A semi-supervised integrated real-time learning method for soft measurement of Mooney viscosity of industrial rubber compounds

A glue Mooney and soft measurement technology, used in design optimization/simulation, special data processing applications, etc., can solve the problem of difficult real-time online measurement of Mooney viscosity parameters, and achieve the effect of improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

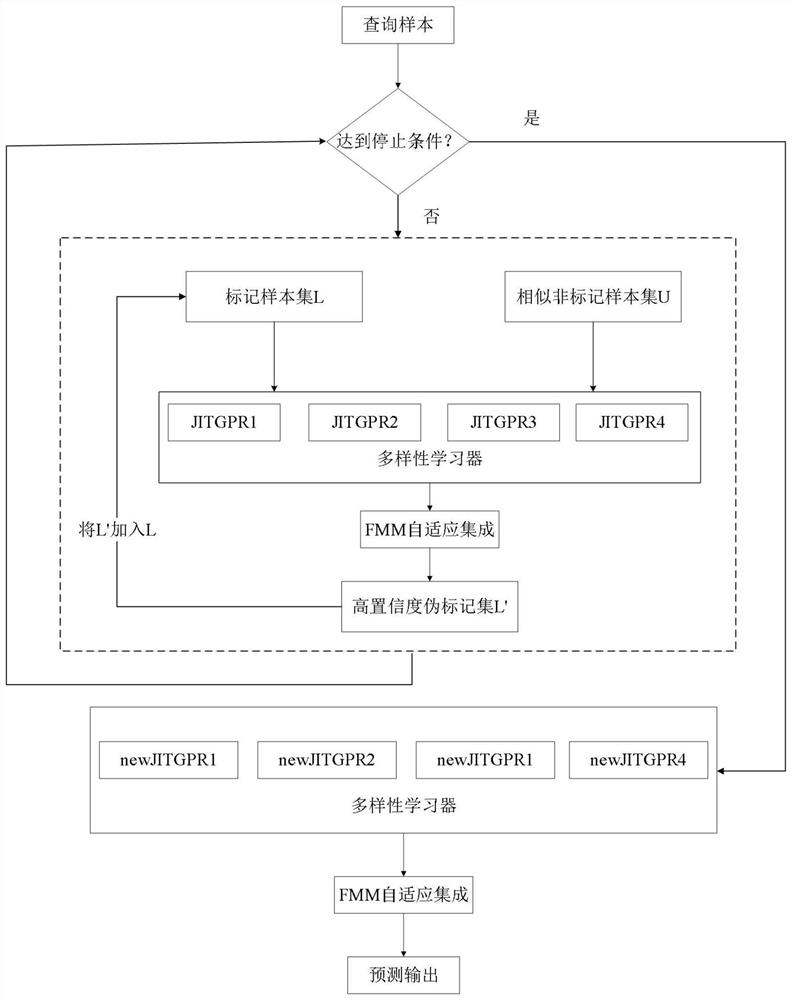

Method used

Image

Examples

Embodiment 2

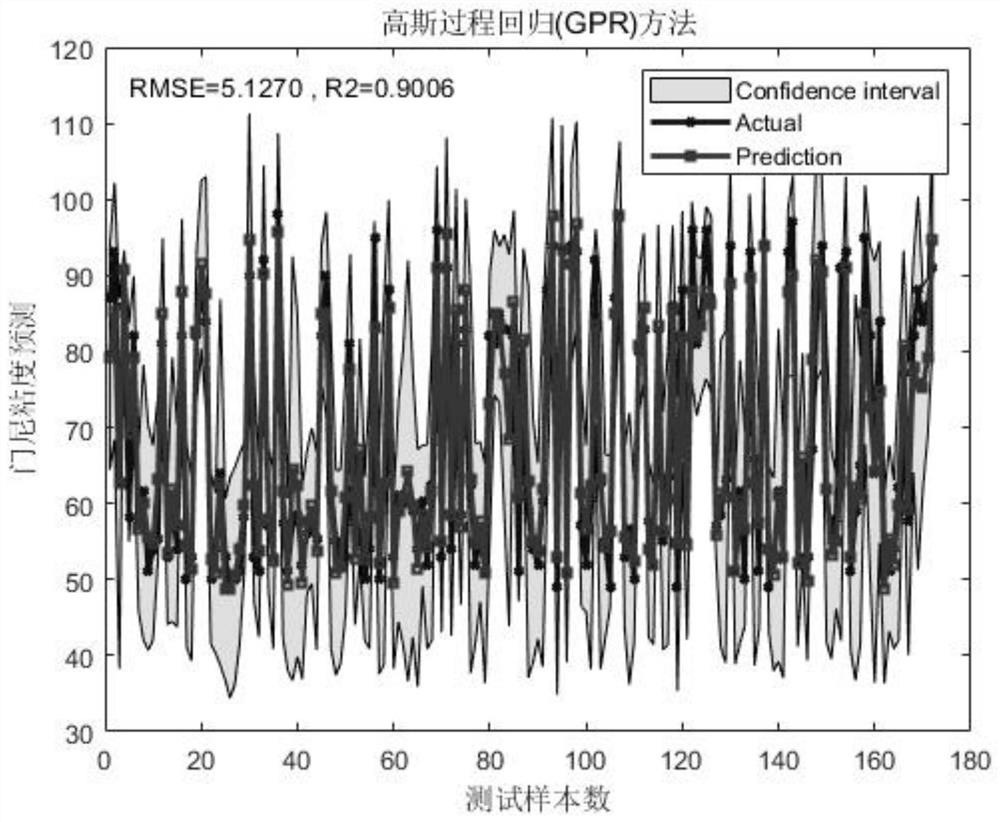

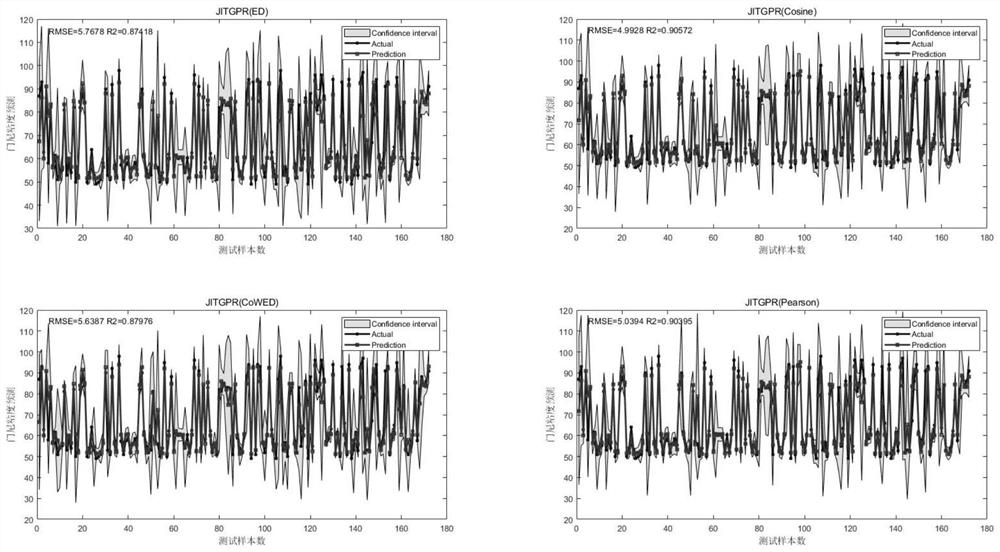

[0071] Embodiment 2: The performance of the SSEJITGPR method for Mooney viscosity prediction is illustrated below in conjunction with an example of the rubber mixing process in a specific industrial process of a tire manufacturer in East China. Industrial rubber mixing is a complex batch process. Mooney viscosity is a key parameter variable in the industrial rubber mixing process, but it is difficult to obtain it in real time. In order to control the product quality and production efficiency in the industrial rubber mixing process, Online real-time prediction of Mooney viscosity by soft-sensing modeling approach.

[0072] Mixing chamber temperature, motor power, impact pressure, motor speed and energy are five auxiliary variables that affect the selection of mass variable Mooney viscosity. In addition, process variables corresponding to time 0s, 14s, 18s, ..., 118s As auxiliary input variables, a total of 140 input variables were obtained.

[0073] A total of 1172 batches of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com