A multi-frequency ultrasonic flotation bubble-enhanced mineralization device

A multi-frequency, ultrasonic technology, used in flotation, utilizing vibrating fluids, improving process efficiency, etc., can solve problems such as environmental pollution, and achieve the effect of large working area, good sealing performance, and excellent tensile performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

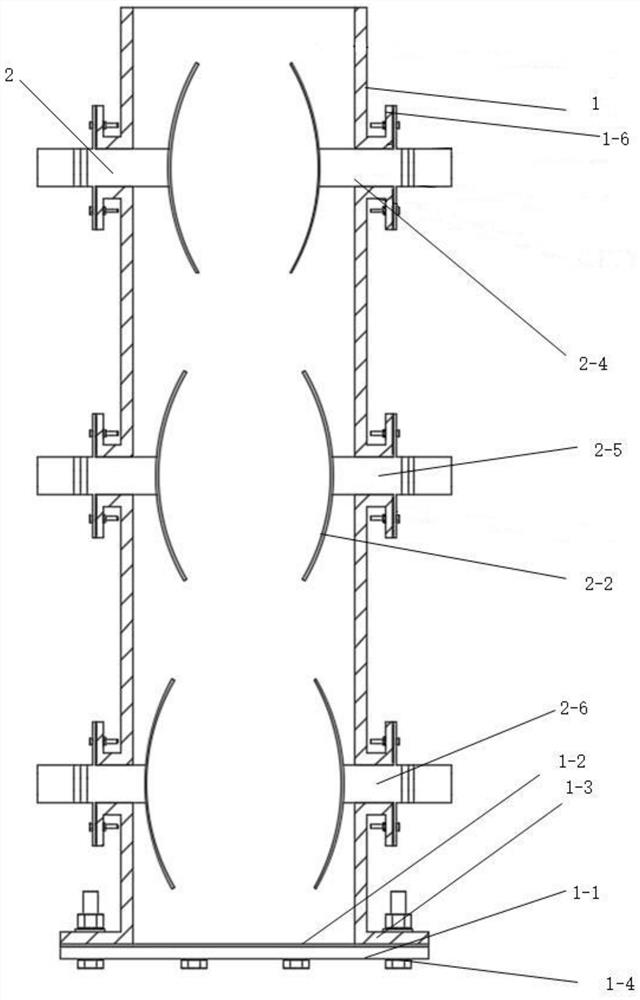

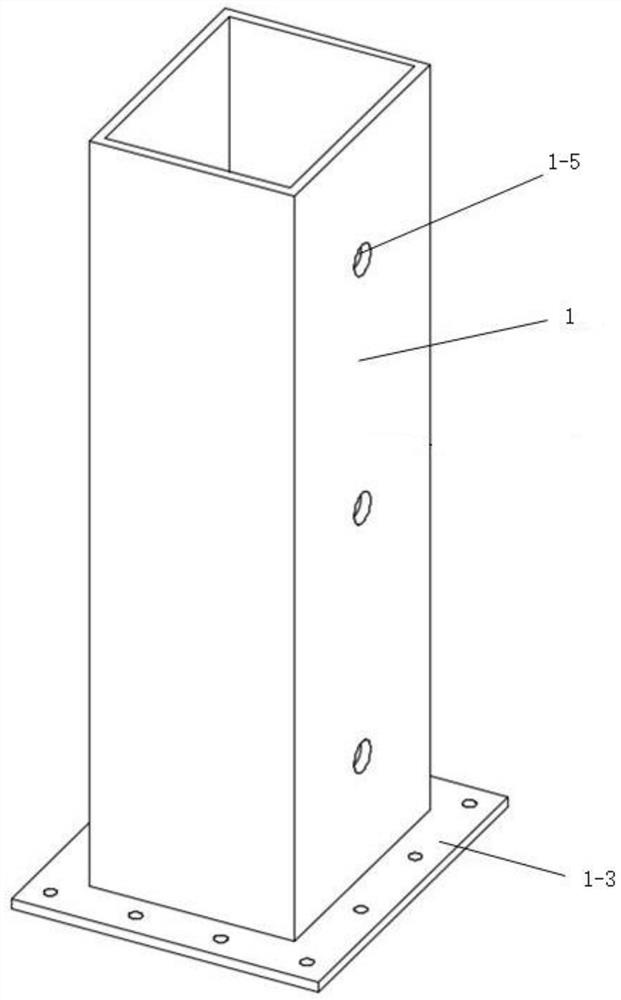

[0021] Such as Figure 1 to Figure 5 As shown, a multi-frequency ultrasonic action flotation bubble enhanced mineralization device, its main body is a cuboid pulp tank 1, the bottom of the pulp tank 1 is provided with a supporting plate 1-1, and the supporting plate 1-1 is provided with There is a sealing rubber plate 1-2, the material of the sealing rubber plate 1-2 is styrene-butadiene rubber, and the supporting plate 1-1 and the bottom edge 1-3 of the pulp tank body 1 are fixed and sealed by bolts 1-4. The geometric center of the support plate 1-1 is provided with an array of through holes with a diameter less than or equal to 1mm, which are used to feed flotation air bubbles, so that the air bubbles escaping from the needle of the air bubble generator can be evenly distributed.

[0022] On the opposite sides of the slurry tank body 1, three sets of ultrasonic exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com