Auxiliary assembler for vehicle damping rubber

A shock-absorbing rubber and assembler technology, applied in the field of rubber shock-absorbing, can solve problems such as poor use effect, achieve the effects of reducing impact, ensuring stability, and improving shock-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

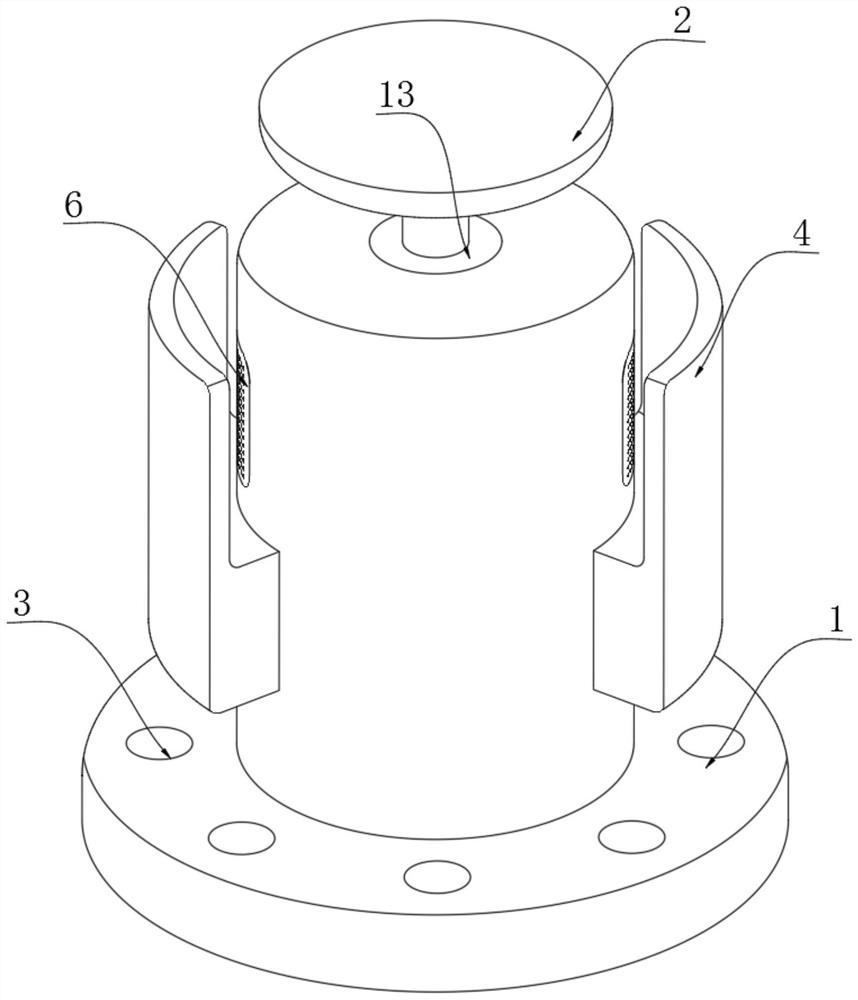

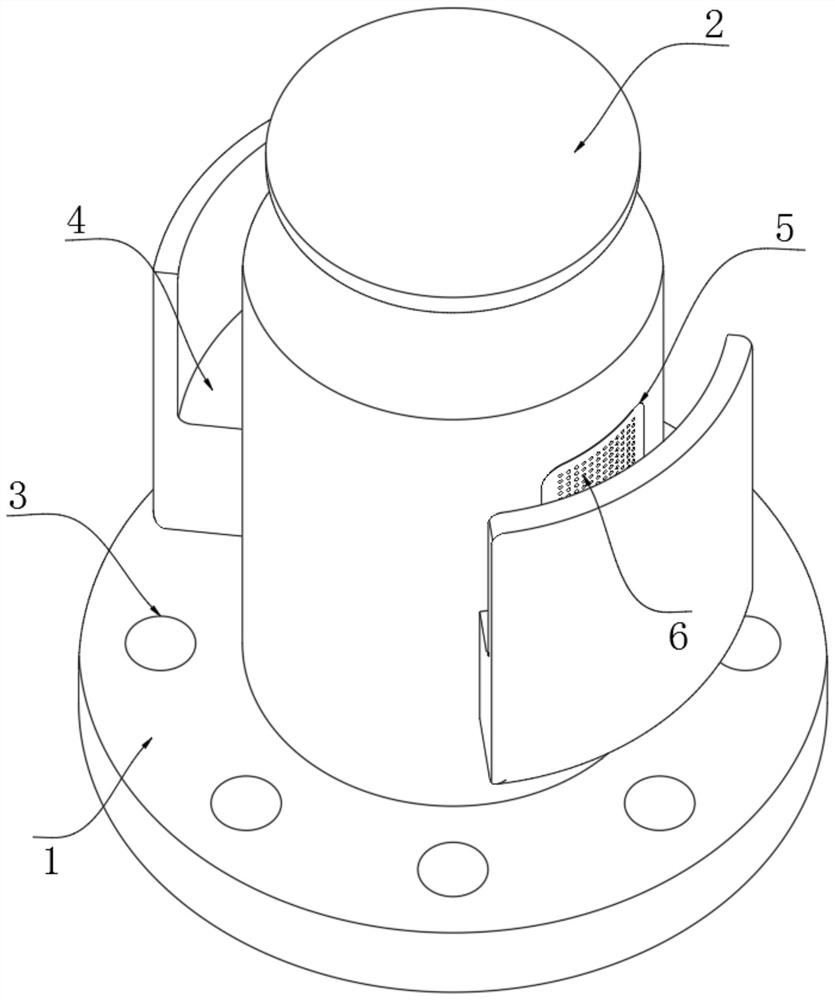

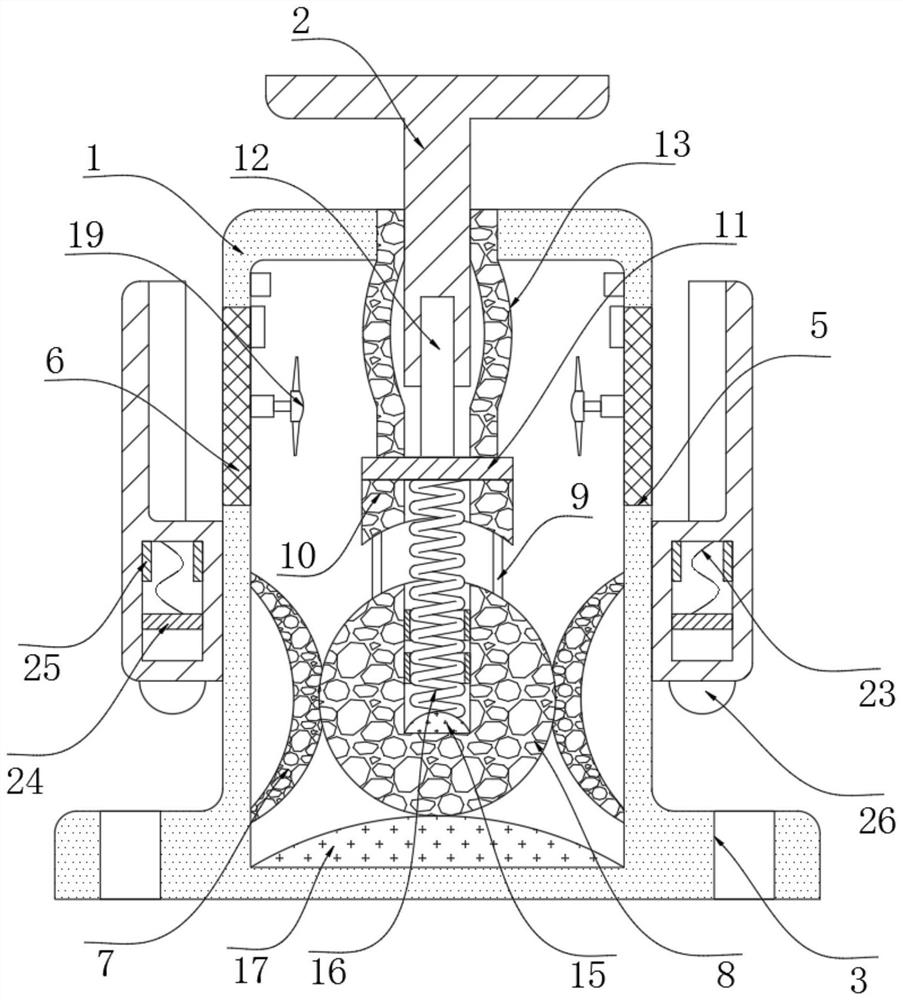

[0028] refer to Figure 1-6 , a shock-absorbing rubber auxiliary assembler for vehicles, comprising a dust cover 1 and an upper connecting body 2, the lower end of the dust cover 1 is provided with a plurality of lower connecting holes 3, and the side wall of the dust cover 1 is symmetrically fixed with two A protective platform 4, the inside of the two protective platforms 4 are equipped with an alarm mechanism, the side wall of the dust-proof cover 1 is provided with two window slots 5, and the inner walls of the two window slots 5 are fixed with filter screens 6, so that the dust-proof The inner wall of the cover 1 is fixed with two mounting rubbers 7, and the side walls of the two mounting rubbers 7 are jointly fixed with a main slowing rubber 8, and the upper end of the main slowing rubber 8 is fixed with a plurality of rubber strips 9, and the upper ends of the multiple rubber strips 9 are common Connected with the upper pressure rubber 10, the upper end of the upper pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com