Hardware paint spraying and drying robot

A robot and hardware technology, applied in the direction of surface pretreatment, coating, and liquid coating device on the surface, etc., can solve the problems of dry cracking of the paint surface, high temperature of hot air on the paint surface, and small surrounding heat, etc. The effect of increasing the angle, increasing the diffusion surface, and preventing reverse advance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached figure 1 to attach Figure 6 Shown:

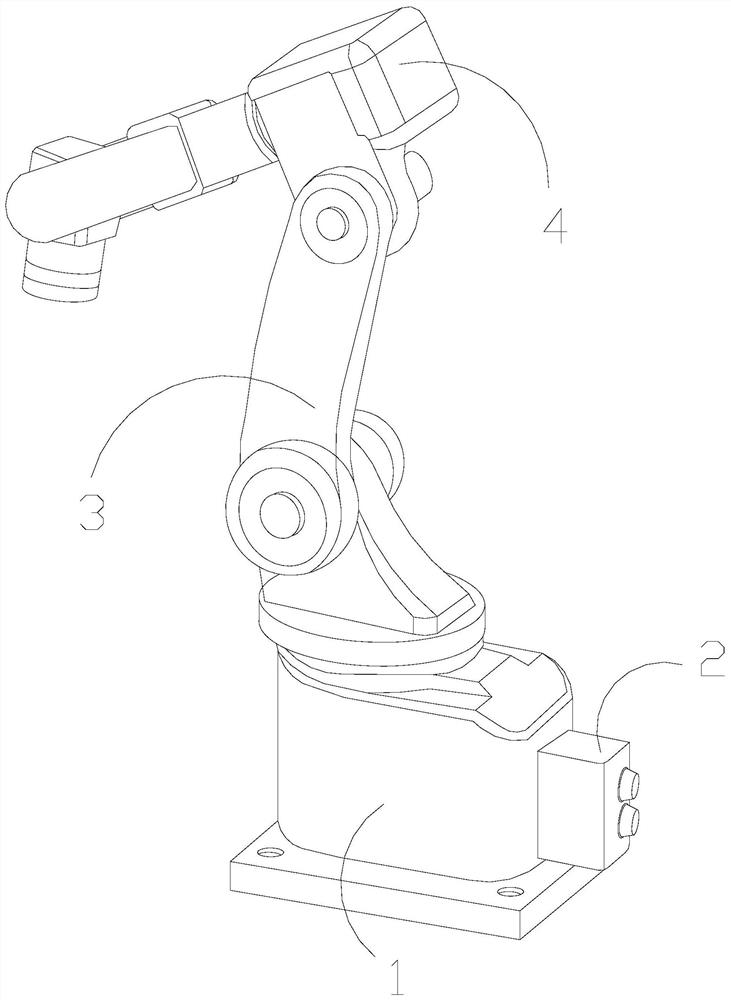

[0032] The invention provides a metal spraying and drying robot, the structure of which is provided with a base 1, a control box 2, a support arm 3, and a drying system 4, the control box 2 is installed on one side of the base 1, and the support arm 3 is movable Connected above the base 1, one end of the drying system 4 is hingedly connected with the support arm 3 and movably matched.

