High-temperature fan based on heat insulation mechanism

A high-temperature, fan technology, applied to machines/engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of reducing the strength of the rotating shaft, bending and breaking of the rotating shaft, and guarantee the service life , the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

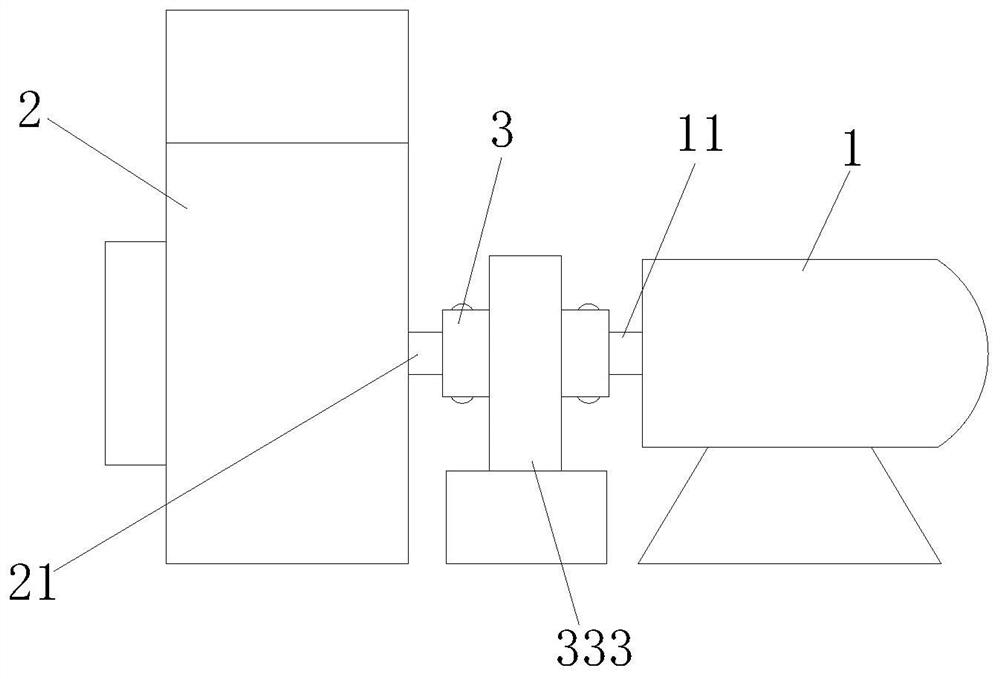

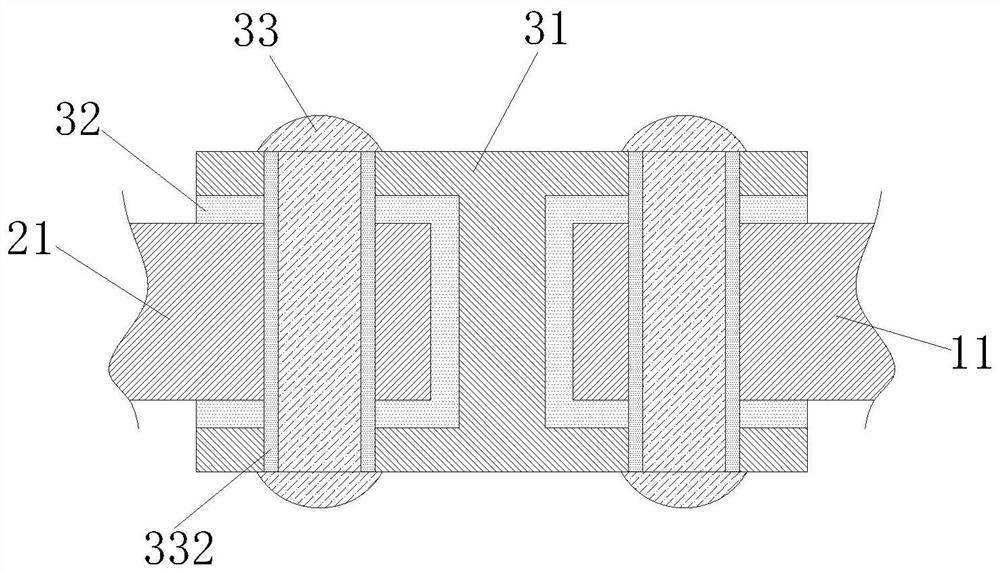

[0017] Embodiment 1, referring to the accompanying drawings, the high-temperature fan based on the heat insulation mechanism includes a motor 1 and an impeller device 2; the motor 1 is provided with a motor main shaft 11; the impeller device 2 is provided with a driven shaft 21; The motor main shaft 11 and the driven shaft 21 are connected by transmission;

[0018] A heat insulating device 3 is arranged between the motor main shaft 11 and the driven shaft 21; the heat insulating device 3 includes a connecting seat 31; the two ends of the connecting seat 31 are respectively fixedly connected to the motor main shaft 11 and the driven shaft 21 ; The connection between the connecting seat 31 and the motor main shaft 11 and the driven shaft 21 is provided with a first heat insulating member 32;

[0019] The setting of the connecting seat 31 is used to connect the motor main shaft 11 and the driven shaft 21, realize the transmission connection of the motor main shaft 11 and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com