Uninterrupted unreeling equipment and unreeling method using same

A technology of unwinding equipment and unwinding shaft, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., which can solve the problems affecting the improvement of production efficiency and the inability to uninterrupted unwinding, so as to improve production efficiency , cost-effective, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

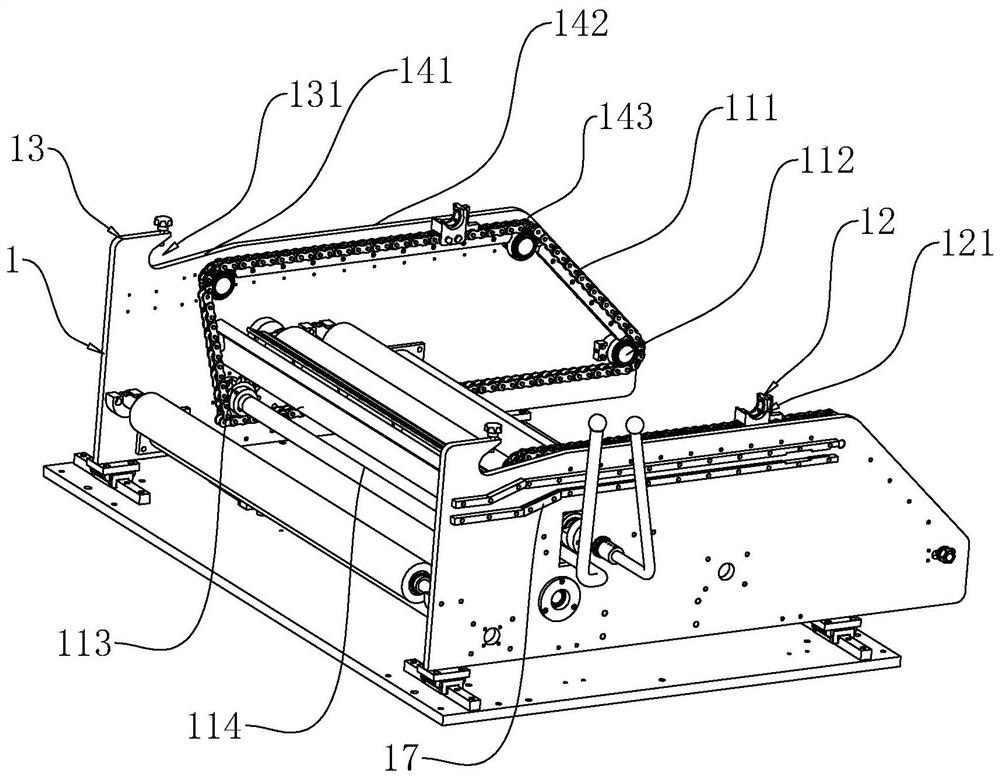

[0054] The following is attached Figure 1-9 The application is described in further detail.

