Material conveying method and device based on intelligent driving

A technology for intelligent driving and materials, applied in logistics, instruments, data processing applications, etc., can solve problems such as low reliability, and achieve the effect of improving timeliness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

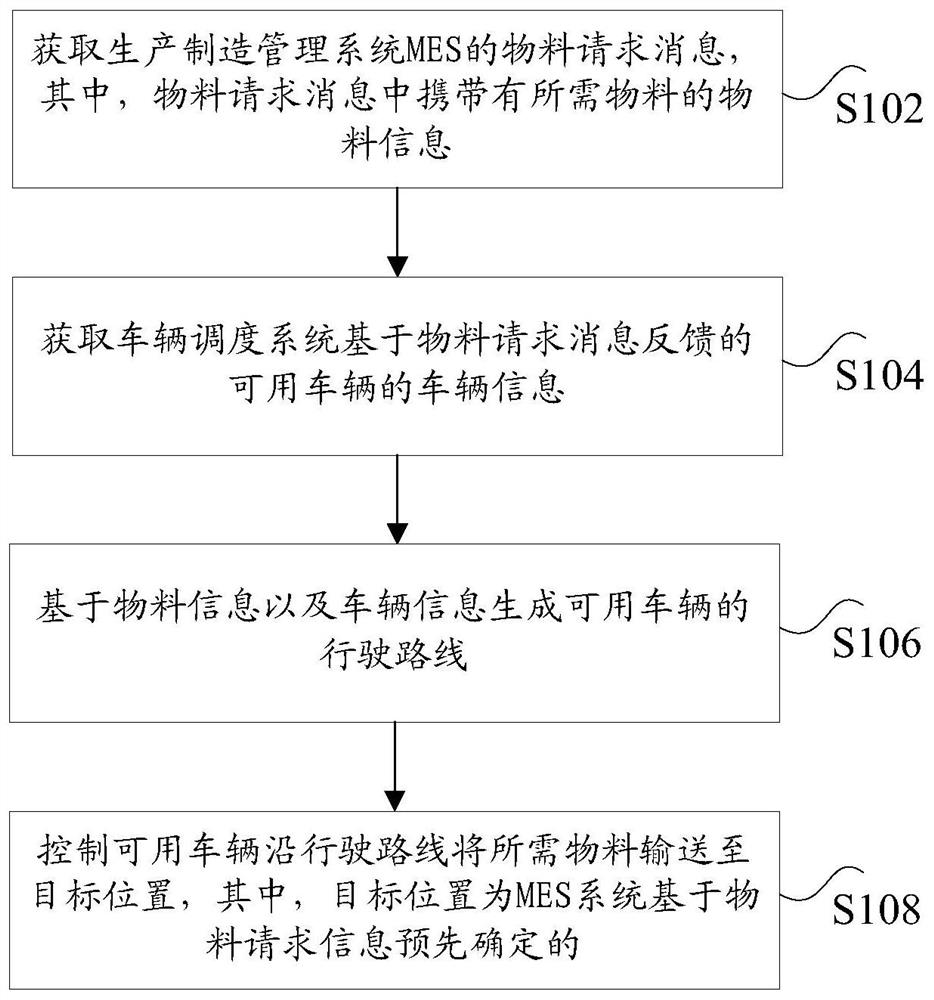

[0033] According to an embodiment of the present invention, a method embodiment of a material delivery method based on intelligent driving is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be implemented in a computer system such as a set of computer-executable instructions and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0034] figure 1 It is a flowchart of a material delivery method based on intelligent driving according to an embodiment of the present invention, such as figure 1 As shown, the material delivery method based on intelligent driving includes the following steps:

[0035] Step S102, obtaining a material request message from the MES, wherein the material request message carries material information of the required material.

[0036] The MES system here, that is, the manufacturing ...

