Hoisting and overturning integrated device for thin-wall type workpiece

A workpiece and thin-walled technology is applied in the field of integrated devices for lifting and turning over thin-walled workpieces, which can solve the problems of difficult processing and transportation of thin-walled workpieces, and achieve the effects of strengthening rigidity, saving processes, and avoiding knife vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

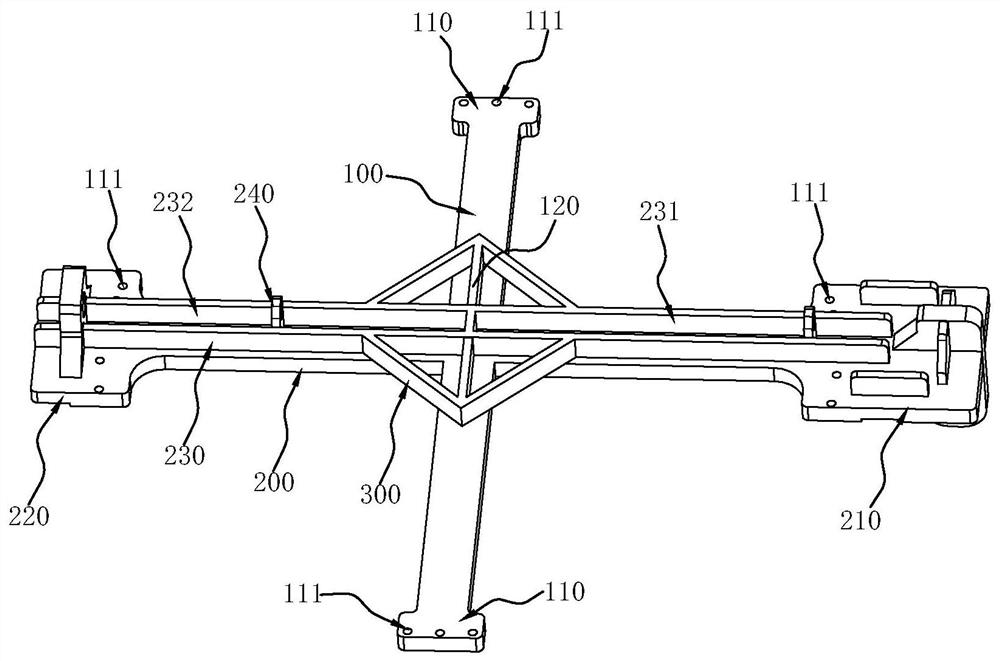

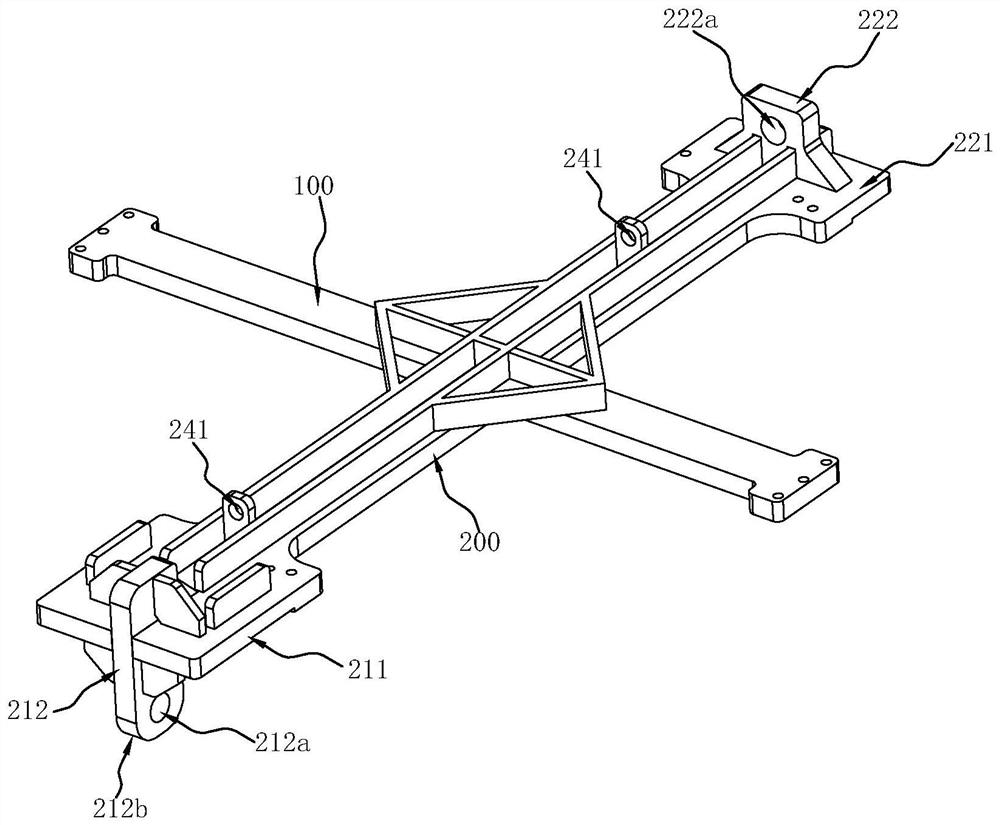

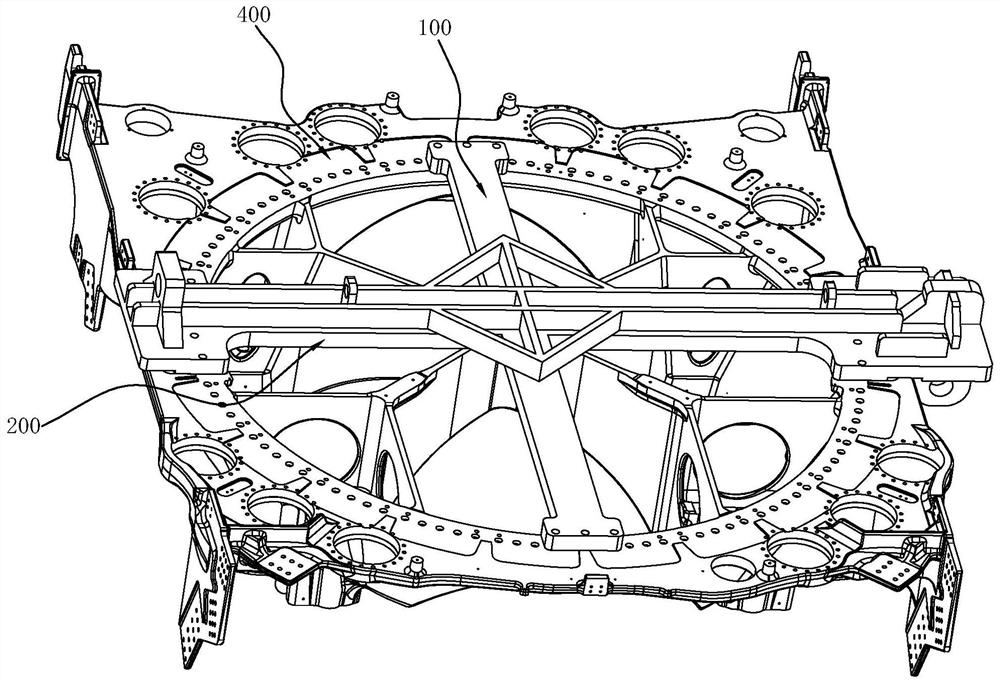

[0031] Please refer to Figure 1-Figure 3 , the invention discloses an integrated device for hoisting and flipping a thin-walled workpiece, comprising:

[0032] The first clamping assembly includes: a first clamping plate 100, two ends of the first clamping plate 100 are respectively provided with a first clamping portion 110 for fixing the workpiece 400;

[0033] The second clamping assembly includes: a second clamping plate 200, the second clamping plate 200 is connected to the first clamping plate 100, and the two first clamping parts 110 are connected to the second The clamping plate 200 is symmetrical, and the second clamping plate 200 is symmetrical about the first clamping plate 100; the first clamping block 210 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com