A super wide-angle fully automatic aa equipment

A fully automatic, ultra-wide-angle technology, applied in TV, coating, pre-treatment surface, etc., can solve the problems of long cycle process, poor compatibility, unable to guarantee the focus environment, etc., to improve work efficiency, fast switching, and increase practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

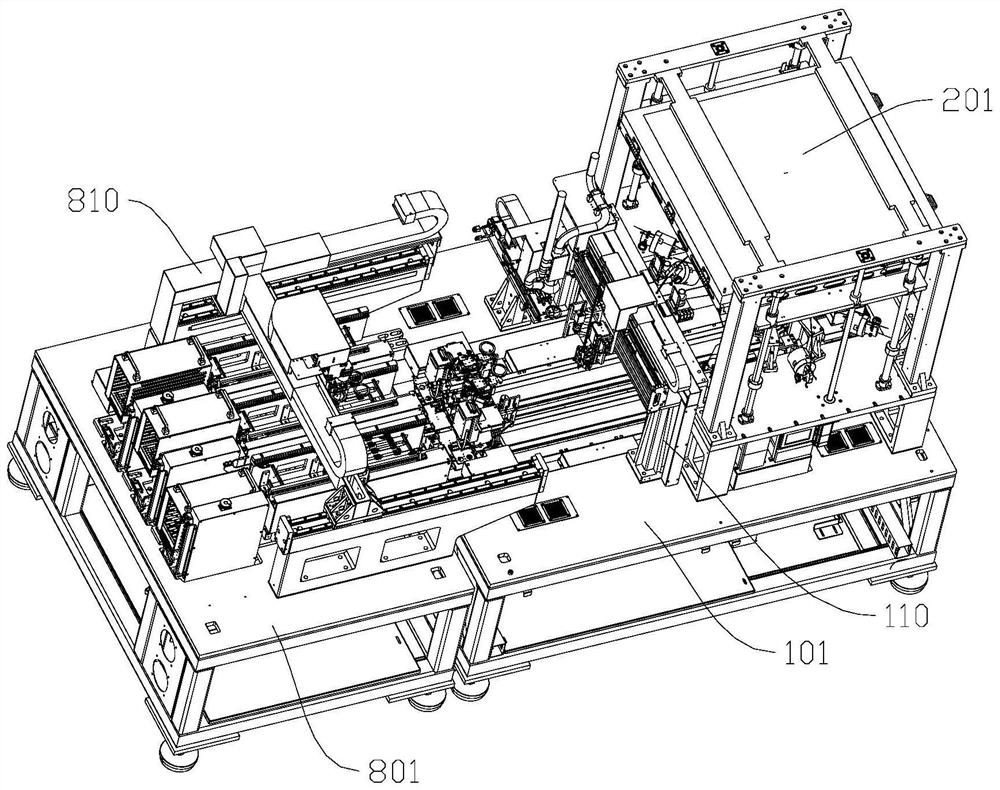

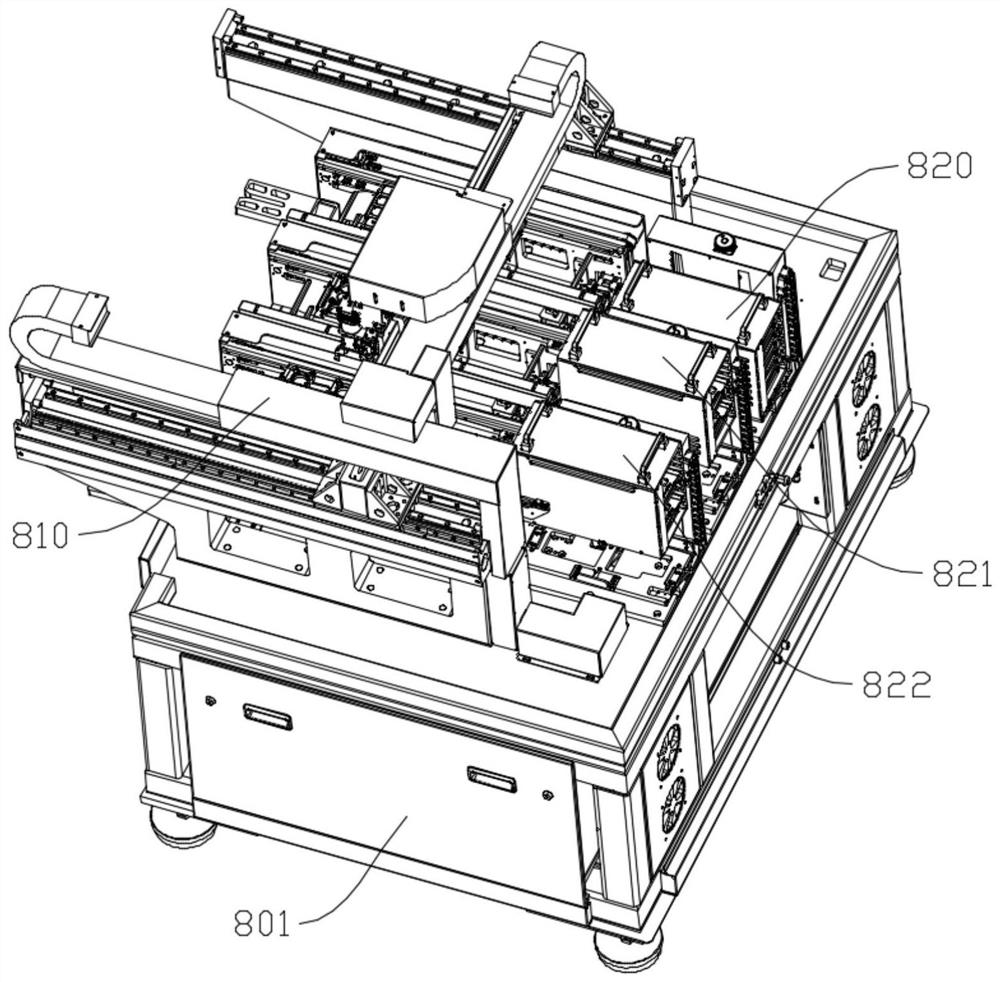

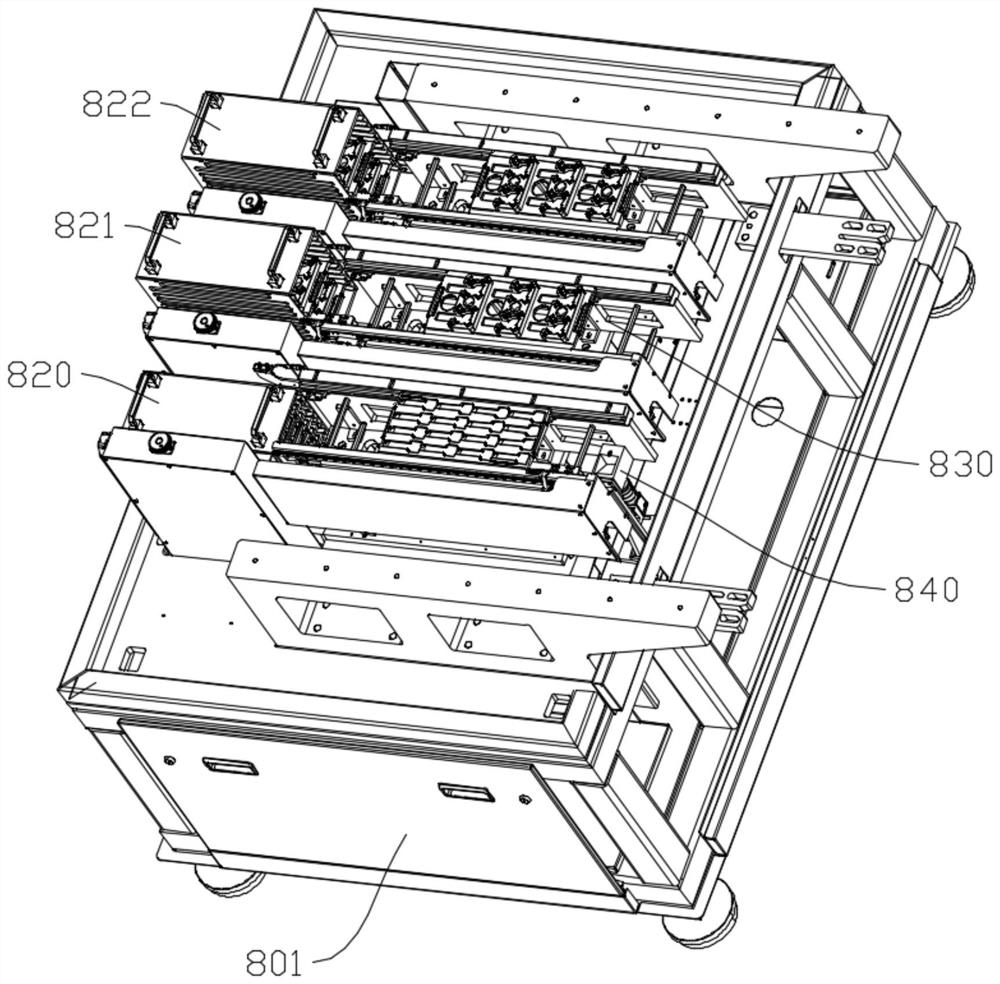

[0060] like Figure 1-Figure 24 As shown, the present invention discloses an ultra-wide-angle fully automatic AA device, which includes: a feeding table bracket 801, the front end of the feeding table bracket 801 is equipped with a PCBA magazine box 820, a multi-purpose magazine box 821 and NG bombs Clip box 822, the multi-purpose clip box 821 is used to fill the lens and reflow finished products, the feeding table bracket 801 is provided with the PCBA clip box 820, the multi-purpose clip box 821 and the NG clip box 822 corresponds to the feeding tray 830, which is used to transport raw materials and finished products;

[0061] Gantry feeding assembly 810, see Figure 2-Figure 4 , the gantry feeding assembly 810 is installed on the feeding platform support 801, the gantry feeding assembly 810 is provided with a gantry support 811, and the gantry support 811 is provided with a gantry X-axis guide rail 812 and a gantry X-axis driving assembly 813, the gantry Y-axis assembly 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com