Integrated kitchen waste treatment device

A technology for kitchen waste and treatment device, which is applied in the field of integrated kitchen waste treatment device, can solve the problems of complex installation, large floor space, and many manpower, so as to reduce site occupation, reduce equipment design cost and manufacturing cost , The effect of preventing pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with the accompanying drawings and examples, the specific implementation of the present invention will be further described in detail, the following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

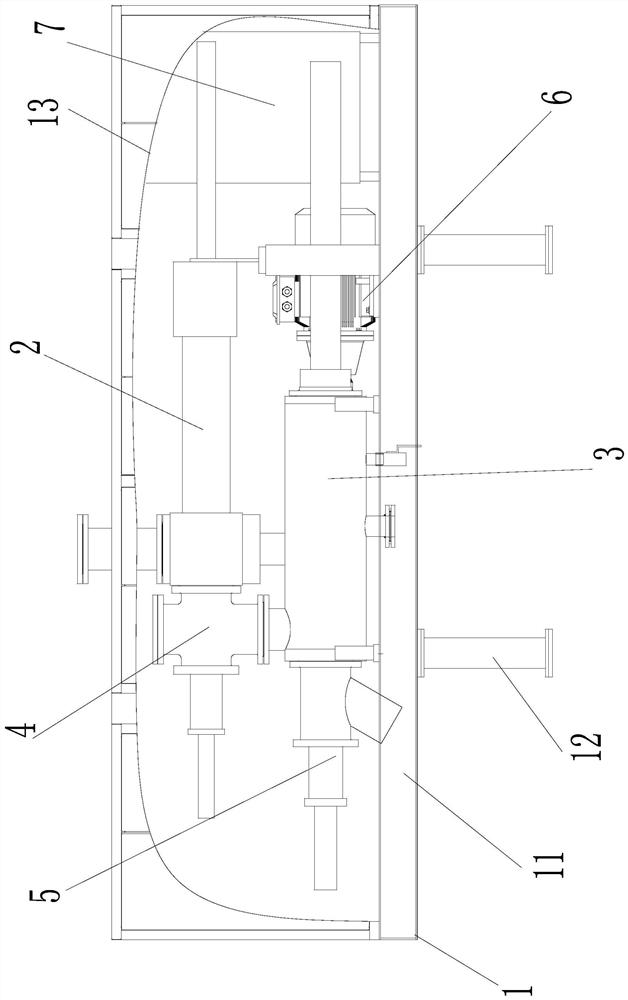

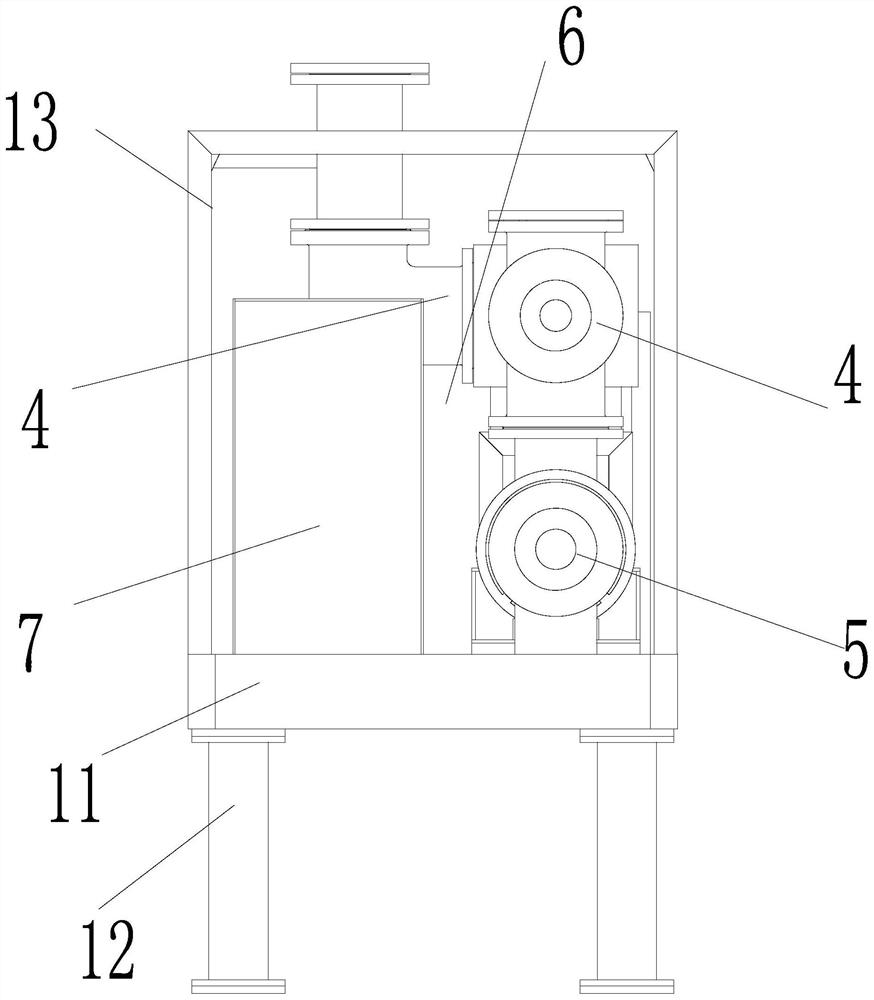

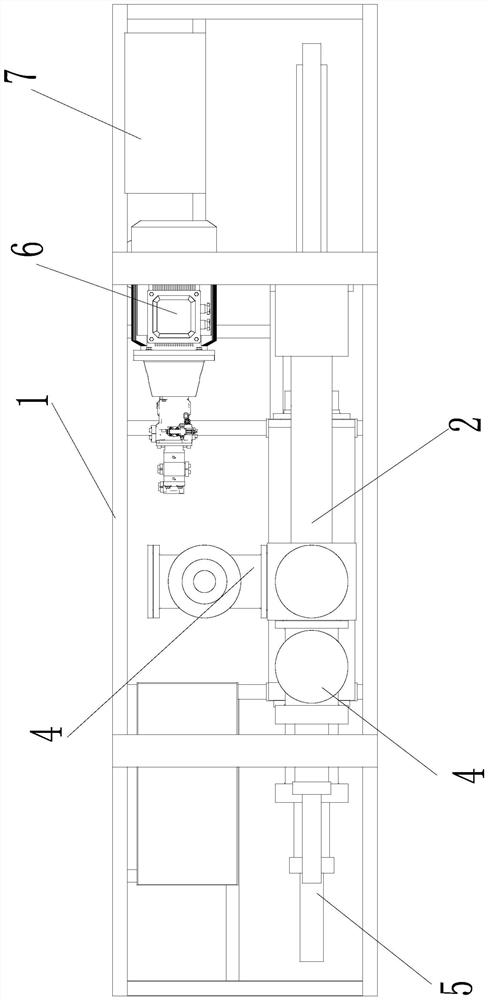

[0027] Such as Figure 1-Figure 3 As shown, the present invention provides an integrated food waste treatment device, which can automatically suck the crushed and fermented food waste into the equipment, separate the solid material from the liquid material, and then automatically send the separated material out. The present invention includes a frame 1, a single cylinder pump 2, a slurry filter 3, two plunger valves 4, a slag discharge valve 5, a hydraulic system 6 and an electrical control system 7, and all equipment in the device are integrated in the frame 1, the transportation and slag discharge of food waste are automatically controlled by the electrical control system 7, which has the adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com