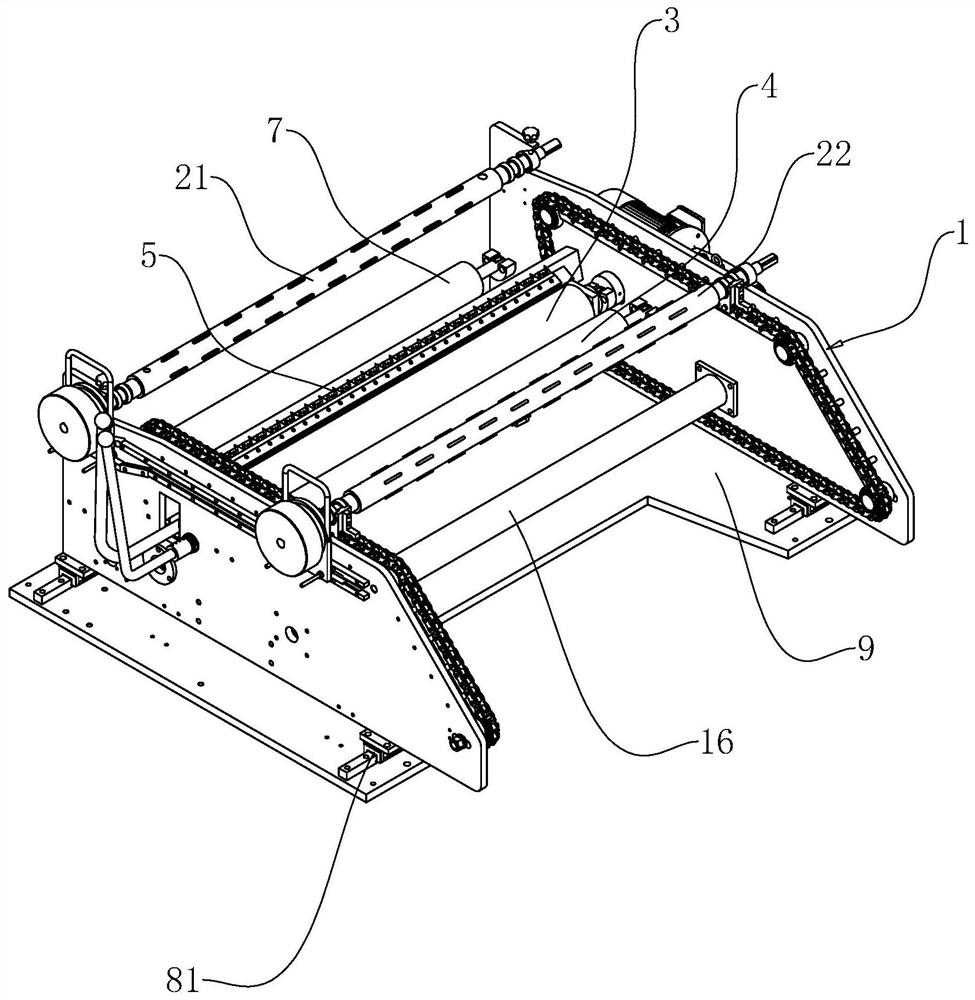

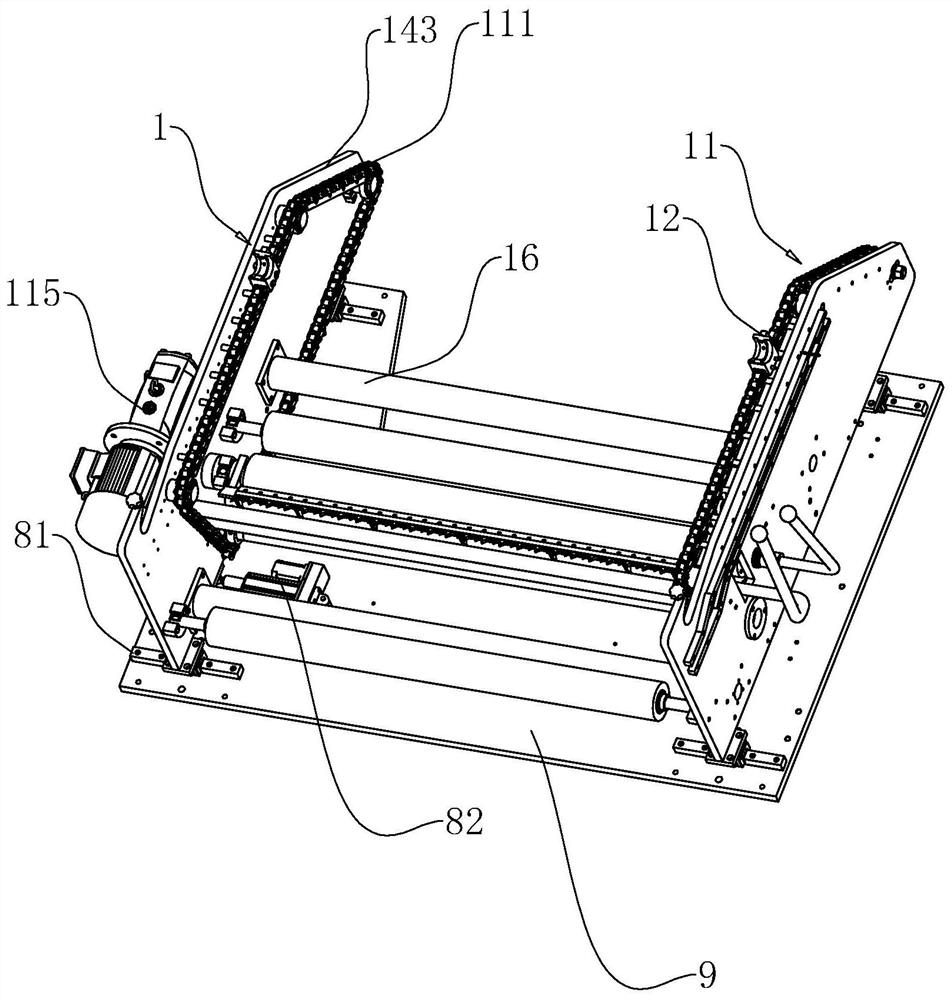

[0055] The embodiment of the present application discloses an uninterrupted unwinding device, which is used for unwinding a film. refer to figure 1 , an uninterrupted unwinding device, including a bottom plate 9, a support member 1, a first unwinding shaft 21, a second unwinding shaft 22, a pressure roller 3, a receiving roller 4, a cutter 5 and a transition roller 7.

[0056] refer to figure 1 and figure 2 , the support member 1 is a vertically elongated support plate, one long side of which is connected to the horizontally arranged bottom plate 9 through two slide rails 81 . There are two support members 1, which are parallel and symmetrical. A reinforcing rod 16 is installed between the two supporting parts 1 in the transverse direction (the direction of the vertical connection of the two supporting parts 1, the same below) through screws; the reinforcing rod 16 connects the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com