Full-automatic workpiece cleaning device for mechanical engineering

A technology for mechanical engineering and cleaning devices, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc. It can solve the problems of fixed structure and function, single structure, weak intelligence, etc., so as to improve the cleaning effect. , Improve cleaning efficiency, strengthen the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

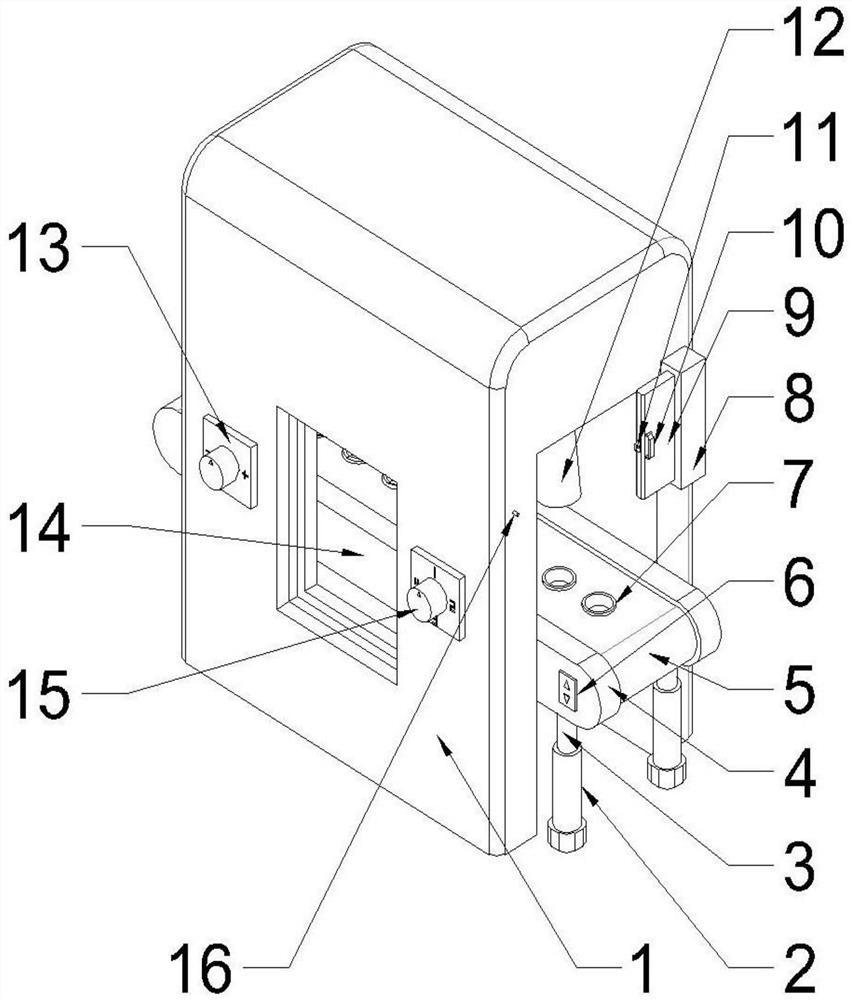

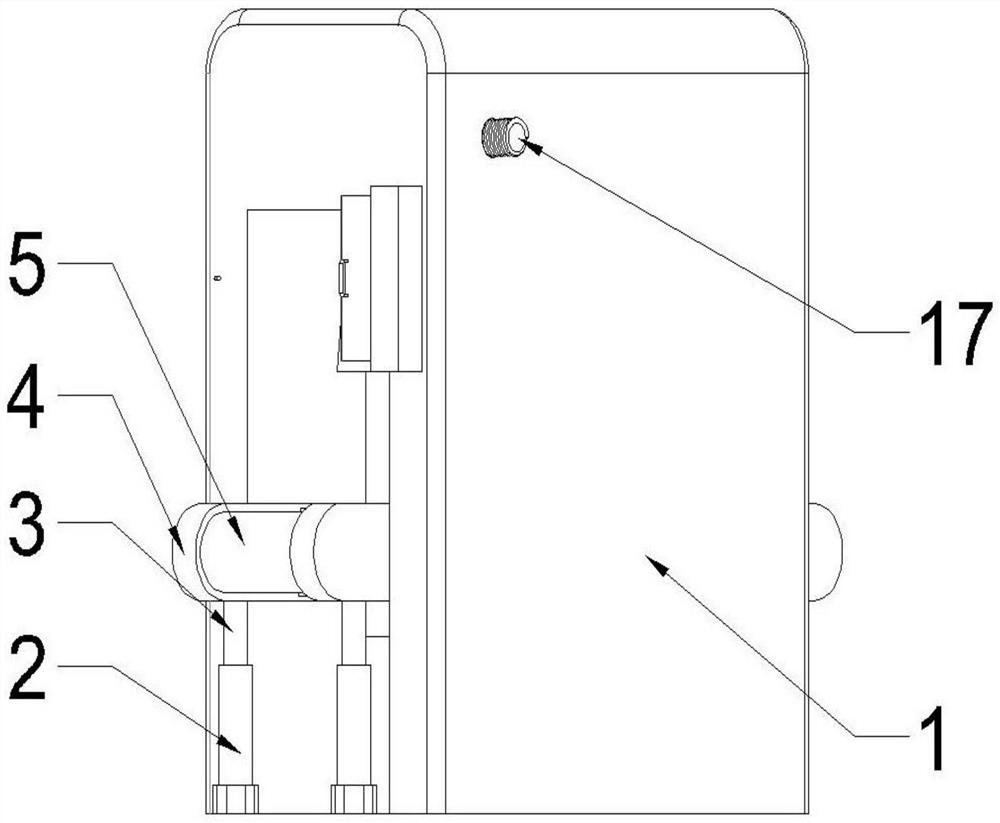

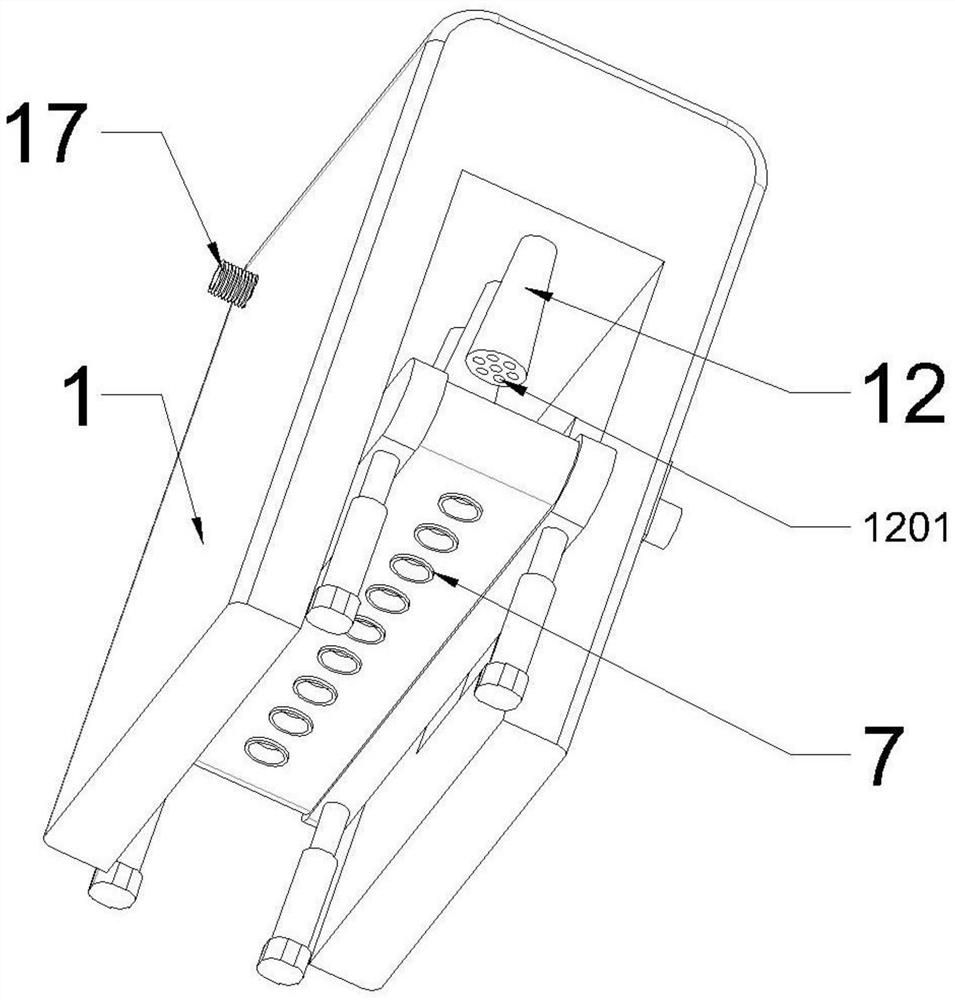

[0027] see Figure 1 to Figure 7 , a fully automatic workpiece cleaning device for mechanical engineering, comprising an installation box 1, a fixed column 2 is arranged inside the installation box 1, a lifting column 3 is arranged above the fixed column 2, a crawler installation body 4 is arranged above the lifting column 3, and the crawler installation A crawler 5 is arranged between the bodies 4, a rotatable workpiece groove 7 is arranged on the crawler 5, a column lifting button 6 is arranged on the front side of the crawler installation body 4, a spraying pipe 12 is arranged above the crawler 5, and a spraying pipe 12 is arranged on the spraying pipe 12. Spray holes 1201, a glass window 14 is arranged inside the front side of the installation box 1, a water volume adjustment knob 13 is arranged on the left side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com