Automobile main line wheel cover edge pressing system

A technology of hemming and main line, which is applied in the field of wheel cover hemming system of automobile main line, which can solve the problems that the hemming system cannot be well adapted, the fit degree of hemming is poor, and the hemming efficiency is low, so as to achieve low cost, The effect of high hemming beat and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

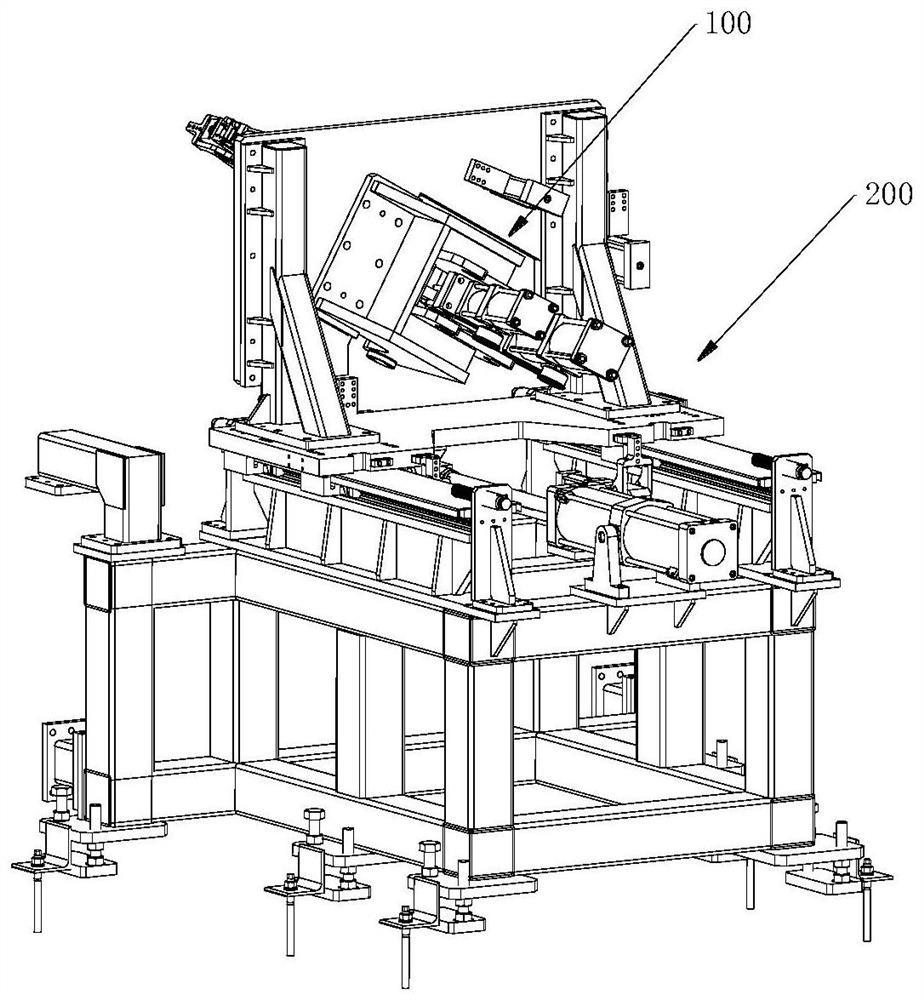

[0037] See Figure 1 to Figure 13 , the present invention has a crimping mechanism 100 for crimping the main line wheel cover of the automobile; the crimping mechanism 100 is installed on a Y-direction adjusting mechanism 200; the Y-direction regulating mechanism 200 drives the crimping mechanism 100 to approach or stay Automobile main line wheel cover;

