Magnetic latching relay with large opening distance and high tolerance and high tolerance

A magnetic latching relay and tolerance technology, applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve the problems of small on-off distance, easy generation of continuous arc, poor tolerance and poor reliability of magnetic latching , to achieve the effect of reliable work, not easy to continue the arc, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with accompanying drawing, the present invention will be further described.

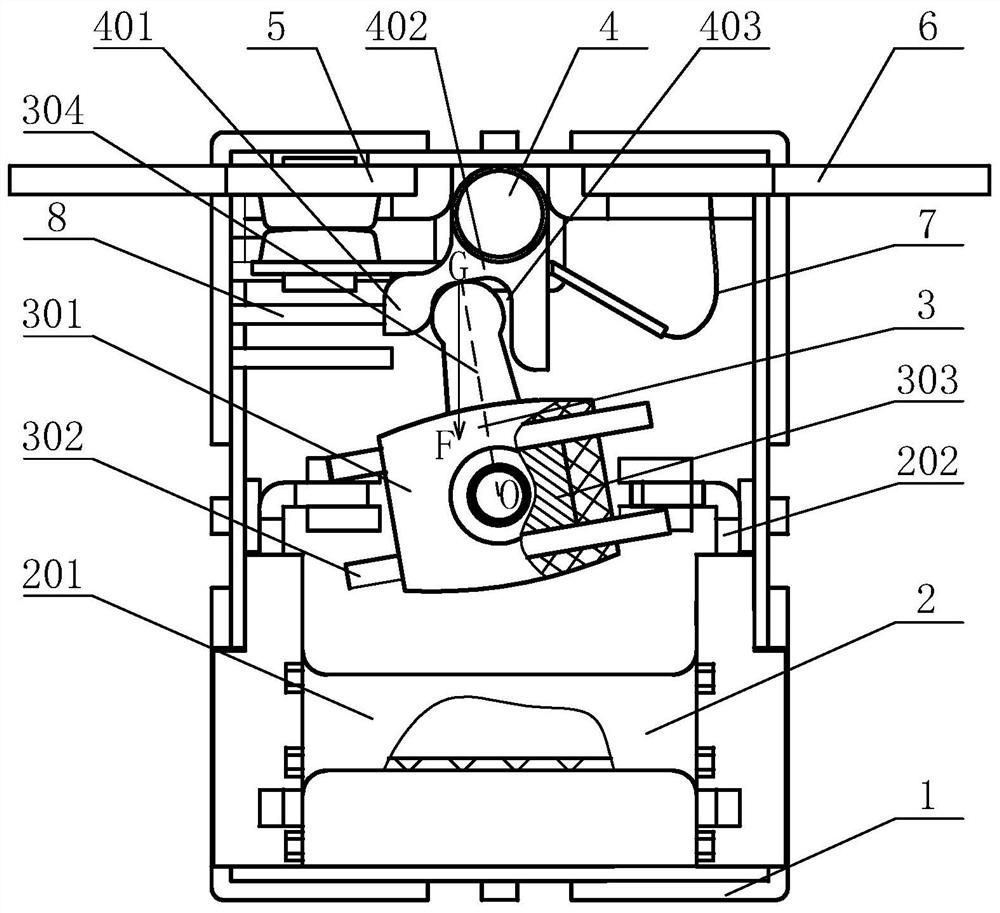

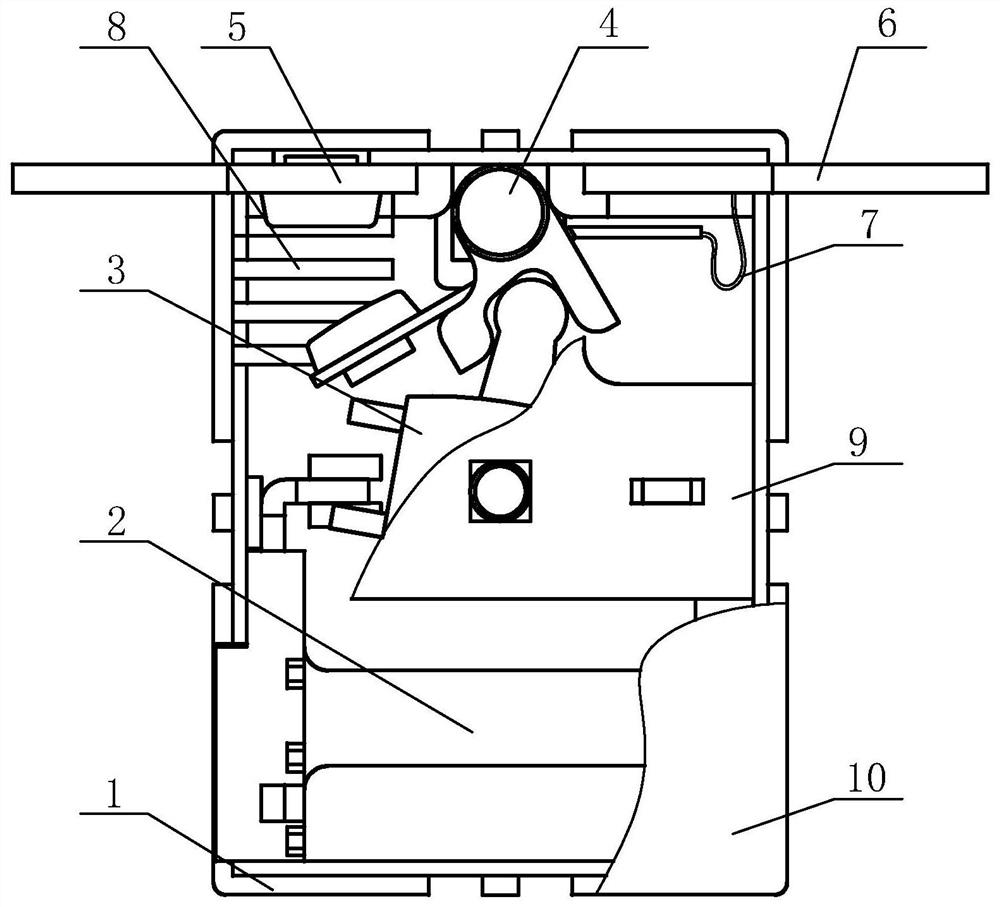

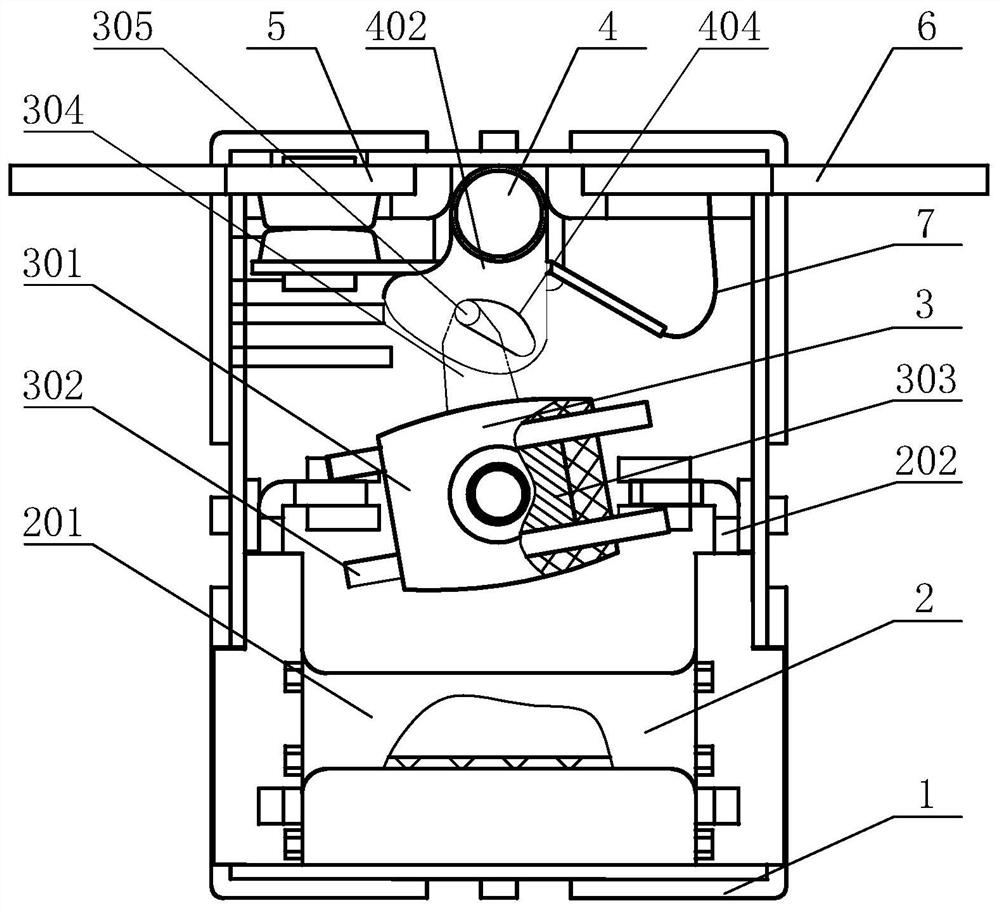

[0022] Such as figure 1 , figure 2 As shown, the magnetic latching relay includes a base 1 and a case 10 , and an electromagnet core assembly 2 , a joystick assembly 3 , a moving plate assembly 4 , a first static piece 5 and a second static piece 6 are respectively arranged in the base.

[0023] The electromagnet core assembly 2 is fixed in the base 1, and includes an electromagnetic coil body 201 with a built-in iron core, and symmetrical yokes 202 are arranged at both ends of the electromagnetic coil body.

[0024] The main body of the joystick assembly 3 is an insulator 301, and the insulator is integrated with a shaft. One end of the shaft is pivoted and pivotally positioned on the base 1, and the other end is pivotally pivoted and positioned on the splint 9 inside the housing 10. The insulator wears Connect and fix two armatures 302 arranged in parallel and at interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com