Sludge high-temperature wall-breaking conditioning machine, wall-breaking conditioning dehydration system and method

A technology of conditioning machine and wall breaking machine, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., which can solve the problems of increased processing difficulty, high operating cost, and high drying cost. problems, to achieve the effect of improving adjustability and dehydration, simple process flow and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

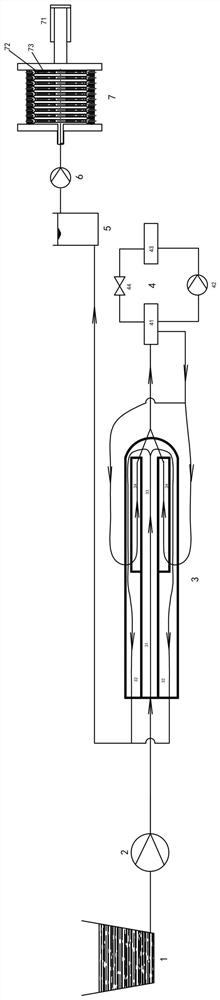

[0030] The present invention includes three aspects. First, the first aspect includes a sludge high-temperature wall-breaking conditioner. For the sludge high-temperature wall-breaking conditioner, see figure 1 , including interconnected high-temperature sludge breakers and sludge conditioning tanks, in this embodiment, see figure 1 As shown, the high-temperature sludge breaker has a three-layer structure, the middle layer includes a pre-heating chamber, and the pre-heating chamber is provided with a working fluid heat exchange chamber at the corresponding position of the adjacent two layers, and the hydrolysis and wall breaking The chambers are respectively connected to the preheating chamber of the middle layer and the working fluid heat exchange chambers of the two adjacent layers, and a heating device is installed in the hydrolysis chamber to heat and break the sludge in the hydrolysis chamber , because the working fluid heat exchange chamber and the preheating chamber are...

Embodiment 2

[0035] In Embodiment 2 of the present invention, a sludge high-temperature wall-breaking conditioning and dehydration system is provided, which includes a sludge high-temperature wall-breaking conditioner described in Example 1, and the sludge high-temperature wall-breaking conditioner The high-temperature sludge breaker is connected to the wet sludge silo, which contains a large amount of sludge with a water content of about 80%. These sludge may have passed through the existing belt dehydrator or centrifugal dehydrator in advance. The sludge conditioning tank is connected to the plate and frame dehydrator, and the sludge with a water content of about 90% after the wall breaking is further dehydrated to 50% to 60% in the plate and frame dewaterer. Compared with the drying cost required to directly dry the sludge with a water content of about 80% to a water content of 50% to 60%, the technical solution adopted in this example adopts the dehydration method of mechanical dehydrat...

Embodiment 3

[0037] Embodiment 3 Through a kind of sludge high-temperature wall-breaking conditioning and dehydration system provided in Example 2, implement a sludge high-temperature wall-breaking conditioning and dehydration method, including the following steps:

[0038] S1. Put the sludge with a water content of 80% into the preheating chamber of the sludge high-temperature wall-breaking conditioner through the sludge feed pump to preheat the sludge;

[0039] S2. The preheated sludge continues to move forward and enters the hydrolysis and wall breaking chamber of the sludge high temperature wall breaking conditioner to further heat the sludge. After a period of high temperature and high pressure, the cell walls of a large number of cells in the sludge are broken and released intracellular water;

[0040] S3. The broken sludge further enters the working medium heat exchange chamber, exchanges heat with the preheating chamber, and cools the sludge to a temperature close to that at the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com