Shock-resistant base of manipulator

A manipulator, No. 1 technology, applied in mechanical equipment, engine components, springs/shock absorbers, etc., can solve problems such as poor anti-seismic effect of manipulators, and achieve low cost, reduced service life, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

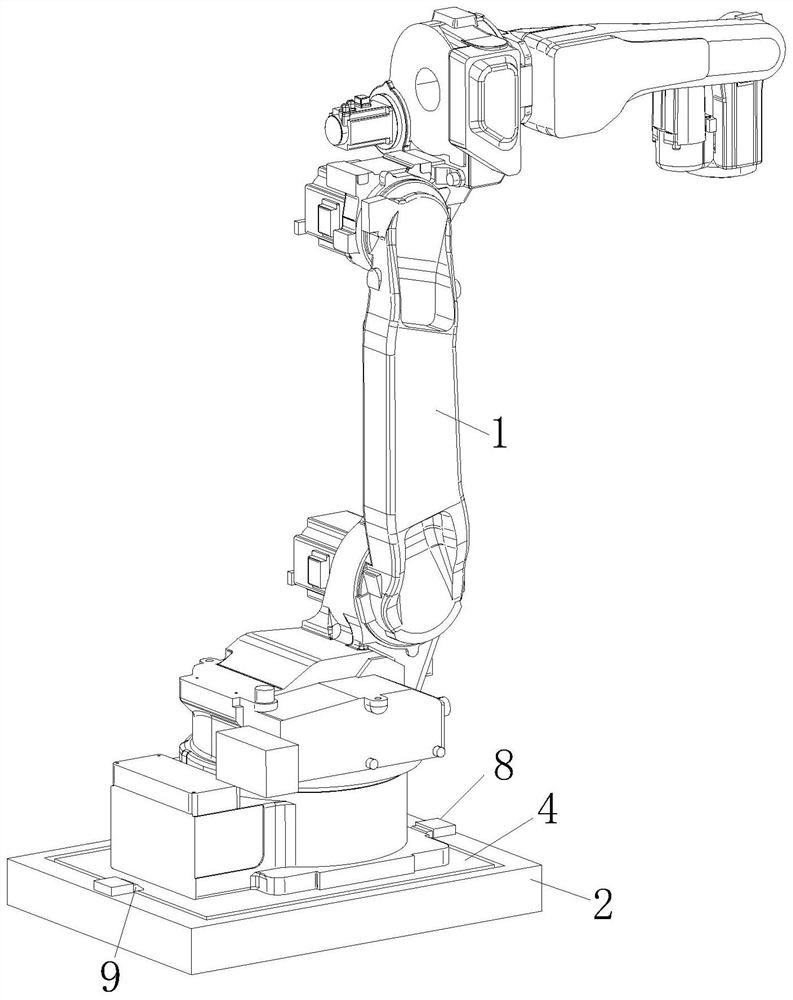

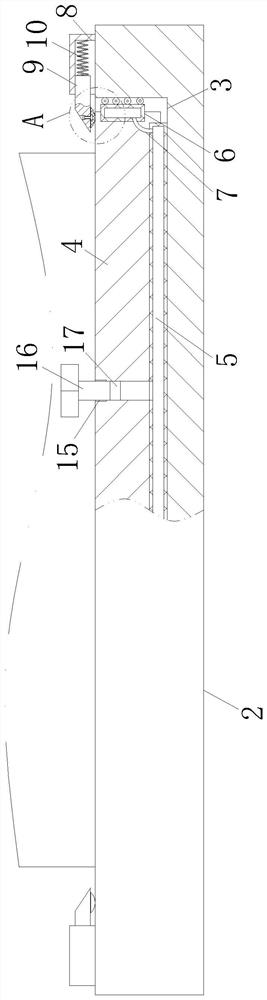

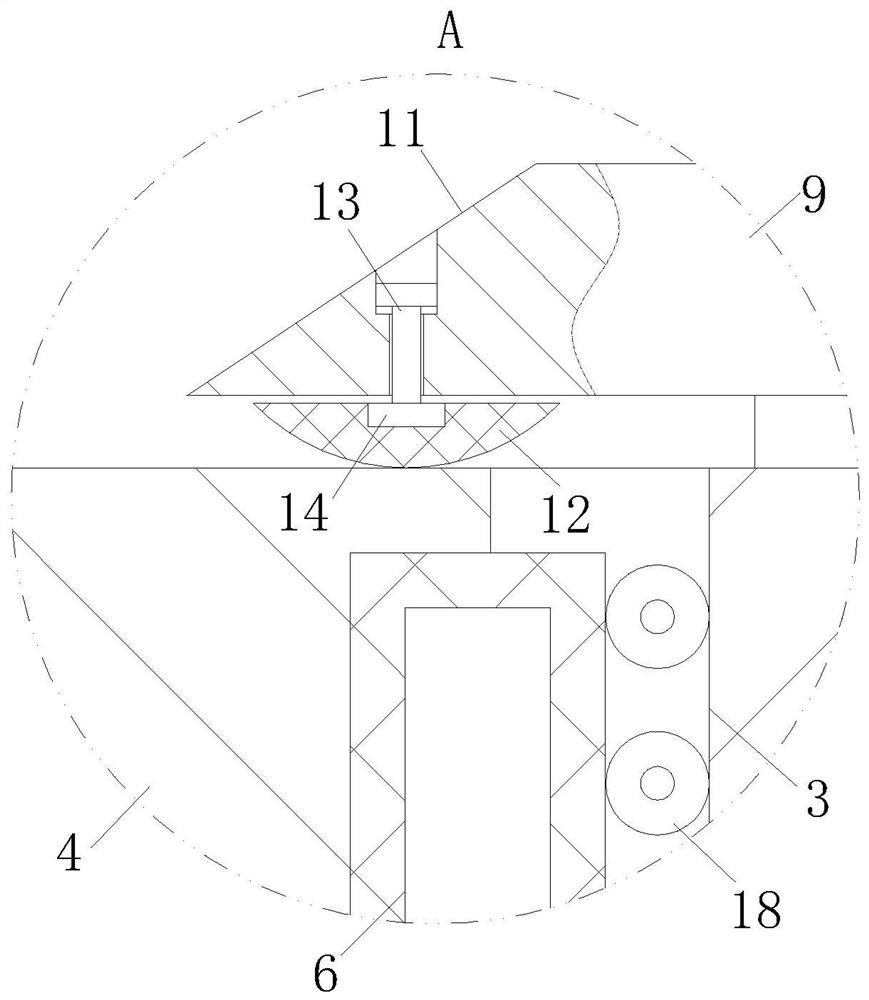

[0030] see Figure 1-5 As shown, a manipulator anti-seismic base according to the present invention includes a manipulator body 1 and a base 2; The mounting plate 4, the bottom end of the mounting plate 4 is provided with a No. 1 buffer bag 5, and the side walls of the mounting plate 4 are respectively provided with a No. 2 buffer bag 6, and the side wall of the No. 2 buffer bag 6 is connected to the installation cavity. There is a gap reserved between the side walls of 3, the No. 1 buffer bag 5 and the No. 2 buffer bag 6 are respectively connected through connecting pipes 7, and the No. 1 buffer bag 5 is connected between the installation plate 4 and the installation cavity 3 The internal gas can be pressed into the No. 2 buffer bag 6 under the extrusion of the No. 2 buffer bag 6, and the No. 2 buffer bag 6 is expanded to fit with the side wall of the installation cavity 3; during work, the base 2 in the prior art passes through The complex electric structure and the install...

Embodiment 2

[0040] see Image 6 As shown, the support ring 19 is provided with a feed port 30 on the side wall corresponding to the air outlet groove 20, the feed port 30 is provided with a blocking block 31, and the support ring 19 at the feed port 30 is There is an elastic net 32 that can wrap and squeeze the blocking block 31; during operation, when the rotating column 18 is working, the blocking block 31 can block the feed port 30 under the pressure of the elastic net 32, thereby The lubricating oil inside the support ring 19 can be preserved to reduce the outflow of the lubricating oil inside the support ring 19 when it is rotating. When the feed port 30 is opened, the lubricating oil can be replenished to the inside of the support ring 19, making the replenishment of the lubricating oil in the rotating column 18 more convenient and quick.

[0041]Working principle: Insert the mounting plate 4 at the bottom of the manipulator into the installation cavity 3, and the opening of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com