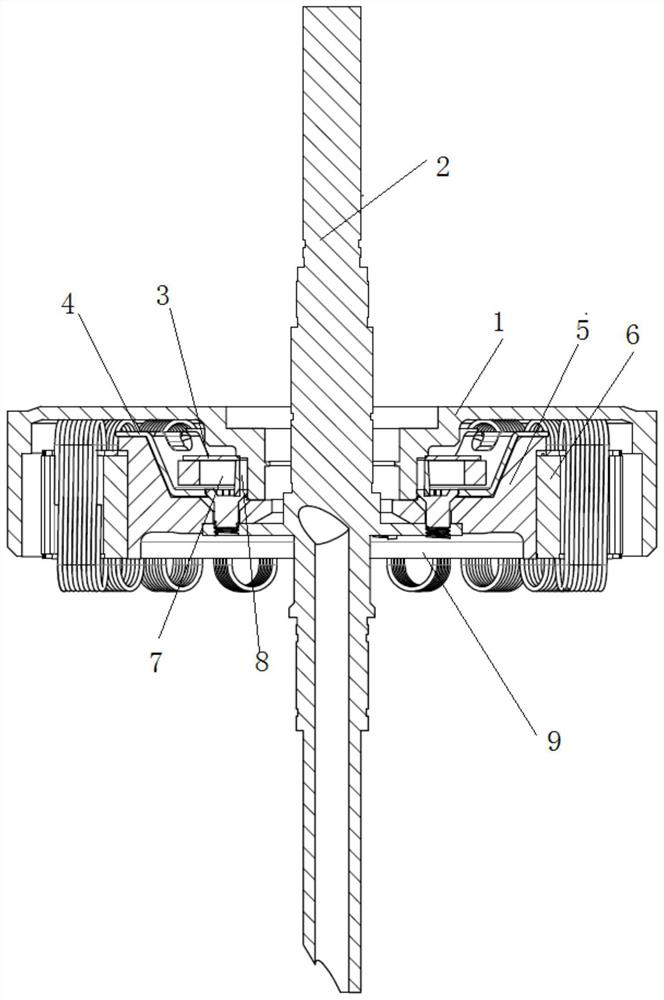

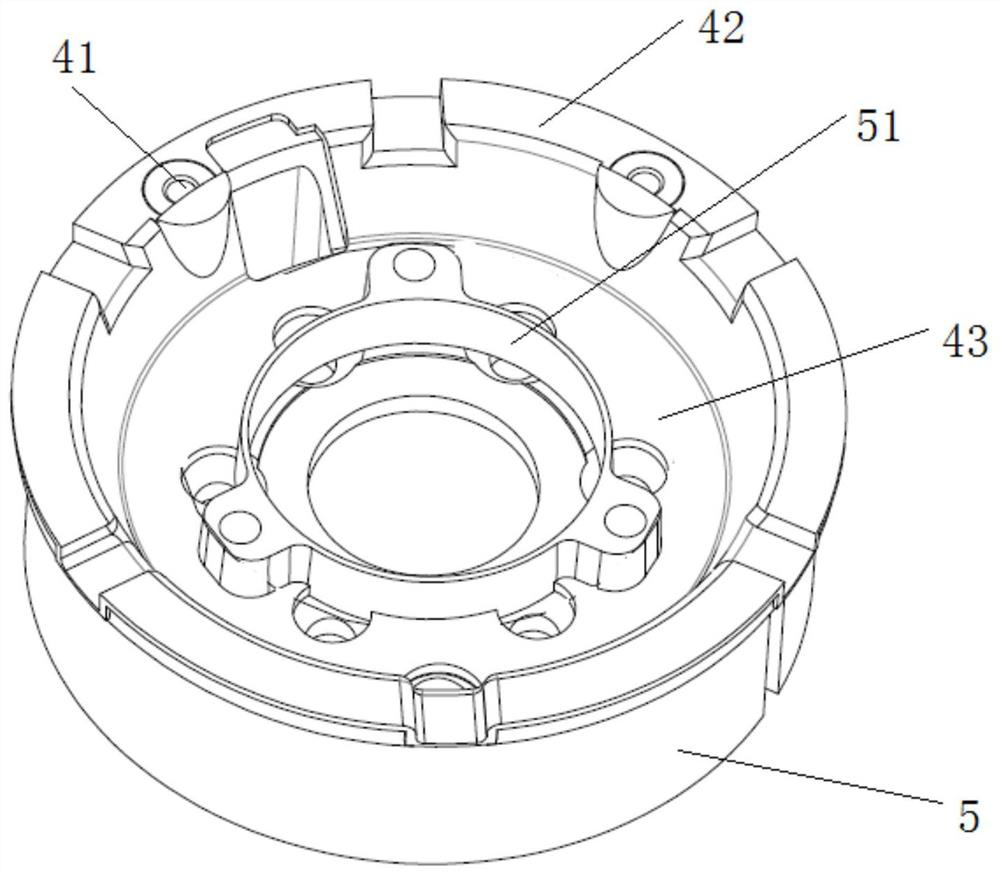

[0016] Such as figure 1 with figure 2 As shown, the high-precision motor core of the present invention includes a rotor 1 and a stator, and the stator includes a main shaft 2, an aluminum core 5 and a punching sheet 6, the punching sheet 6 is embedded with coil windings, the main shaft 2 is fixed on the aluminum core, and the punching sheet 6 is located on the outside of the aluminum core. The basic structure of the rotor and the stator will not be repeated here. The main shaft is provided with a flange 9, the flange is perpendicular to the axis of the main shaft, a screw hole is arranged on the flange, and a screw hole matched with the flange is arranged on the aluminum core, and the flange is fixed on the aluminum core through the screw hole. on the core. The aluminum core and the die are kept fixed by a flat key.

[0017] The main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com