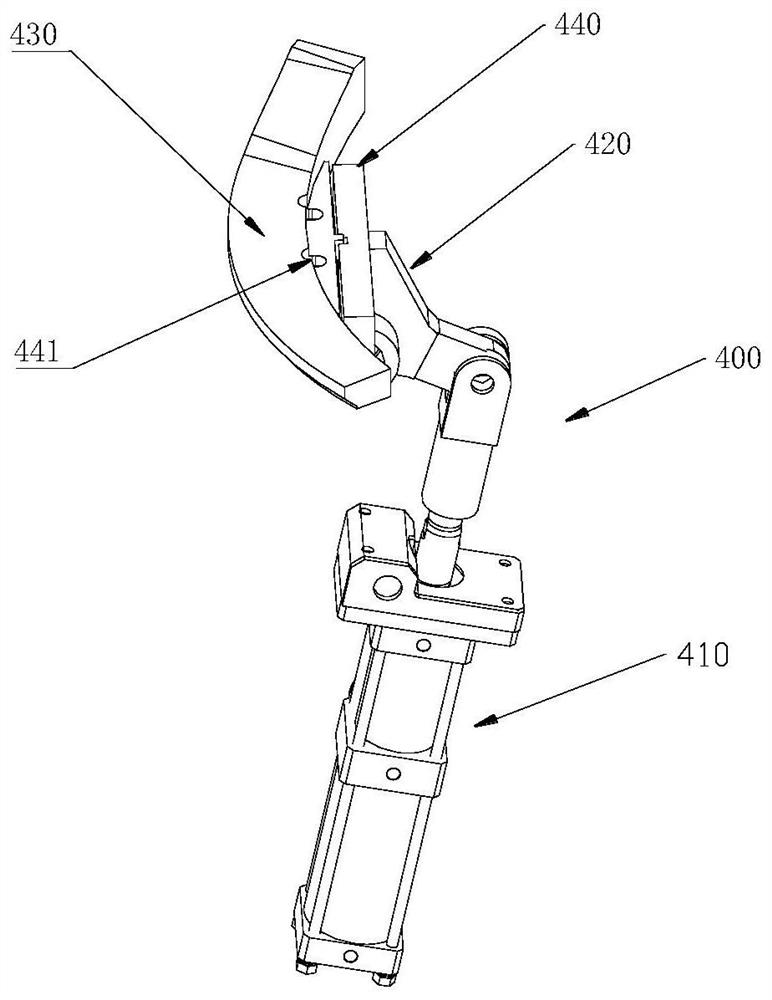

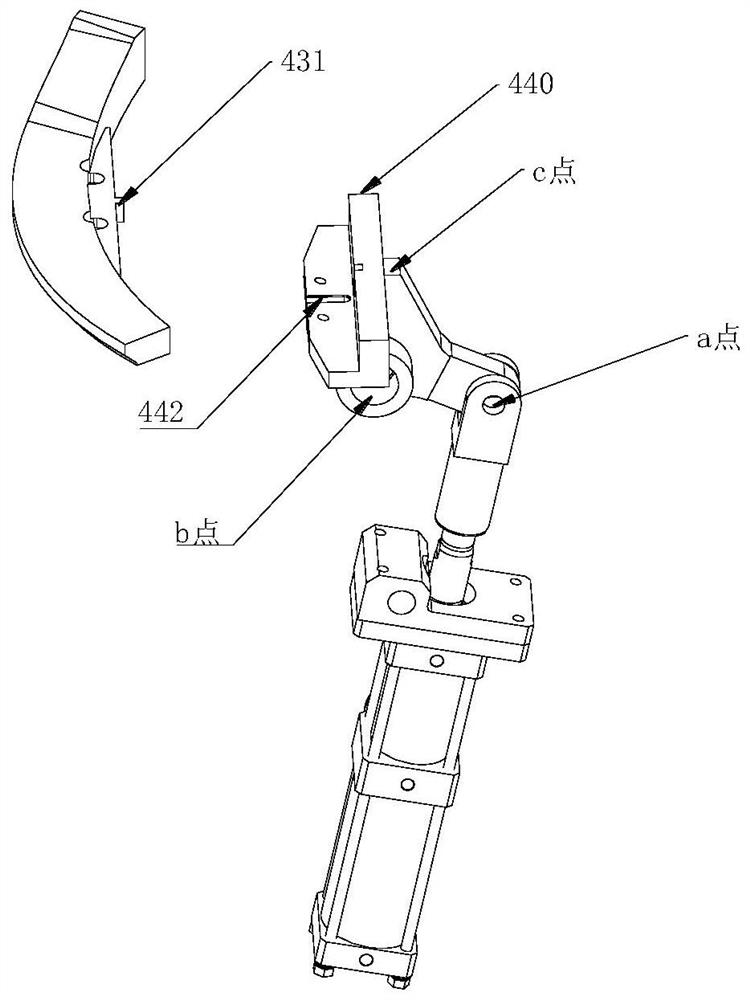

[0038] Described crimping mechanism 100 comprises a crimping mechanism 400 that carries out pre-hemming operation to automobile main line wheel cover and two road crimping mechanisms 500 that carries out final hemming operation to automobile main line wheel cover; Said one crimping mechanism 400 and The second crimping mechanism 500 is installed on the Y-direction adjusting mechanism 200 through the fixing bracket 600 ; the first crimping mechanism 400 is installed inside the second crimping mechanism 500 .

[0039] See figure 2 , in this embodiment, more specifically, the one crimping mechanism 400 includes a driving sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com