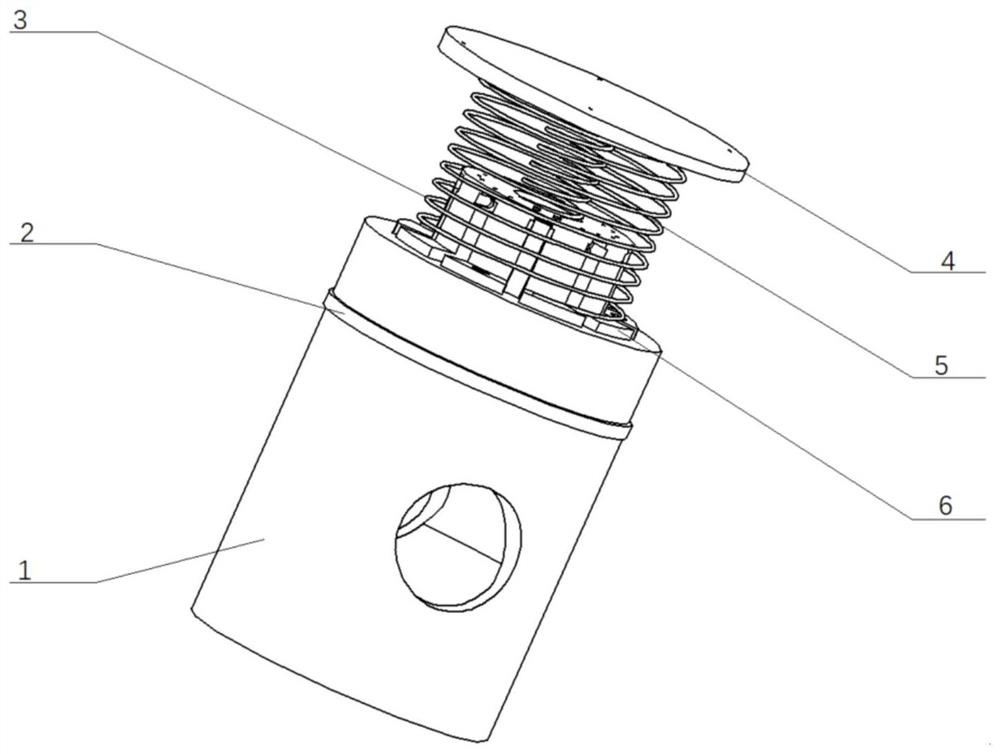

Piston ring circumference radial elastic force dynamic testing device

A technology for dynamic testing and piston rings, applied in measuring devices, elastic testing, force/torque/power measuring instruments, etc., can solve the problems of large measurement errors, low detection efficiency, low repeatability, etc., to reduce measurement errors, The effect of improving measurement accuracy and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