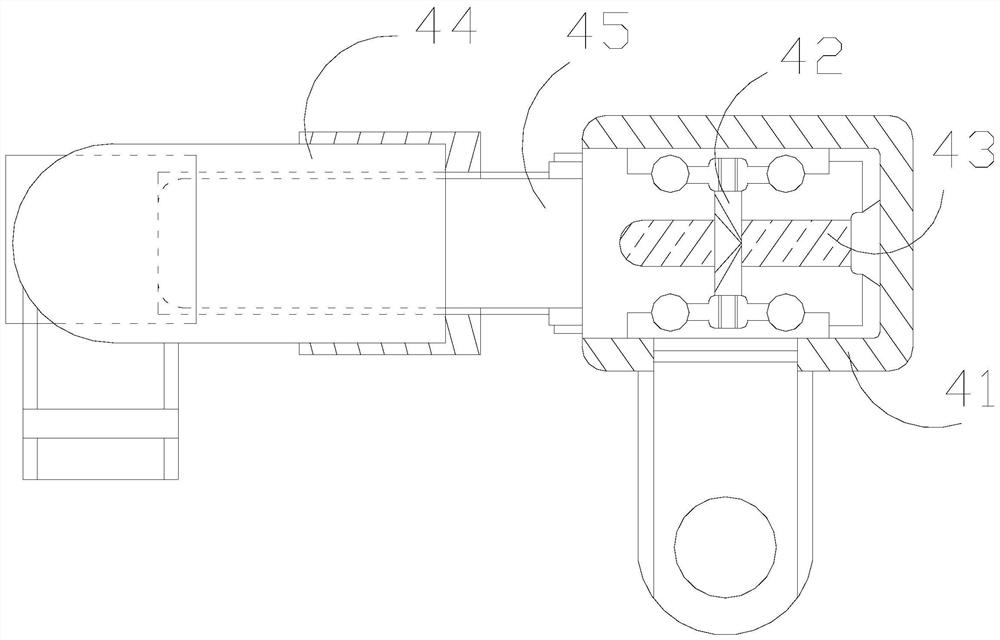

[0033] The drying system 4 is provided with a rear box 41, an air rack 42, a ceramic tube 43, a drying head 44, and a heat pipe cavity 45. The air rack 42 is embedded and installed inside the rear box 41, and the ceramic tube 43 is located In the box 41 , the heat pipe cavity 45 communicates with the rear box 41 , and the drying head 44 is movably matched with the heat pipe cavity 45 .

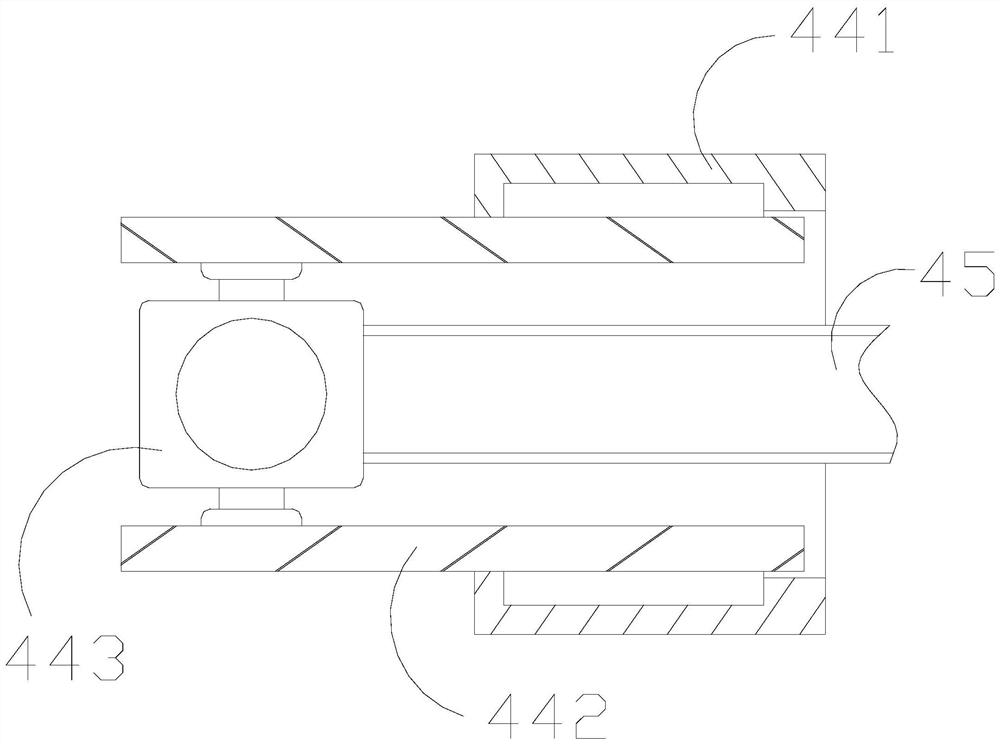

[0034] Wherein, the drying head 44 is provided with a sliding plate 441, a side plate 442, and a movable column 443, the sliding plate 441 is ring-con...

Embodiment 2

[0040] as attached Figure 7 to attach Figure 9 Shown:

[0041] Wherein, the movable ball q3 is provided with a weight q31, a variable ring q32, and a telescopic frame q33. The variable ring q32 has a ring structure and has toughness, and can be expanded and contracted. The weight q31 has a heavy pressure, and the telescopic frame q33 can perform telescopic activities. The weight q31 is In the variable ring q32, through the telescopic elasticity of the telescopic frame q33, pressure is exerted on the variable ring q32 to make it flexibly change its own ring diameter, so that the movable ball q3 as a whole continuously expands and contracts.

[0042] Wherein, the flap opening q4 is provided with a rubber pulling edge q41, an air cushion q42, an air flow port q43, and a front plate q44, the air cushion q42 is connected between the rubber pulling edges q41, and the air flow opening q43 and the air cushion q42 are an integrated structure And located below it, the front plate q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com