Gas collecting device and filling machine

A technology of gas collecting device and cylinder, which is applied in the directions of packaging, packaging protection, transportation and packaging, can solve the problems of inability to adjust the depth of the charging gun, and achieve the effect of improving the collection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

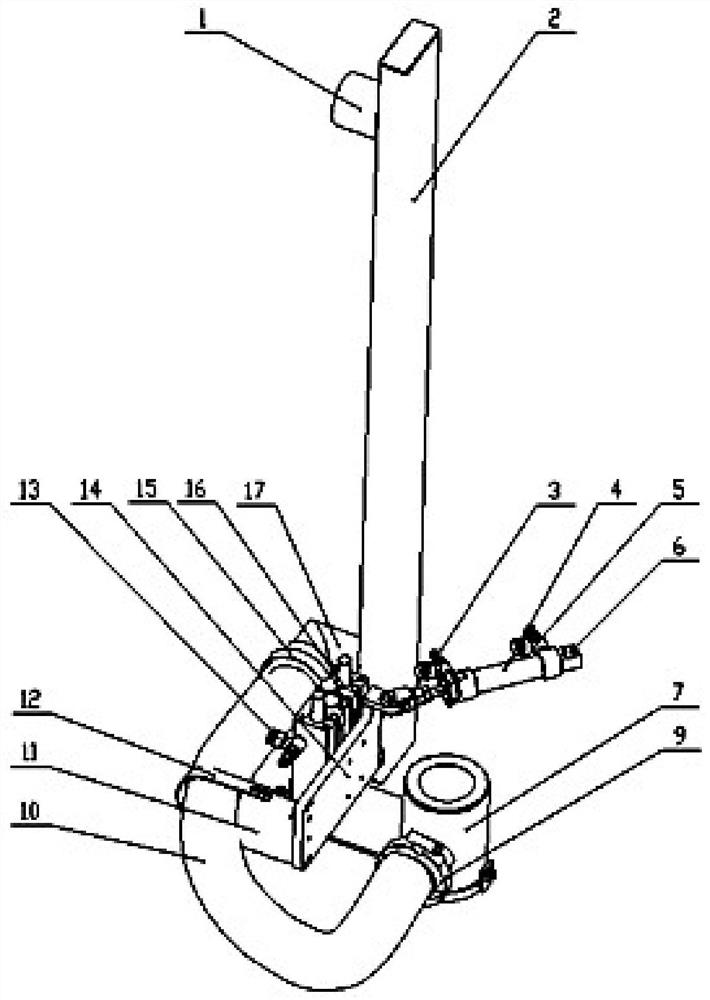

[0021] Such as figure 1 As shown, the present embodiment provides an air collecting device, including an air collecting hood 7, a flexible air duct 10, a mounting plate 14, a lifting cylinder 16 and a swinging cylinder 4, wherein the lifting cylinder 16 is fixedly connected to the mounting plate 14, The piston rod at the lower end of the lifting cylinder 16 is fixedly connected with the wind collecting hood 7 through a connecting plate arranged horizontally; The first support hinge seat is hinged, the rear side of the lifting cylinder 16 is hinged to the second support hinge seat, and the distance between the wind collecting hood 7 and the second support hinge seat is greater than the distance between the hinge shaft and the second support hinge seat, The swing cylinder 4 can drive the wind collecting hood 7 to swing more substantially than the hinge shaft; One end of the flexible air duct is connected, and the other end of the flexible air duct is fixedly connected to the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com