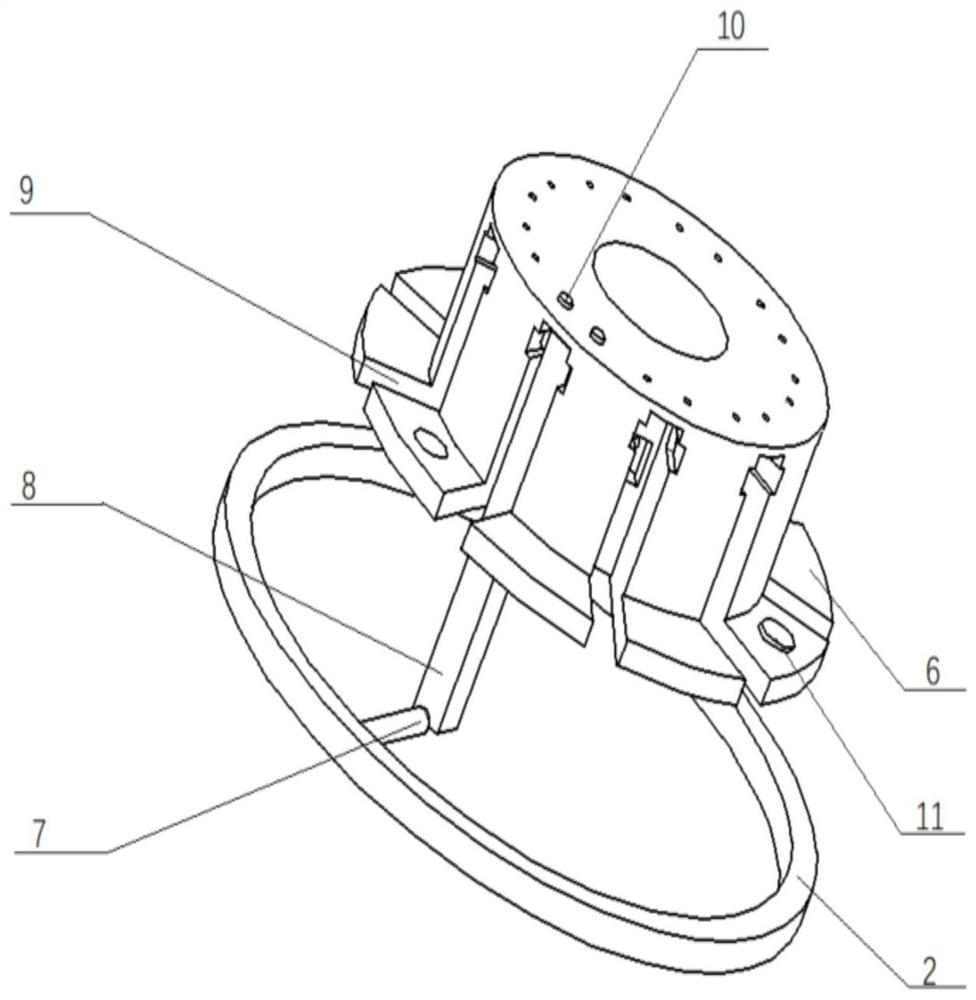

Method used

Image

Examples

specific Embodiment approach

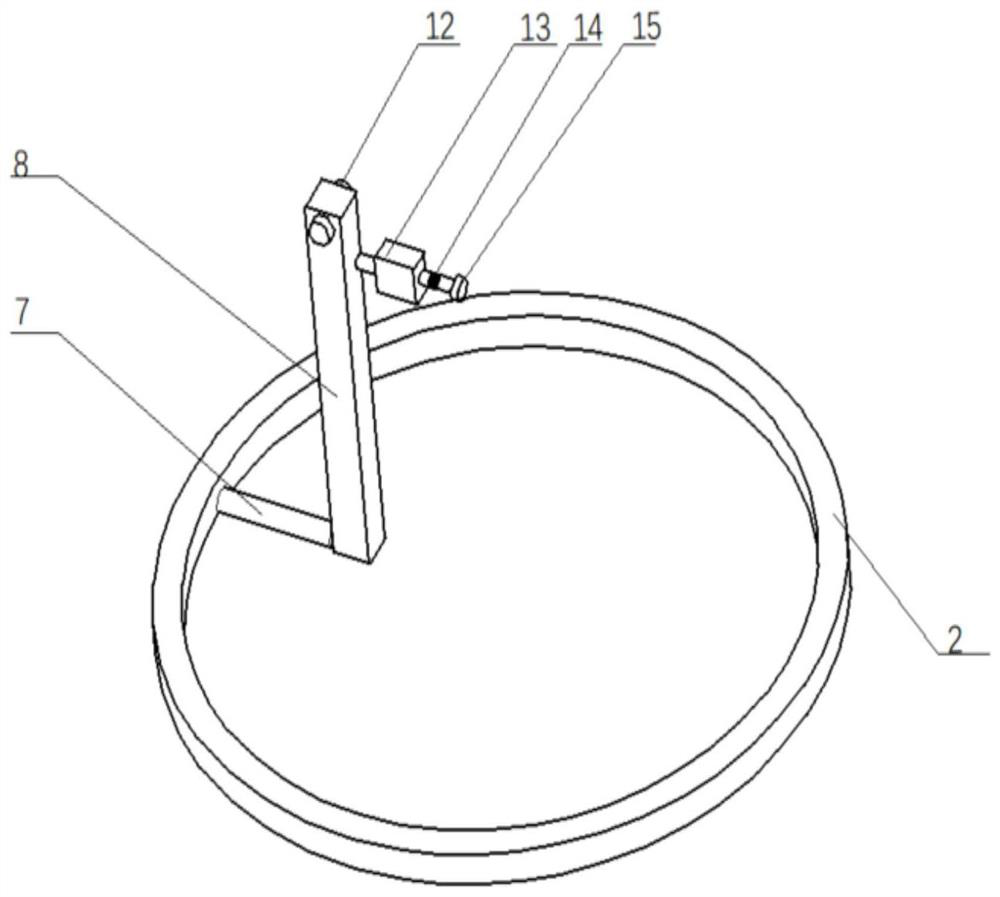

[0046] Specific implementation method: adjust the first adjusting screw 16 to ensure that the first load cell 17 displays an extremely small value, adjust the second adjusting screw 19 to ensure that the second load cell 18 displays and its small value, and ensure that the two sensors and the floating measuring block 20 contact, and then install the piston-piston ring device into the cylinder 22, the floating measuring block 20 is in contact with the piston ring 2, observe the values of the first load cell 17 and the second load cell 18 at this time, the difference between the two display values and is the radial elastic force value at this point in the circumferential direction of the piston ring 2. If the value is within the reasonable range of the radial elastic force of the piston ring 2, it means that when the piston ring 2 is static and installed in the working position, the force is more reasonable. The design of the ring 2 type line is preliminarily judged to be reaso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com