Method for preparing universal box-type skin antenna vibration test clamp

A vibration testing and skinning technology, applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve the problems of difficult design, indeterminate shape of the outer edge of the skin of the skinned antenna, and strong specificity, etc. Short design cycle, avoid blindness, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

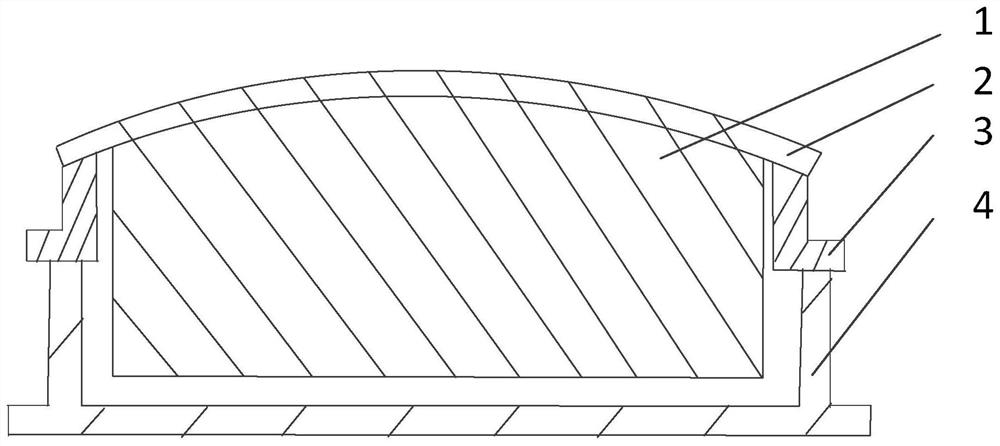

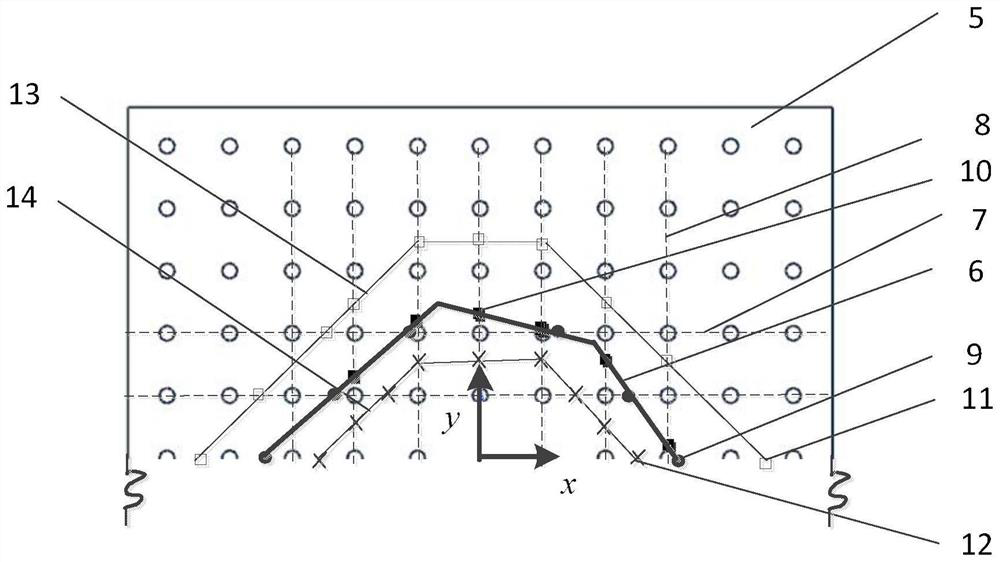

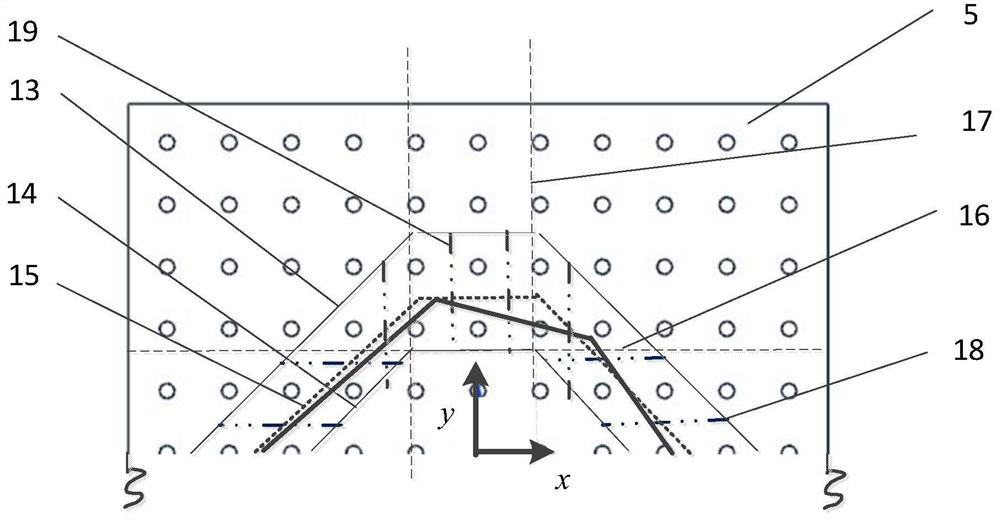

[0022] refer to Figure 1-Figure 4 . According to the present invention, comprise the steps:

[0023] Step 1: According to the actual use of the fixture, analyze the function, shape, weight, rigidity, structural characteristics, and material hardness of the parts, and mainly focus on Z-direction vibration, decompose the fixture into several components such as plates, beams, and ribs, and determine the fixture The geometric model of the fixture is designed according to the shape of the antenna skin and the test requirements, and the original three-dimensional solid model of the fixture is built: the center axis of the fixture is installed, and the center of the installation hole of the antenna skin 2 of the box skin is projected onto the vibration table. And connect the projection points of these skin mounting holes into a broken line 6, locate the outer edge line 11 of the bottom plate and the inner edge line 12 of the bottom plate through the intersection of the broken line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com