Wind turbine, wind turbine rotor blade and blade bearing for a wind turbine

A technology of rotor blades and supporting devices, which is applied in wind power generation, mechanical equipment, and wind turbines in the same direction as the wind. It can solve problems such as bolt overload and achieve the effect of reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

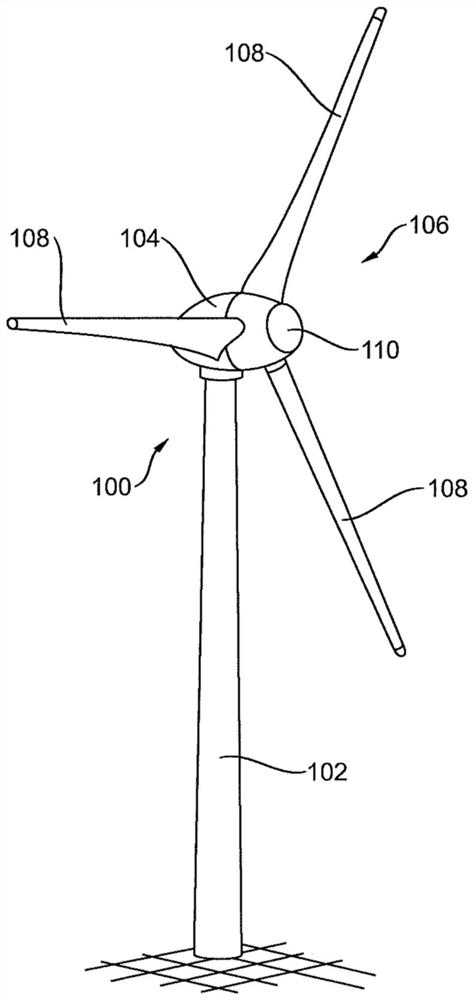

[0036] figure 1 A wind energy installation 100 is shown with a tower 102 and a nacelle 104 . A rotor 106 with three rotor blades 108 and a spinner 110 is arranged on the pod 104 . The rotor blade 108 is arranged with its rotor blade flange on the rotor hub. The rotor 106 is set in rotational motion by the wind in operation and thus drives a (not shown) generator in the nacelle 104 .

[0037] figure 2 show the basis figure 1 cutaway view of a part of a wind energy plant. The rotor blades 108 are here rotatably mounted on the rotor hub 114 by means of the blade bearing 10 .

[0038] The rotor blades 108 and the hub 114 are formed coaxially to the bearing 10 and symmetrically about the axis of rotation 15 .

[0039] The rotor blade 108 includes a rotor blade flange 112 and a blade lamination 116 extending in the longitudinal direction of the rotor blade 108 . The blade laminate 116 is preferably made of fiber composite material with a central circumference U R hollow col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com