Embodiment 2

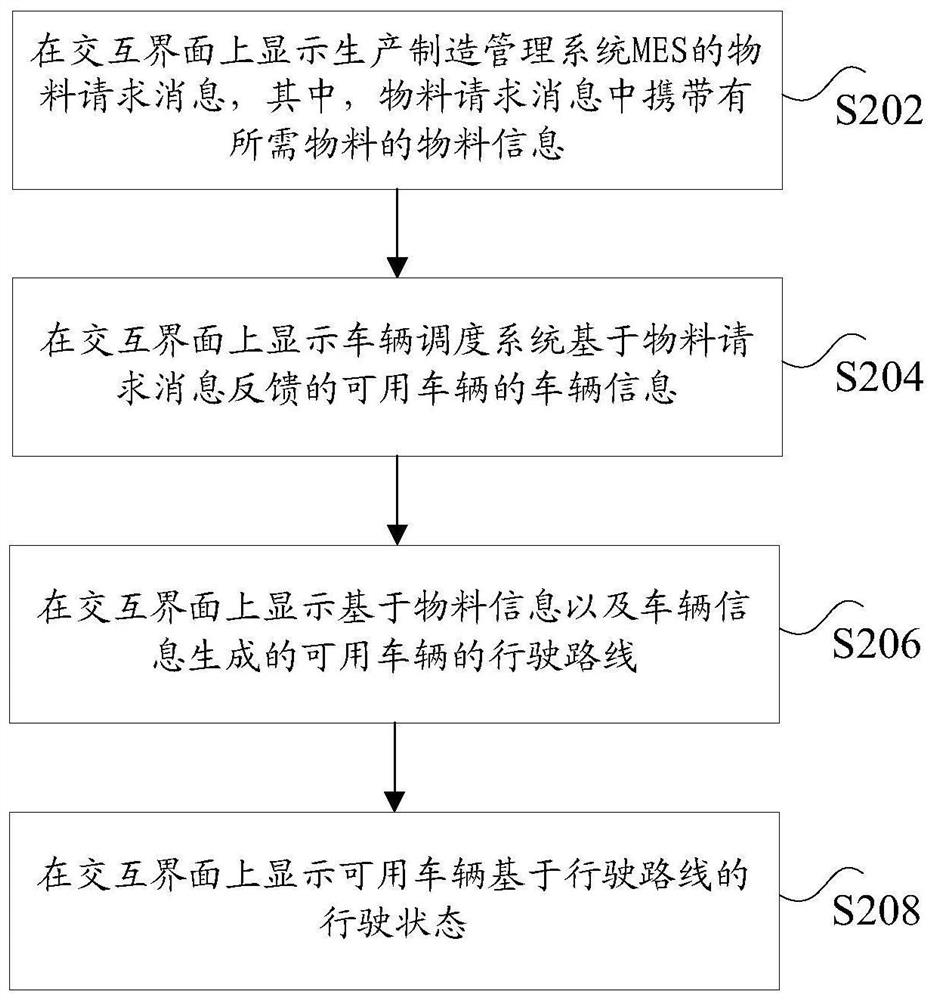

[0061] According to an embodiment of the present invention, a method embodiment of a material delivery method based on intelligent driving is also provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be implemented in a computer system such as a set of computer-executable instructions and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0062] figure 2 It is a flow chart of another material delivery method based on intelligent driving according to an embodiment of the present invention, such as figure 2 As shown, the material delivery method based on intelligent driving includes the following steps:

[0063] Step S202, displaying the material request message of the manufacturing management system MES on the interactive interface, wherein the material request message carries the material information of t...

Embodiment 3

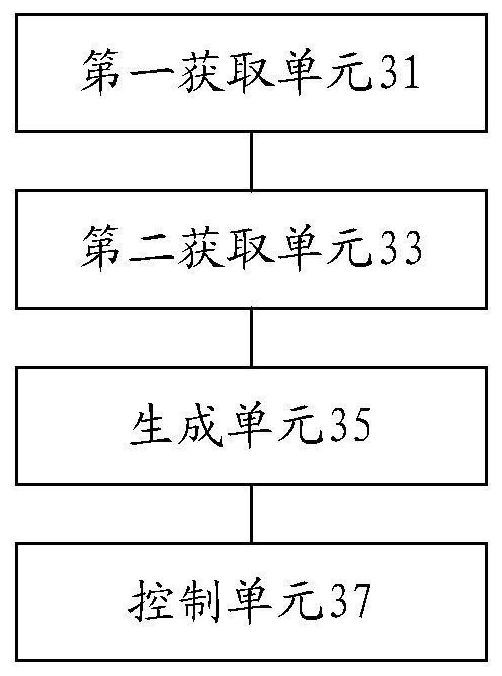

[0070] According to another aspect of the embodiment of the present invention, a material conveying device based on intelligent driving is also provided, image 3 is a schematic diagram of a material conveying device based on intelligent driving according to an embodiment of the present invention, such as image 3 As shown, the material conveying device based on intelligent driving may include: a first acquisition unit 31 , a second acquisition unit 33 , a generation unit 35 and a control unit 37 . The material conveying device based on intelligent driving will be described below.

[0071] The first acquiring unit 31 is configured to acquire a material request message of the MES, wherein the material request message carries material information of the required material.

[0072] The second obtaining unit 33 is configured to obtain vehicle information of available vehicles fed back by the vehicle dispatching system based on the material request message.

[0073] The generatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com