Reticular film reinforced aluminum-based material and preparation method thereof

A technology for reinforcing aluminum-based and reticulated films, applied in the field of high-performance aluminum alloy composite materials, can solve problems such as particle reinforcement agglomeration, and achieve the effects of improving bonding strength, improving mechanical properties, and ensuring mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of SiC reinforced modified mesh electrospinning membrane comprises the following steps:

[0036] (1) Dissolve a certain amount of cellulose powder, PVA and NaCl in water, stir to dissolve, and then ultrasonically disperse to obtain a 3.2wt% cellulose electrospinning solution;

[0037] (2) dissolving ethyl orthosilicate in acidic aqueous solution, then adding ethanol, the mass ratio of ethyl orthosilicate and acidic aqueous solution is 1:3, and the final volume ratio of described ethanol and acidic aqueous solution is 1:4, After stirring evenly, place it in an oven for hydrolysis to obtain a sol electrospinning solution with a certain viscosity;

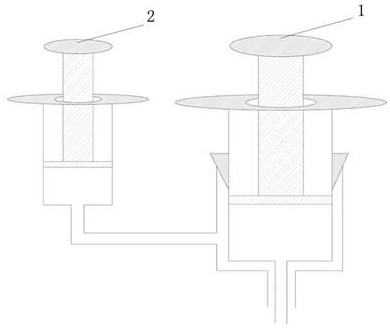

[0038] (3) The electrospinning solution prepared in step (1) and step (2) is electrospun with coaxial double nozzles, wherein the cellulose electrospinning solution is used as the core layer, and the sol electrospinning solution is used as the cortex , to obtain an electrospinning film, wherein, the para...

Embodiment 2

[0042] The preparation method of SiC reinforced modified mesh electrospinning membrane comprises the following steps:

[0043] (1) Dissolve a certain amount of cellulose powder, PVA and NaCl in water, stir to dissolve, and then ultrasonically disperse to obtain a 6.5wt% cellulose electrospinning solution;

[0044] (2) dissolving ethyl orthosilicate in acidic aqueous solution, then adding ethanol, the mass ratio of ethyl orthosilicate and acidic aqueous solution is 1:5, and the final volume ratio of described ethanol and acidic aqueous solution is 1:2, After stirring evenly, place it in an oven for hydrolysis to obtain a sol electrospinning solution with a certain viscosity;

[0045] (3) The electrospinning solution prepared in step (1) and step (2) is electrospun with coaxial double nozzles, wherein the cellulose electrospinning solution is used as the core layer, and the sol electrospinning solution is used as the cortex , to obtain an electrospun film, wherein, the paramete...

Embodiment 3

[0049] The preparation method of SiC reinforced modified mesh electrospinning membrane comprises the following steps:

[0050] (1) Dissolve a certain amount of cellulose powder, PVA and NaCl in water, stir to dissolve, and then ultrasonically disperse to obtain a concentration of 4.4wt% cellulose electrospinning solution;

[0051] (2) dissolving ethyl orthosilicate in acidic aqueous solution, then adding ethanol, the mass ratio of ethyl orthosilicate and acidic aqueous solution is 1:3, and the final volume ratio of described ethanol and acidic aqueous solution is 1:4, After stirring evenly, place it in an oven for hydrolysis to obtain a sol electrospinning solution with a certain viscosity;

[0052] (3) The electrospinning solution prepared in step (1) and step (2) is electrospun with coaxial double nozzles, wherein the cellulose electrospinning solution is used as the core layer, and the sol electrospinning solution is used as the cortex , to obtain an electrospinning film, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com