Full-automatic packaging process for hard board products

A fully automatic packaging and rigid board technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as poor packaging and low packaging efficiency, and achieve the effect of improving packaging efficiency and realizing fully automatic packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

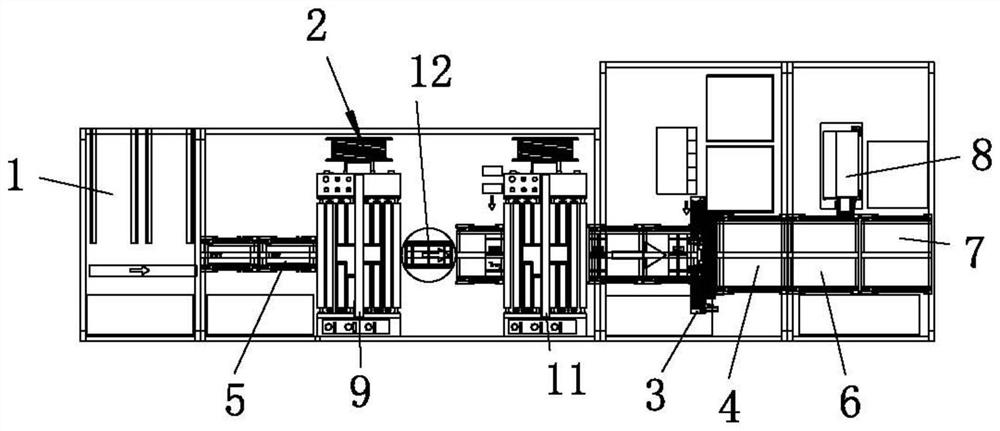

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

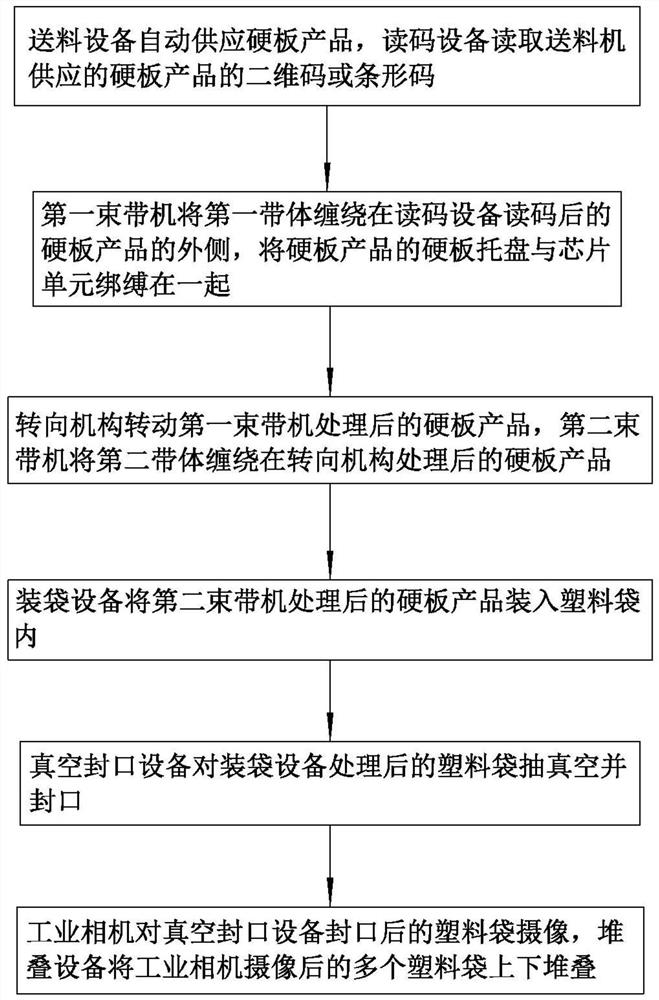

[0034] see Figure 1 to Figure 3 Shown, a kind of full-automatic packing process of rigid board product of the present invention, comprises the steps:

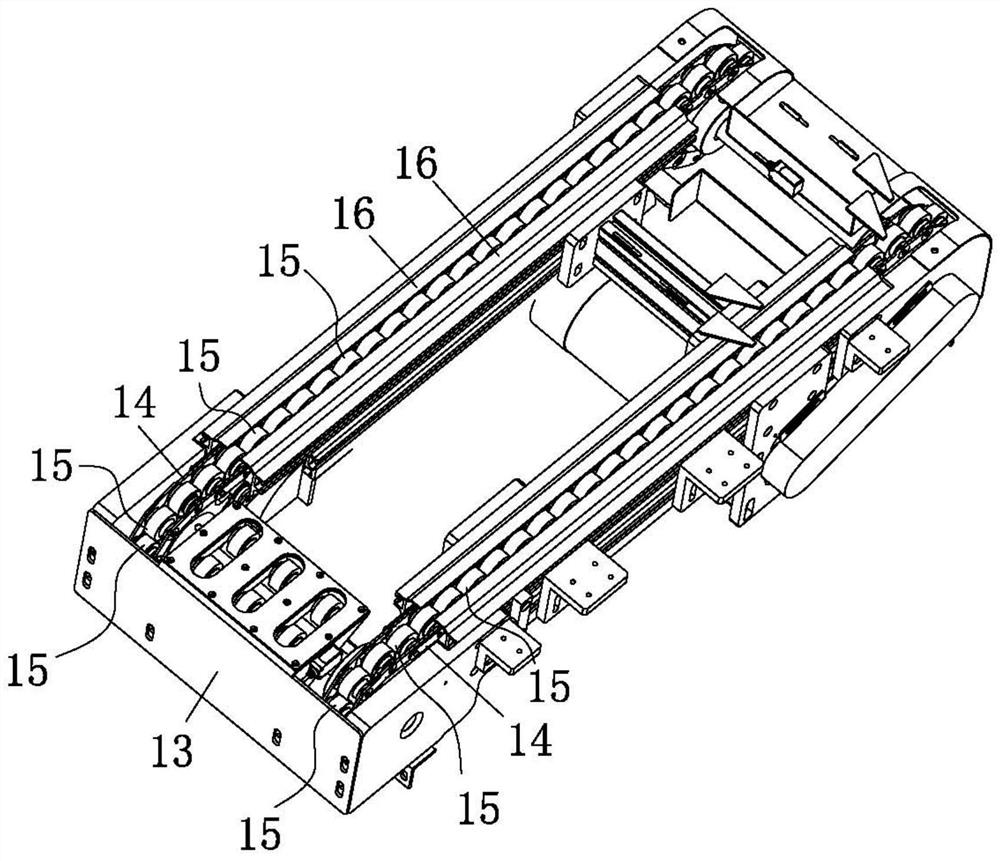

[0035] Utilize the feeding device 1 to automatically input hard board products. The hard board products include chip units and hard board trays for carrying chip units. The hard board trays have limiting blind slots for accommodating chip units. The side of the groove stops and limits the chip unit to prevent the chip unit from moving relative to the hard board tray;

[0036] In this embodiment, the hard board tray is made of hard materials. For example, the hard board tray is made of hard plastic. With the help of the hard board t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com