Rotational friction energy dissipation-SMA coupling pseudo-classic building self-resetting steel joint and method

A technology of rotational friction and -SMA, applied to buildings, building components, building types, etc., can solve problems such as failure to continue normal use, damage to structural systems, and difficulty in repairing structures, so as to avoid permanent plastic damage, controllable damage, and avoid cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

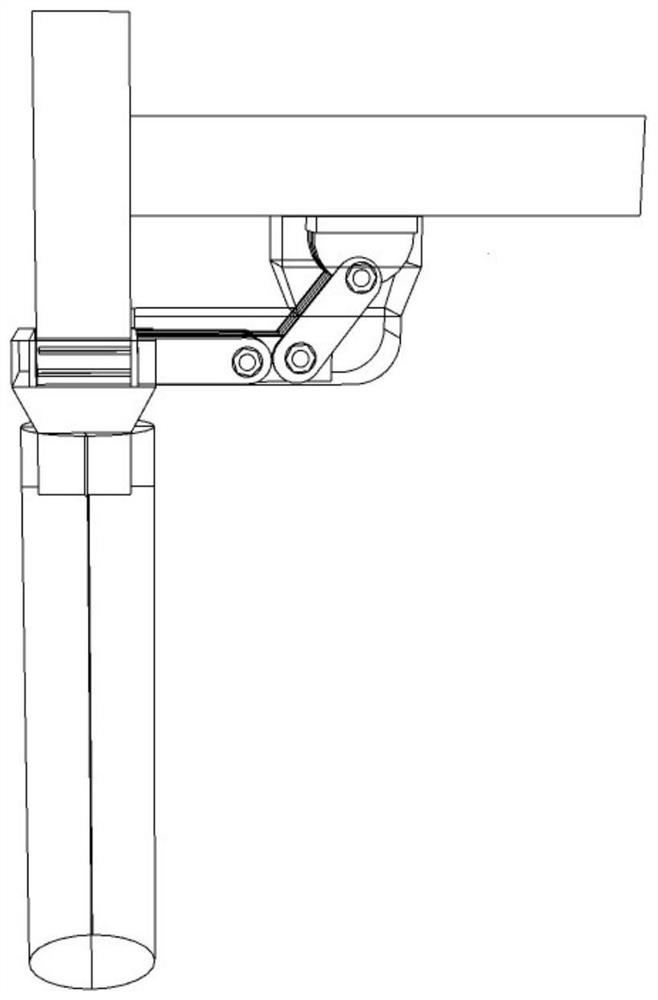

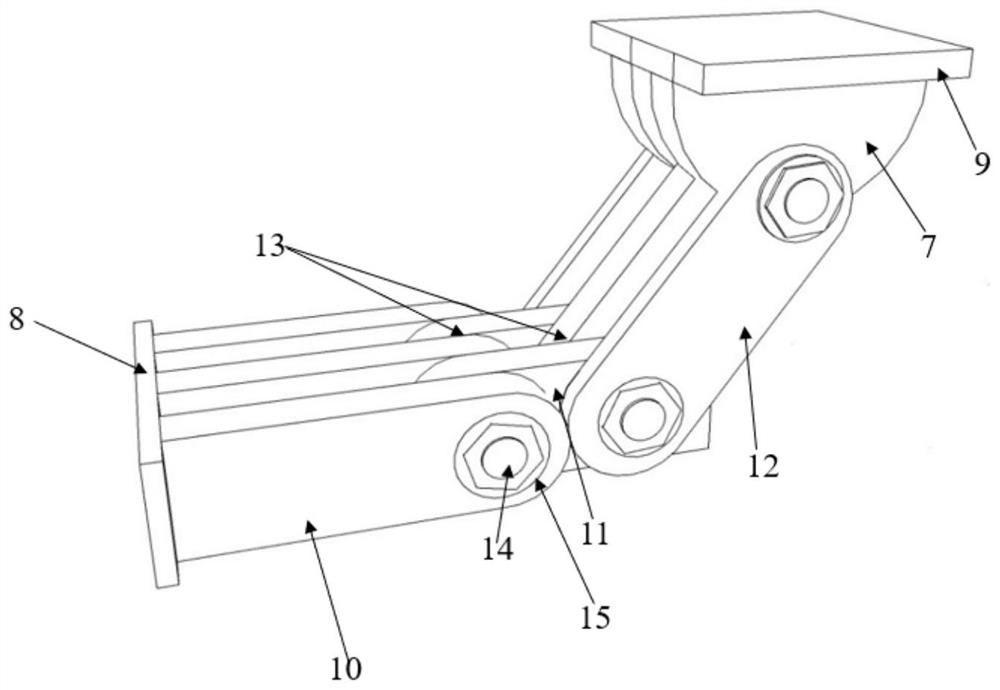

[0036] Such as figure 1 , figure 2 As shown, a self-resetting steel node of an antique building based on rotational friction energy dissipation-SMA coupling, including a beam-column node composed of a round steel tube lower column 1, a square steel tube upper column 2 and a rectangular cross-section steel beam 3, under the round steel tube A bucket gong component is arranged at the joint between the column 1 and the upper column 2 of the square steel pipe. The bucket gong component includes a lower bucket component 16, a gong component 17 and an upper bucket component 18, and a rotational friction energy dissipator is installed in the gong component 17, and the rotational friction energy dissipation The device is connected to the nodes of the lower column 1 of the round steel pipe and the upper column 2 of the square steel pipe through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com