Track type inspection robot for electric power system

A technology for inspection robots and power systems, applied in the field of inspection robots, can solve the problems of limited data range, the clamping force adjustment mechanism cannot be adjusted in real time, and the information collection device cannot realize all-round detection, so as to improve the data range and increase The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

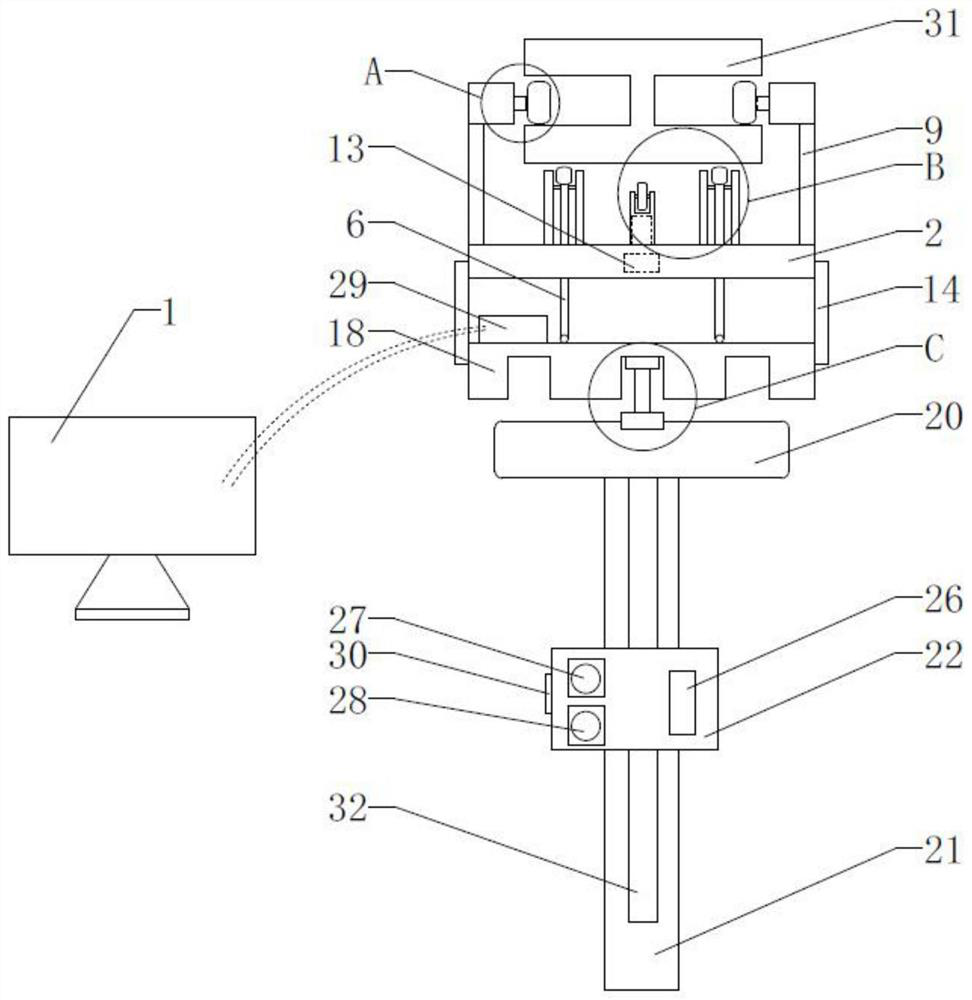

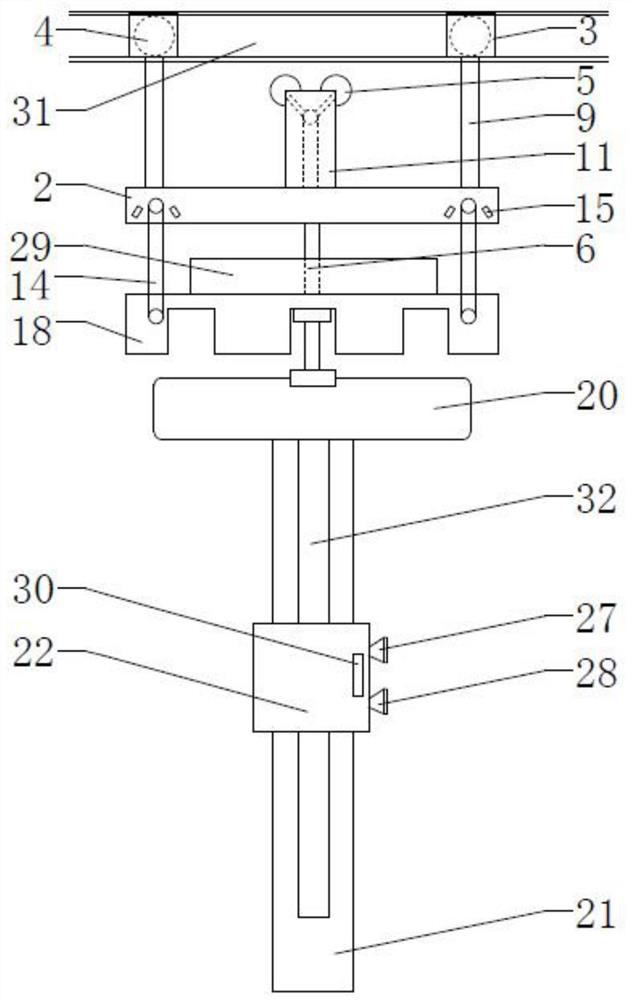

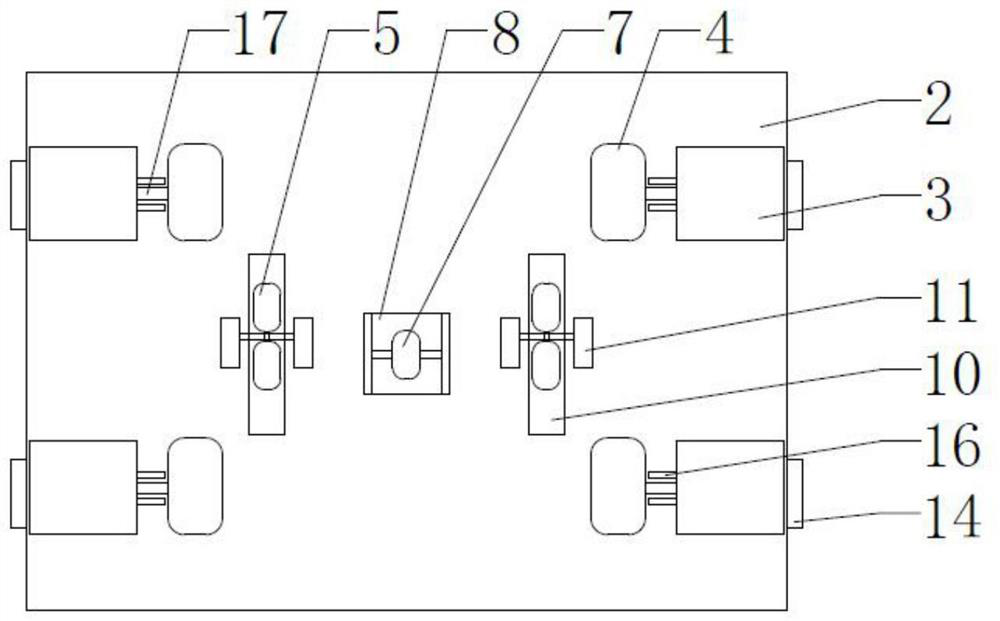

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, a rail-type inspection robot for power systems includes an inspection robot, an inspection track 31 and a main control center 1 . The inspection track 31 is set in the power system factory to provide the running track for the inspection robot. The inspection track 31 is an I-shaped track; the main control center 1 communicates with the inspection robot; the inspection robot is hoisted on the inspection track 31.

[0057] The inspection robot includes a driving module, a clamping module, a direction adjustment module and a detection module; the driving module is connected to the inspection track 31, and transports the inspection robot to the front of the equipment to be inspected; the clamping module is set Under the inspection track 31, it is used to adjust the clamping force between the inspection track 31 and the inspection robot; the direction adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com