Anti-retrogradation glutinous rice pulp

A glutinous rice pulp and glutinous rice technology, applied in food science, frozen desserts, applications, etc., can solve problems such as increasing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

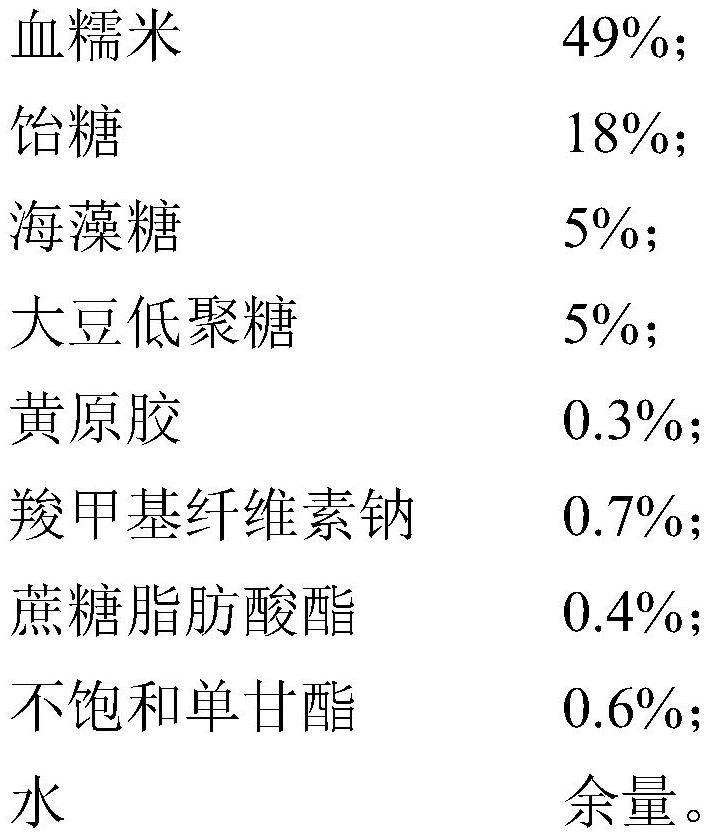

[0053] The component parameters of the anti-reverse blood-forming glutinous rice slurry in the present embodiment are as follows:

[0054]

[0055] The preparation method of the above-mentioned anti-reactive glutinous rice slurry is as follows:

[0056]In the preparation method of the present embodiment, based on the total mass of the product, the sweetener used is prepared by mixing 18% maltose, 5% trehalose and 5% soybean oligosaccharides (that is, based on the total mass of the product On a mass basis, the content of the sweetener is 28%).

[0057] In the preparation method of the present embodiment, based on the total mass of the product, the stabilizer used consists of 0.3% xanthan gum, 0.7% sodium carboxymethyl cellulose, 0.4% sucrose fatty acid ester and 0.6% Prepared by mixing unsaturated monoglycerides.

[0058] Specifically, the following steps are included:

[0059] 1) Pretreatment of blood glutinous rice: Wash the blood glutinous rice, add water (1:3) and coo...

Embodiment 2

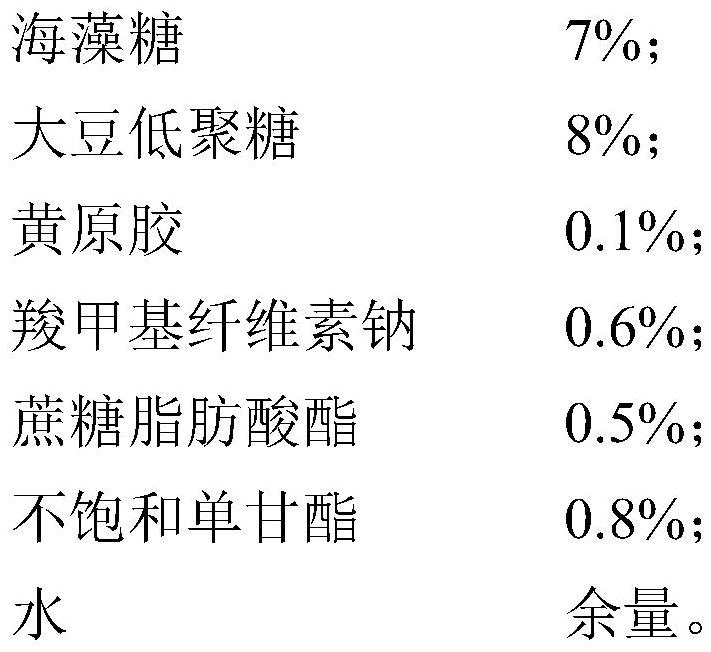

[0067] The component parameters of the anti-reverse blood-forming glutinous rice slurry in the present embodiment are as follows:

[0068]

[0069]

[0070] The preparation method of the above-mentioned anti-reactive glutinous rice slurry is as follows:

[0071] In the preparation method of this embodiment, based on the total mass of the product, the sweetener used is prepared by mixing 15% maltose, 7% trehalose and 8% soybean oligosaccharides.

[0072] In the preparation method of the present embodiment, based on the total mass of the product, the stabilizer used consists of 0.1% xanthan gum, 0.6% sodium carboxymethyl cellulose, 0.5% sucrose fatty acid ester and 0.8% Prepared by mixing unsaturated monoglycerides.

[0073] Specifically, the following steps are included:

[0074] 1) Pretreatment of blood glutinous rice: Wash the blood glutinous rice, add water (1:3) and cook in a sandwich pot until the taste of the blood glutinous rice is soft and cooked; then filter of...

Embodiment 3

[0080] The component parameters of the anti-reverse blood-forming glutinous rice slurry in the present embodiment are as follows:

[0081]

[0082]

[0083] The preparation method of the above-mentioned anti-reactive glutinous rice slurry is as follows:

[0084] In the preparation method of this embodiment, based on the total mass of the product, the sweetener used is prepared by mixing 20% maltose, 3% trehalose and 3% soybean oligosaccharides.

[0085] In the preparation method of the present embodiment, based on the total mass of the product, the stabilizer used consists of 0.4% xanthan gum, 0.9% sodium carboxymethyl cellulose, 0.2% sucrose fatty acid ester and 0.5% Prepared by mixing unsaturated monoglycerides.

[0086] Specifically, the following steps are included:

[0087] 1) Pretreatment of blood glutinous rice: Wash the blood glutinous rice, add water (1:3) and cook in a sandwich pot until the taste of the blood glutinous rice is soft and cooked; then filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com